A method for realizing hard sealing of elastic shutter assembly device

A technology of hard sealing and assembly, applied in the direction of valve devices, safety valves, functional valves, etc., can solve problems such as hard sealing of mechanisms, and achieve the effects of high reliability, strong stability, and strong process feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

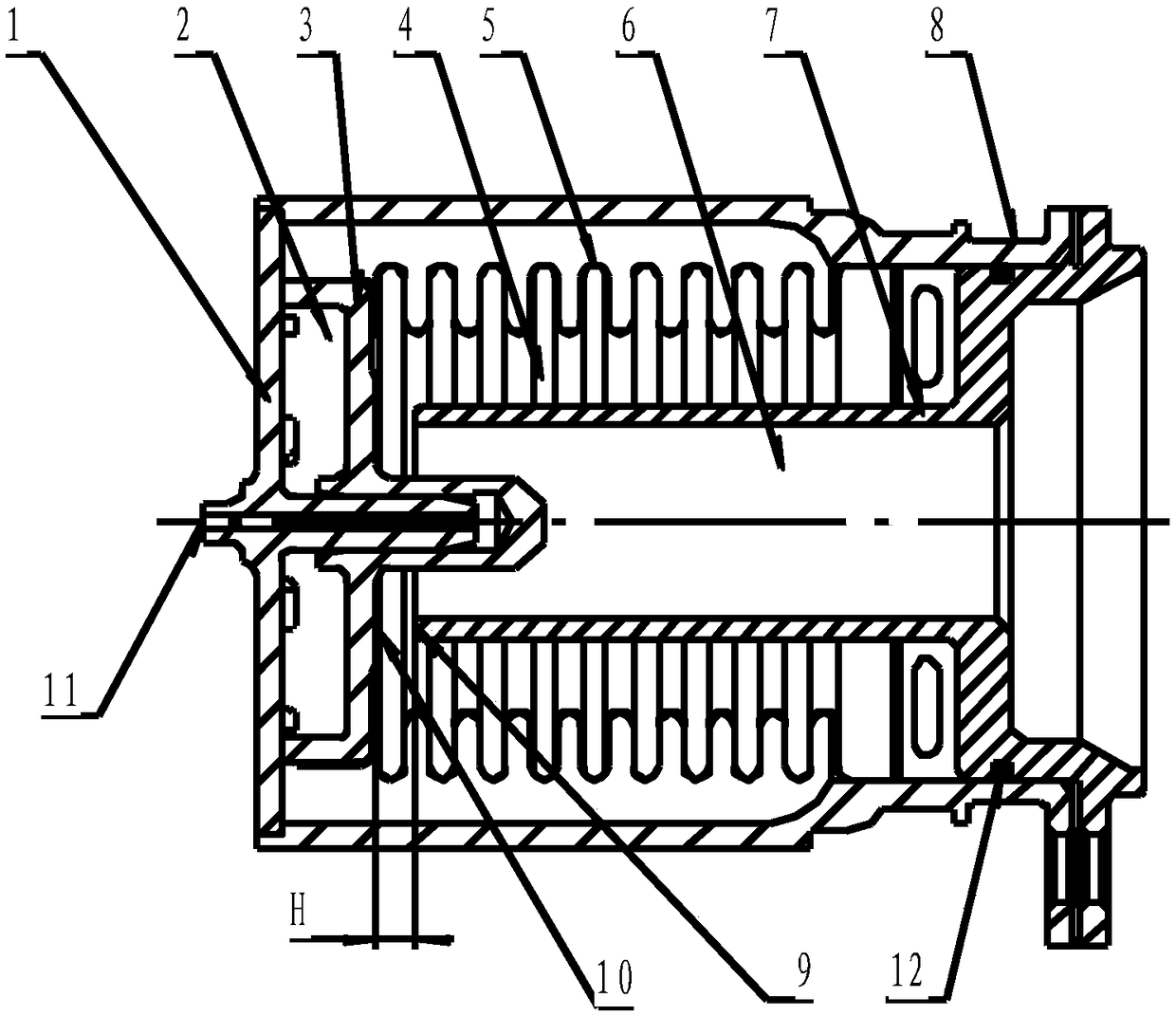

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, please refer to figure 1 .

[0022] Such as figure 1 As shown, it is the applicable object of this method. The elastic valve assembly device includes a housing cover 1, a valve sealing chamber 2, a bellows cover 3, a valve pressure sensing chamber 4, a bellows 5, a working pressure chamber 6, a valve seat 7, Shell 8, seat sealing surface 9, cover sealing surface 10, pressure charging port 11, sealing ring 12, the two ends of the bellows 5 are respectively resistance welded with the bellows cover 3 and the shell 8; the shell 8 and the shell cover 1 are electronically Beam welding; housing cover 1 and the hole shaft of bellows cover 3 are connected by sliding fit; valve seat 7 and housing 8 are assembled and connected by screws, and the two are sealed in the circumferential direction by sealing ring 12, and the sealing surface 9 of the rear seat is assemble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com