Cock type ball casting device for oil drilling

A ball-throwing device, oil drilling technology, applied in wellbore/well valve device, earth-moving drilling, wellbore/well components, etc., can solve the problems of time-consuming and laborious, high-altitude operation, sticking, etc., to achieve convenient operation and flexible use , The effect of saving drilling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

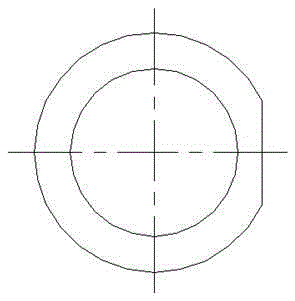

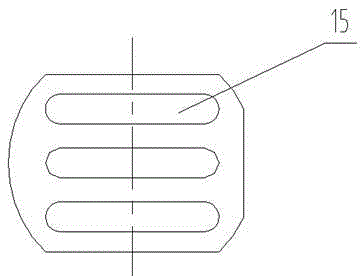

[0016] refer to figure 1 , a cock type oil drilling device comprising a body 1, a retaining spring 2, a four-open ring 3, an upper valve seat seal ring 4, an upper valve seat 5, a lower four-open ring 6, a cock switch 7, and a cock switch seal ring 8 , Lower valve seat 9, wave spring 10, upper block 11, steel ball 12, cage ball valve 13 and lower valve seat sealing ring 14.

[0017] refer to figure 1 , The lower valve seat 9 is installed in the lower part of the inner cavity of the body 1, and the wave spring 10 is located in the lower part of the lower valve seat 9 to play a shock absorbing role. The caged ball valve 13 is located at the upper end of the lower valve seat 9, and the side is connected with the cock switch 7 through a square hole. The lower four open rings 6 are located on the cage ball valve 13 and are stuck inside the body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com