Method and device for obtaining process parameters of nickel-based alloy pipe hot extrusion

A technology of process parameters and nickel-based alloys, which is applied in the field of pipe hot extrusion, can solve the problems of large consumption of tube blanks, high cost and waste of resources, and ineffective guidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

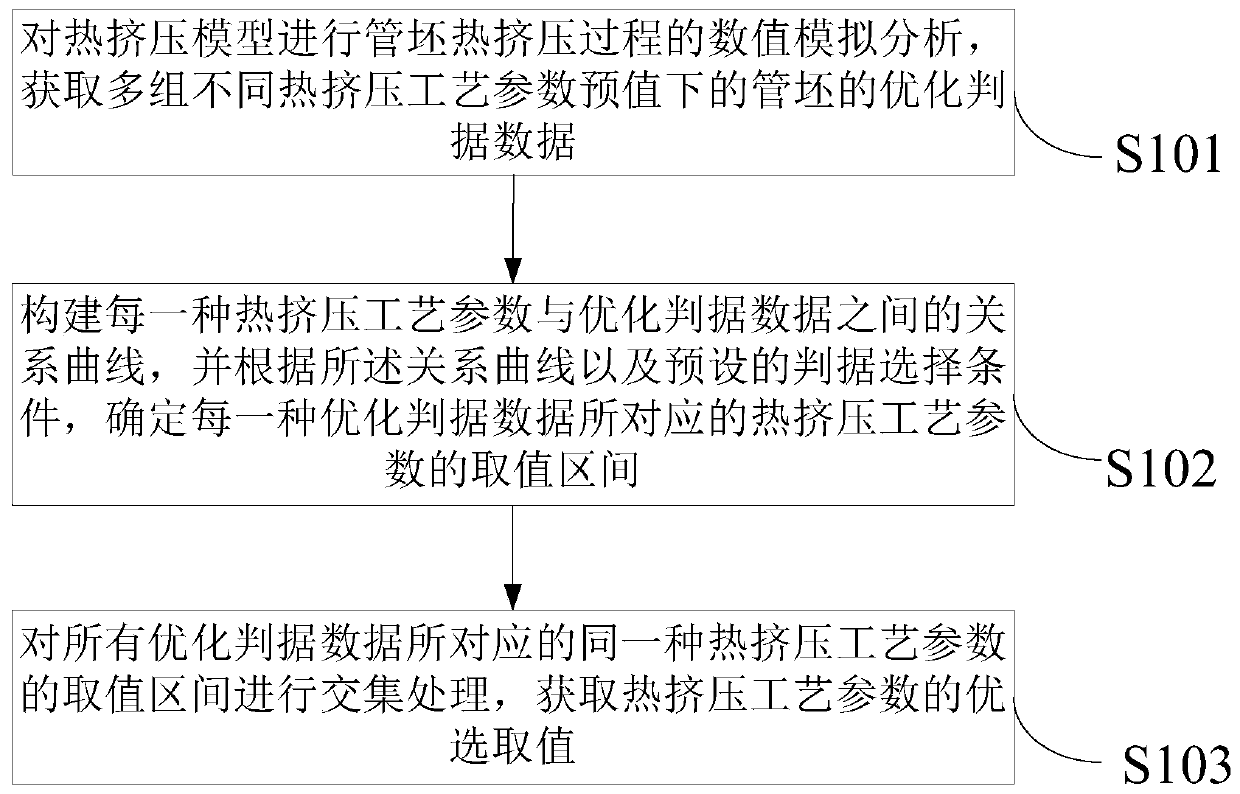

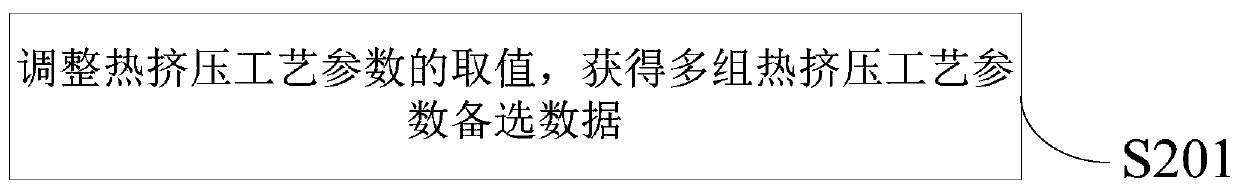

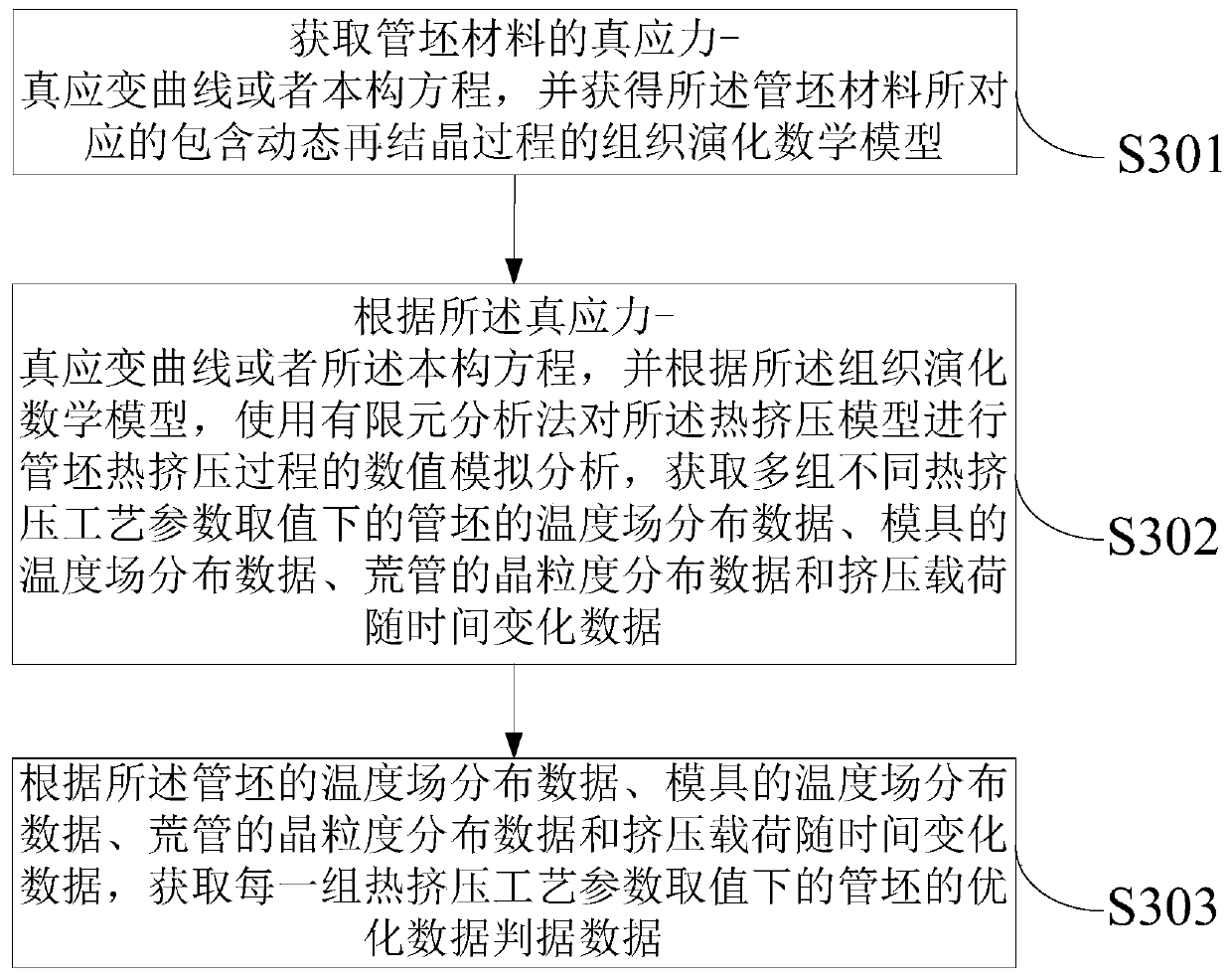

Method used

Image

Examples

Embodiment 1

[0104] In this example, the numerical simulation method is used to optimize the hot extrusion process parameters of the nickel-based superalloy In740H alloy pipe.

[0105] The chemical composition weight percent of the superalloy In740H described in this example is C≤0.05%, Cr: 23-26%, Co: 19%-21%, Mo: 0.4-0.7%, Fe≤1.0%, Al : 0.8 to 1.6%, Ti: 1.0 to 2.0%, Nb: 1.0 to 2.0%, Ni: the balance.

[0106] According to purpose and working principle described in the present invention, concrete technical scheme is:

[0107] The high-temperature compression test samples were taken from the 1 / 2 radius of the In740H alloy forging rod and processed into a Φ8×12mm cylinder. The high-temperature compression test was carried out on a Gleeble thermal simulation testing machine, and the thermal compression temperatures were selected at 1000°C, 1050°C, 1100°C and 1150°C. ℃, the strain rate is selected as 0.1s-1, 1s-1 and 10s-1, the compression true strain is 0.16, 0.35, 0.7 and 0.9, a total of 48...

Embodiment 2

[0118] In this example, the numerical simulation method is used to optimize the hot extrusion process parameters of the nickel-based corrosion-resistant alloy In690 alloy pipe.

[0119] The chemical composition weight percent of the corrosion-resistant alloy In690 described in this embodiment is C≤0.05%, Cr: 27-31%, Fe: 7%-1.0%, Si≤0.5%, Cu≤0.5%, Ni: margin.

[0120] According to purpose and working principle described in the present invention, concrete technical scheme is:

[0121] The high-temperature thermal compression test sample is taken from the 1 / 2 radius of the In690 alloy forging rod and processed into a Φ8×12mm cylinder. The high-temperature compression test is carried out on the Gleeble thermal simulation testing machine, and the thermal compression temperature is 1050 ° C, 1100 ° C, 1150 ° C and 1200 ℃, the strain rate is selected as 0.1s-1, 1s-1 and 10s-1, the compression true strain is 0.16, 0.35, 0.7 and 0.9, a total of 48 sets of deformation conditions are ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com