Three-dimensional hierarchical porous carbon film as well as preparation method and application thereof

A carbon film, three-dimensional technology, applied in the field of three-dimensional multi-level porous carbon film and its preparation, can solve the problems of low actual utilization rate and slow material exchange, and achieve the effect of reducing influence and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

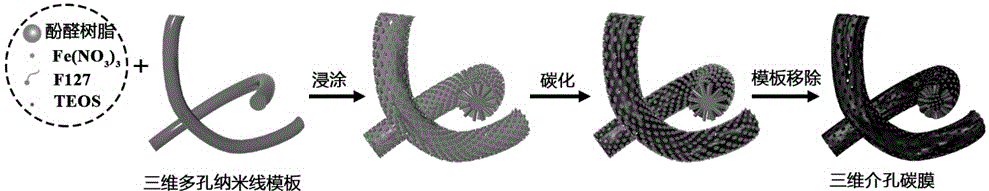

Method used

Image

Examples

Embodiment Construction

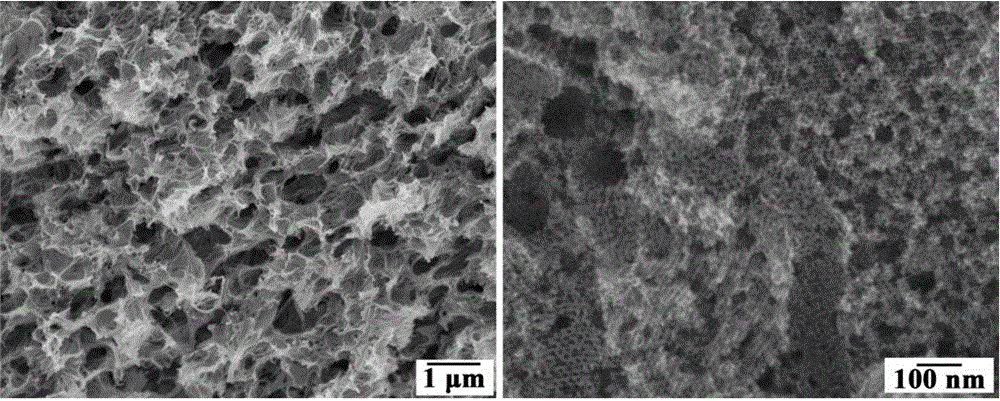

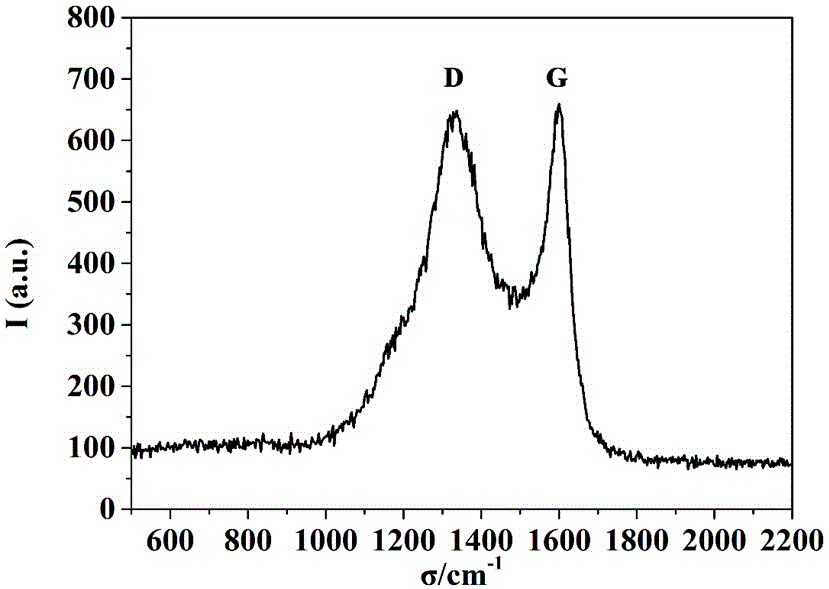

[0028] The present invention will be further described below in conjunction with the accompanying drawings and experimental examples, so that the content described above can be better understood.

[0029] The preparation method of silicon oxide nanowire film:

[0030] The preparation of silicon oxide nanowire film refers to the method of literature [1]. Dissolve 1 g of polyvinylpyrrolidone in 10 g of amyl alcohol, then add 1 g of ethanol, 0.28 g of water, 0.067 mL of 0.18 M sodium citrate, 0.2 mL of ammonia water, shake well and add 0.1 mL of tetraethoxysilane and 0.01 mL of Trimethoxyoctadecylsilane, shake well and let stand overnight. After centrifugation, the product was washed three times with ethanol and water respectively. Then the product is dissolved in ethanol, and suction-filtered on a template with a specific shape to prepare a silicon oxide sheet with a certain shape and thickness. In this patent, the template used is a prototype with a diameter of 4 mm. The th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com