Magnetic force automatic dedusting window frame

An automatic dust removal and window frame technology, applied in the cleaning of window/door frame, window/door, window, etc., can solve the problems of poor window opening and closing, cumbersome operation, and low cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

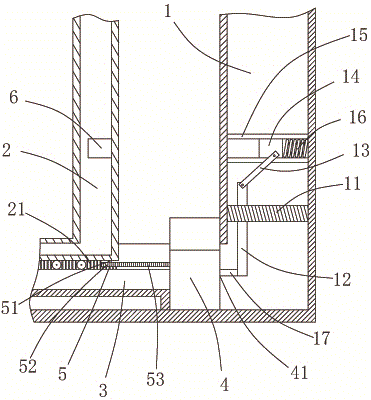

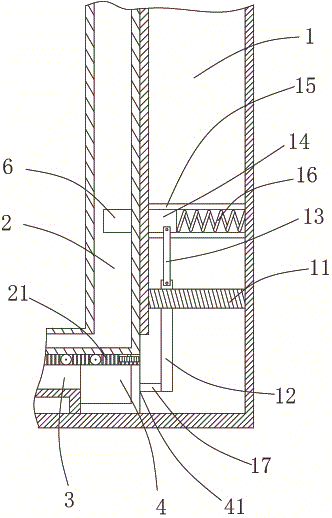

[0008] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 2 , magnetic automatic dust removal window frame, including a window frame 1 and a window 2, a slide rail 3 is provided at the bottom of the window frame 1, a brush 21 is provided at the bottom of the window 2, and a dust storage box 4 is provided at both ends of the slide rail 3 , the dust storage box 4 is rotatably connected with the window frame 1, the window frame 1 is provided with a fixed block 11, the fixed block 11 is pierced with a bending rod 12, and the upper end of the bending rod 12 rotates A connecting rod 13 is provided, and the connecting rod 13 is rotatably connected with an iron slider 14, and the slider 14 is slidably arranged on a slideway 15 located in the window frame 1, and the slider 14 and the slider A spring 16 is provided between the ends of the road 15, a bending part 17 is provided at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com