Rubber pipe and preparation method and application thereof

A technology of rubber tubes and fluororubbers, applied in the direction of hoses, pipes, mechanical equipment, etc., to achieve excellent permeability resistance, improve structural integrity, and meet the effects of oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

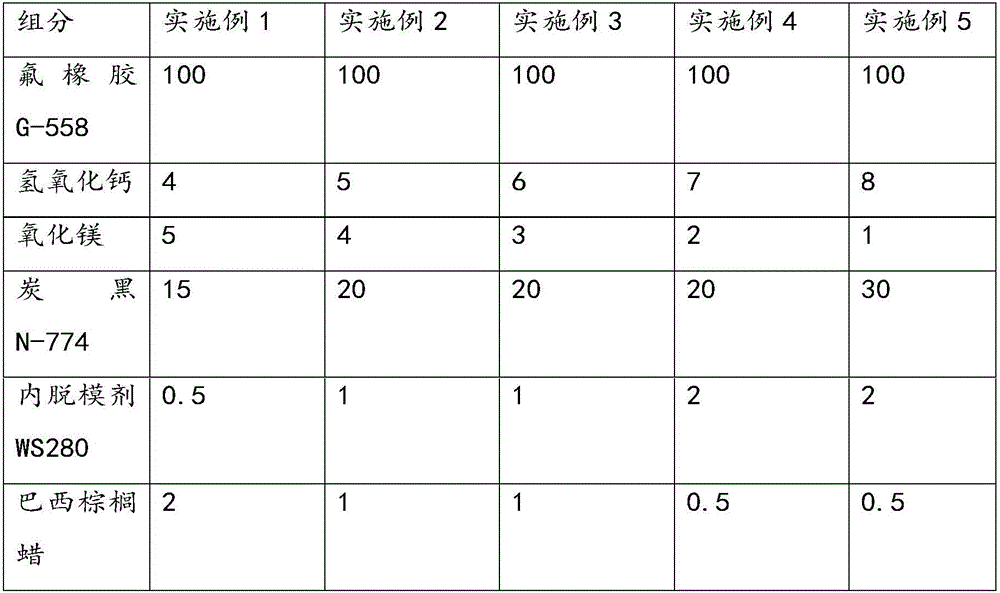

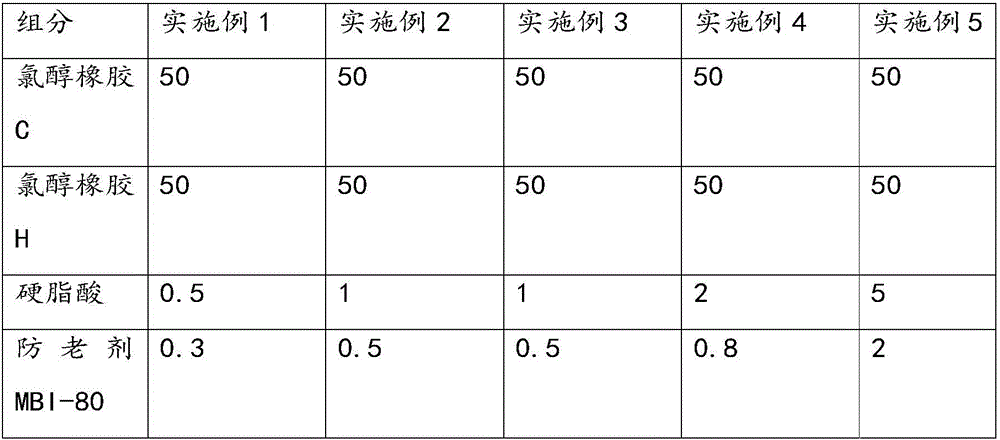

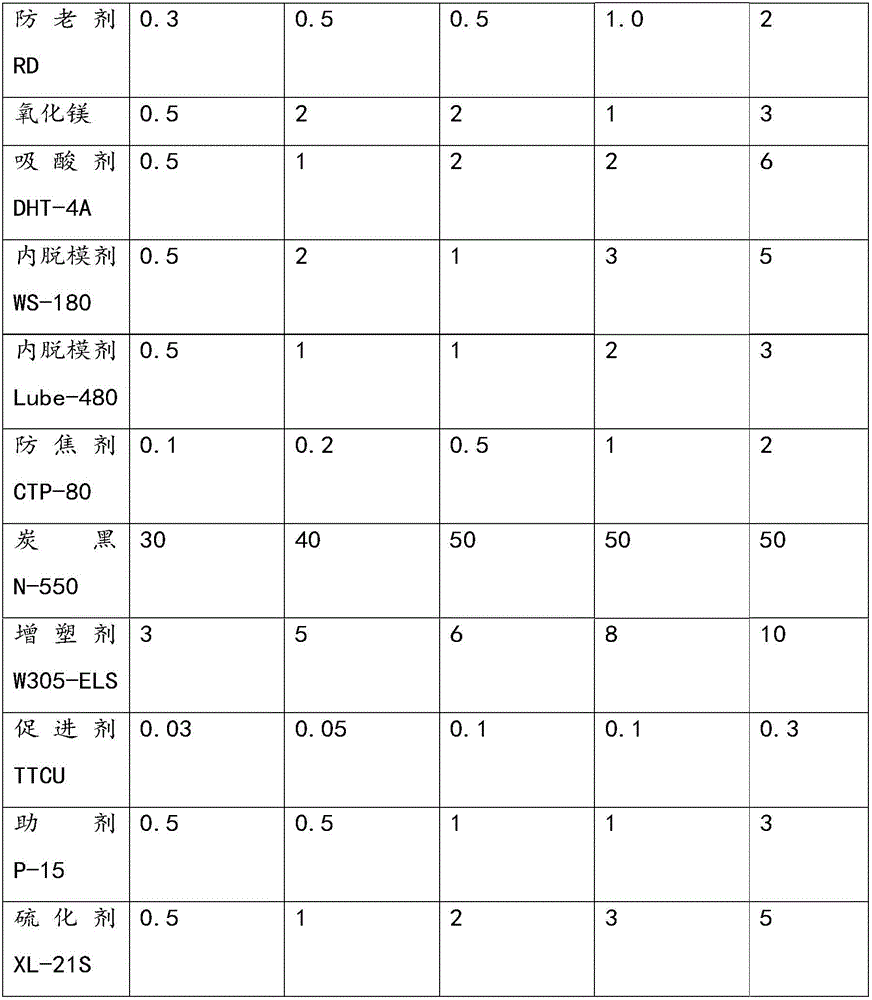

[0103] The rubber tube in the automobile fuel steam pipe assembly uses FKM as the inner layer, fluororesin as the middle layer and ECO as the outer layer, wherein the fluororesin middle layer is Daikin CPT in Japan, and the FKM inner layer and ECO outer layer are according to Table 1 and Table 2 respectively The proportions of the raw materials shown were weighed to obtain the FKM inner layer and ECO outer layer material formulations of Examples 1-5.

[0104] Table 1 Embodiment 1-5FKM inner layer material formula

[0105]

[0106] Table 2 Example 1-5 ECO outer layer material formula

[0107]

[0108]

[0109] Then, prepare the rubber pipe in the automobile fuel vapor pipe assembly according to the following steps:

[0110] (1) Weigh fluororubber G-558, calcium hydroxide, magnesium oxide, carbon black N-774, internal release agent WS280 and carnauba wax according to the formula ratio in Table 1 for mixing, and then introduce them into the extruder Among them, the ext...

Embodiment 6

[0120] Different from Example 1, in the preparation steps of the rubber tube:

[0121] (1) The extrusion temperature of the inner layer FKM is:

[0122] Head temperature: 110°C; extrusion section temperature: 60°C; plasticizing section temperature: 60°C; screw section temperature: 60°C;

[0123] (2) The extrusion temperature of the middle layer CPT is:

[0124] Head temperature: 280°C; extrusion section temperature: 270°C; plasticizing section temperature: 270°C; screw section temperature: 260°C; feeding section temperature: 250°C;

[0125] (3) The extrusion temperature of the outer layer ECO is:

[0126] Head temperature: 110°C; extrusion section temperature: 100°C; plasticizing section temperature: 90°C; screw section temperature: 80°C;

[0127] The primary vulcanization parameters are: vulcanization temperature 155°C, vulcanization time 20min, and the secondary vulcanization parameters are: vulcanization temperature 160°C, vulcanization time 80min.

[0128] All the othe...

Embodiment 7

[0130] Different from Example 1, in the preparation steps of the rubber tube:

[0131] (1) The extrusion temperature of the inner layer FKM is:

[0132] Head temperature: 100°C; extrusion section temperature: 50°C; plasticizing section temperature: 50°C; screw section temperature: 50°C;

[0133] (2) The extrusion temperature of the middle layer CPT is:

[0134] Head temperature: 260°C; extrusion section temperature: 250°C; plasticizing section temperature: 250°C; screw section temperature: 240°C; feeding section temperature: 220°C;

[0135] (3) The extrusion temperature of the outer layer ECO is:

[0136] Head temperature: 100°C; extrusion section temperature: 90°C; plasticizing section temperature: 90°C; screw section temperature: 80°C;

[0137] The primary vulcanization parameters are: vulcanization temperature 165°C, vulcanization time 30min, and the secondary vulcanization parameters are: vulcanization temperature 170°C, vulcanization time 100min.

[0138] All the othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com