Oil pipe gas injection and water drainage technique and tools thereof

A technology of gas injection, drainage and oil pipe, which is applied in drilling pipe, casing, production fluid, etc., can solve the problems of low pressure bearing capacity, low recovery rate, no self-testing and sealing, etc. Guarantee the effect of normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

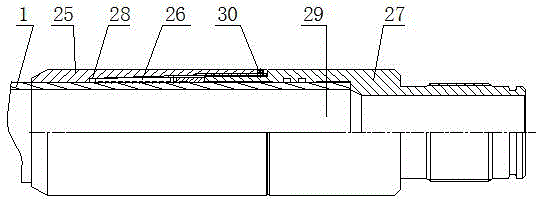

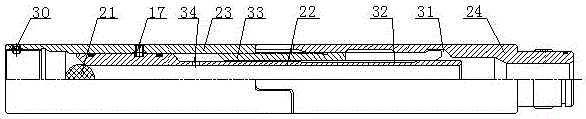

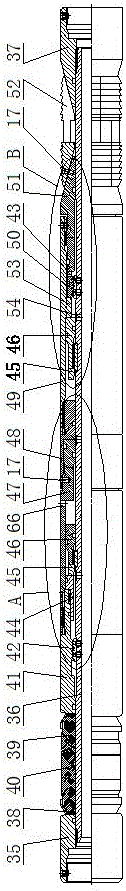

[0056] In the present invention, the wellbore that requires gas injection and drainage is composed of casing 20, oil pipe 13 and casing packer 5; casing 20 is inserted with oil pipe 13; device 5. Casing packer 5 can completely seal the annulus between tubing 13 and casing 20; upper perforation 14 is set on tubing 13 above casing packer 5; upper perforation 14 is set on tubing 13 below casing packer 5; There are 15 lower perforations.

[0057] The specific steps of the tubing gas injection and drainage process are as follows:

[0058] The first step, entering the well string:

[0059] According to the production requirements, connect the coiled tubing 1 with the slip connector 2, the safety joint 3, the hydraulic hanger 4, the slip connector 2, the coiled tubing 6, the slip connector 2, the isolation packer 8, and the pressing plug 9 , plug 10, screen pipe 11 and round head guide shoe 12 are sequentially connected to form a pipe string.

[0060] Between slip connector 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com