Plant floriculture drying machine and using method

A drying machine, plant flower technology, applied in the drying of plant specimens, drying under negative pressure, in the field of drying equipment for plant specimens, can solve the problems of complex and cumbersome absorption process, no occurrence and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

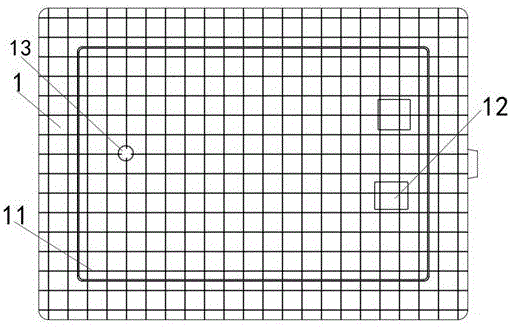

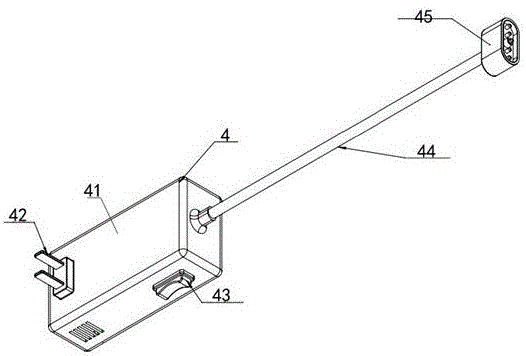

[0023] In order to further illustrate the advantages of the present invention, further description will be made below in conjunction with the accompanying drawings. As shown in the figure, a plant flower drying machine includes a heating device 1, and the heating device 1 is electric heating, and it also includes a The upper cover 3, the upper cover 3 is covered on the heating device 1; the heating device 1 is a heating plate, and a negative pressure air extraction hole 13 is arranged on the heating plate, and the negative pressure air extraction hole 13 passes through the trachea and the outside The negative pressure pump is connected; the processed plant is placed on the heating plate, pressed down with the upper cover 3, and the heating plate is energized and the negative pressure pump power supply 43 is opened to pump air.

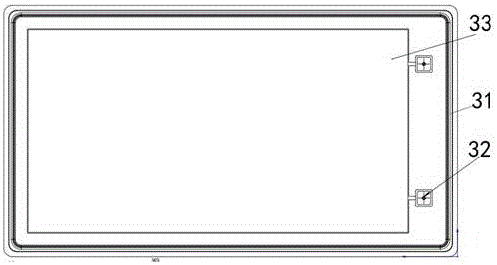

[0024] The upper cover 3 is a flat heating plate; two electrical connection points 32 are arranged on the flat heating plate, and two corresponding hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com