Mechanical type separation-and-union device for transmission shafts

A technology of clutch device and drive shaft, which is applied in the direction of transmission parts, mechanically driven clutches, and mutually meshing clutches, etc., can solve problems such as oil leakage or noise pollution, malfunction, slipping, etc., and achieve short adjustment time, easy operation, Clutch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the purpose, structure and function of the present invention, a mechanical clutch device for a transmission shaft of the present invention will be further described in detail below in conjunction with the accompanying drawings.

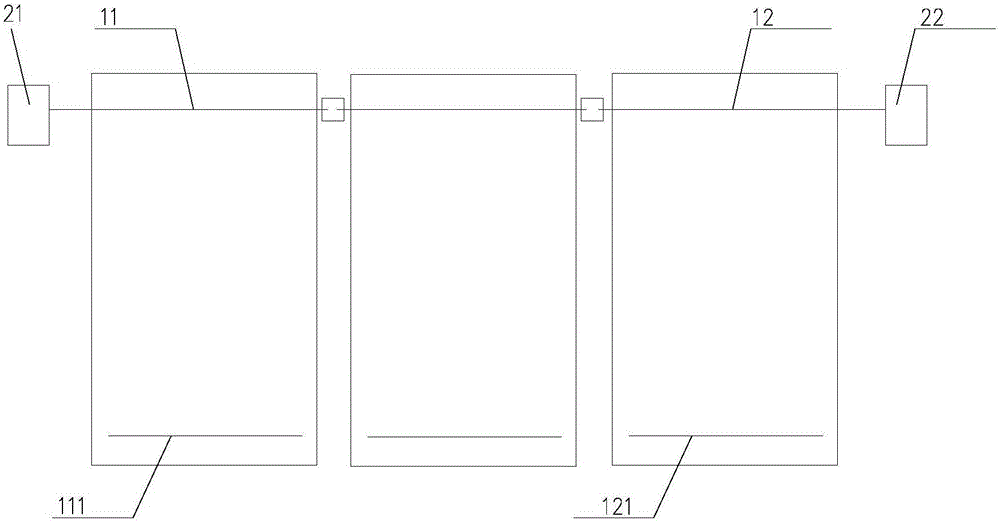

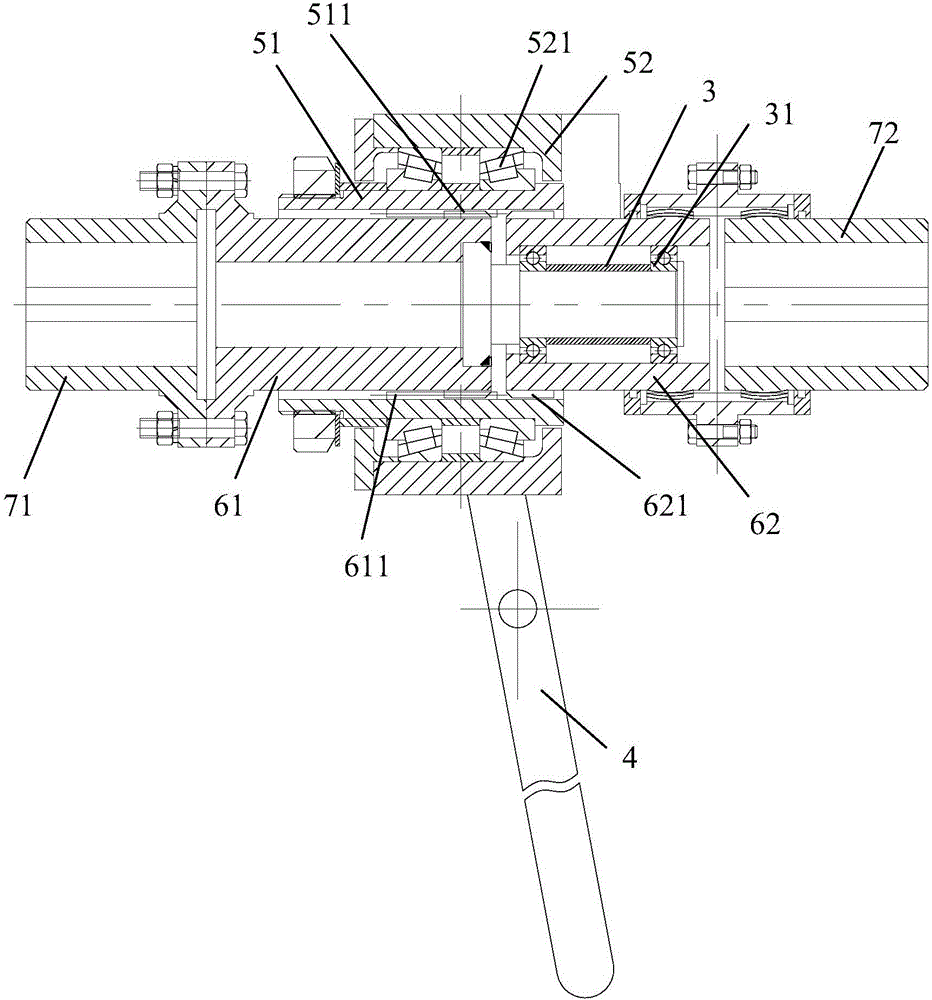

[0026] Such as figure 1 and figure 2 As shown, it is shown as a mechanical clutch device of a transmission shaft of the present invention, which is used to connect and separate the transmission shafts in multiple groups of transmission platforms (movable platforms or horizontal transport equipment), specifically, on the transmission platform Both sides are provided with transmission shafts, and both sides of the transmission platform are provided with a first power source 21 and a second power source 22 for transmitting power. The shafts are connected together, and the power is transmitted through the transmission shaft to the transmission platform to drive the transmission platform to move synchronously. A clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com