Simulation method of heat conducting fluid in heating furnace

A simulation method and heat-conducting fluid technology, applied in design optimization/simulation, image data processing, special data processing applications, etc., can solve problems such as complex operation process and long time-consuming grid division, and achieve simple operation and great practical application value , the effect of shortening the simulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

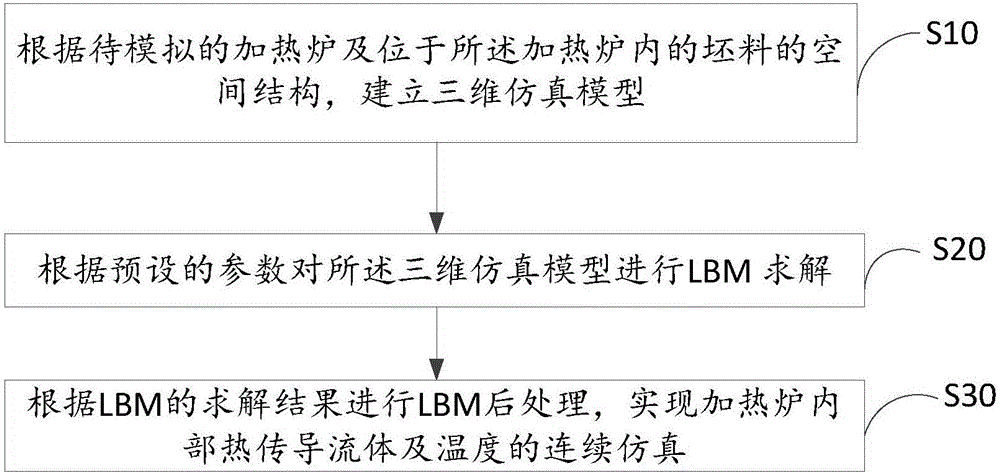

[0040] like figure 1 As shown, the present invention provides a method for simulating heat transfer fluid in a heating furnace, comprising the following steps:

[0041] Step S10, establishing a three-dimensional simulation model according to the heating furnace to be simulated and the spatial structure of the billet located in the heating furnace;

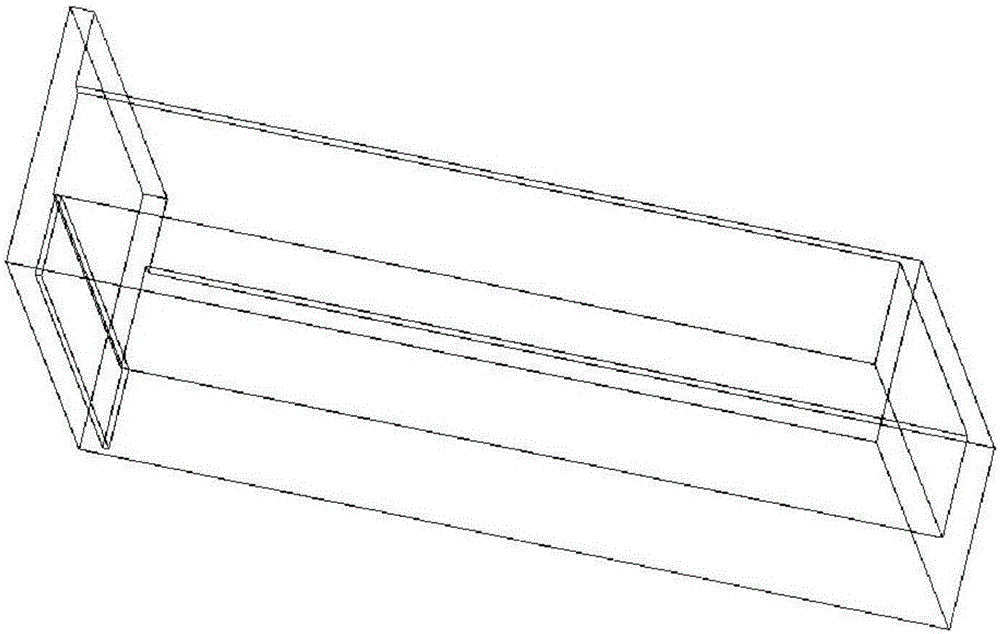

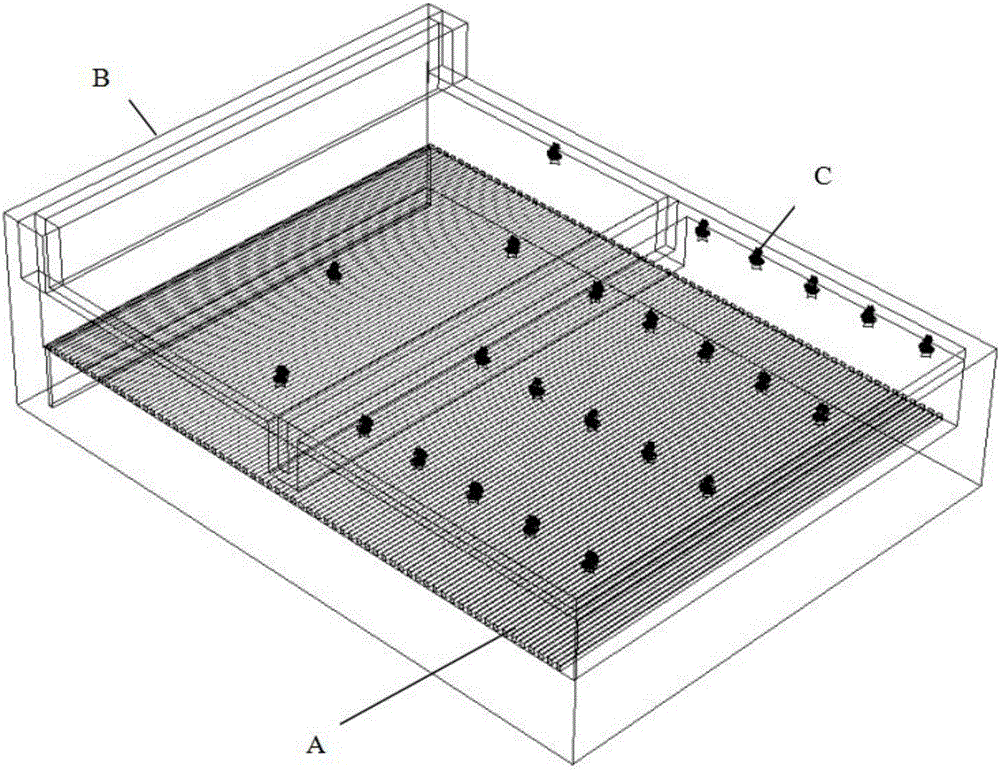

[0042] First, establish a 3D simulation model of the heating furnace according to the spatial structure of the heating furnace to be simulated. For details, see figure 2 , and then establish the three-dimensional simulation model of the blank according to the spatial structure of the blank and the positional relationship of the blank in the heating furnace. For the spatial structure of multiple flat flame burners C see image 3 , modeling can be realized through 3D graphics software.

[0043] Step S20, performing an LBM solution to the three-dimensional simulation model according to preset parameters;

[0044] After importing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com