Auxiliary device for testing explosive velocity of explosive

An auxiliary device and detonation velocity technology, applied in the direction of measuring devices, fuel oil testing, instruments, etc., can solve the problems that affect the accuracy of detonation velocity test results, cannot ensure that the probes are completely parallel, and the impact of detonation velocity, etc., so as to facilitate popularization and application and occupy a small volume , Improve the effect of stability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

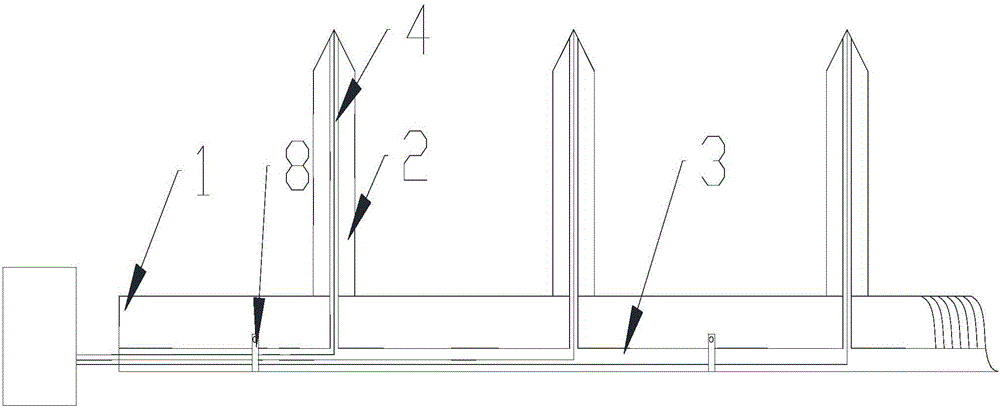

[0022] Embodiment one: if figure 1 , figure 2 and image 3 As shown, an auxiliary device for explosive detonation velocity testing includes a cylindrical rod body 1 made of PVC material and three auxiliary probe columns 2, wherein the rod body 1 is composed of two sub-rods, and the two sub-rods are connected by threads. The side wall of the rod body 1 is axially provided with a wire installation groove 3, and two snap wire buckles 8 are uniformly arranged on the notch of the wire installation groove 3,

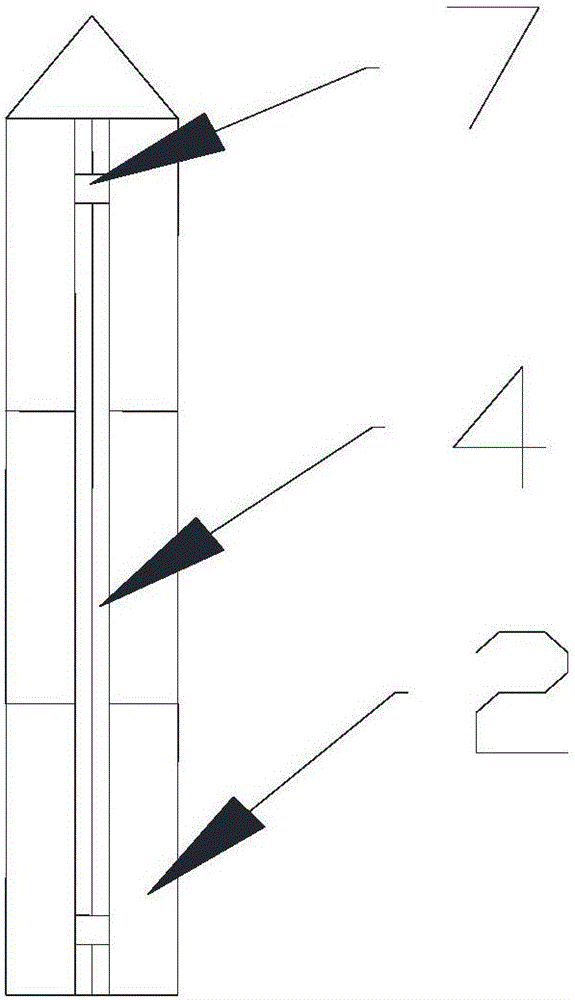

[0023] Among them, the auxiliary probe column 2 is composed of three sub-columns, and the adjacent sub-columns are connected by clamping or threading, and a probe installation groove 4 is axially provided on the side wall of each auxiliary probe column 2, and the probe is installed Buckles 7 are respectively provided on the outer end and inner end of the notch of the groove 4, and the inner end of the auxiliary probe column 2 is vertically connected with the rod body 1 by c...

Embodiment 2

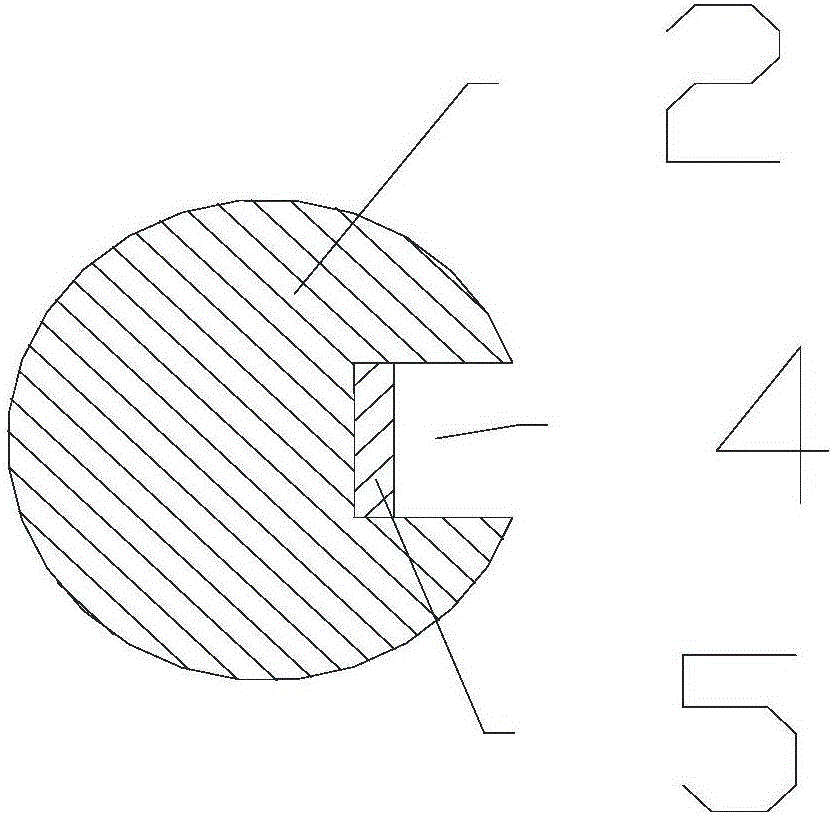

[0024] Embodiment two: if Figure 4 As shown, when other structures are the same as in the first embodiment, as a modification, an adhesive layer 5 is provided at the bottom of the probe installation groove 4, and the adhesive layer 5 is a rubber layer. A cover plate 6 is arranged on the notch of the probe installation groove 4 . It is convenient to arrange the sensor probes, and at the same time, the cover plate 6 can further prevent the sensor probes from being displaced and deformed during the process of arranging and inserting explosives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com