Method for regulating and controlling homogenization degree of polyacrylonitrile preoxidized fiber

A technology of polyacrylonitrile fiber and pre-oxidized fiber, which is applied in fiber processing, textile and papermaking, etc., can solve the problems of affecting the modification effect, demulsification of oil agent, affecting the oiling effect of raw silk, etc., so as to improve the homogenization degree, the effect of improving the modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

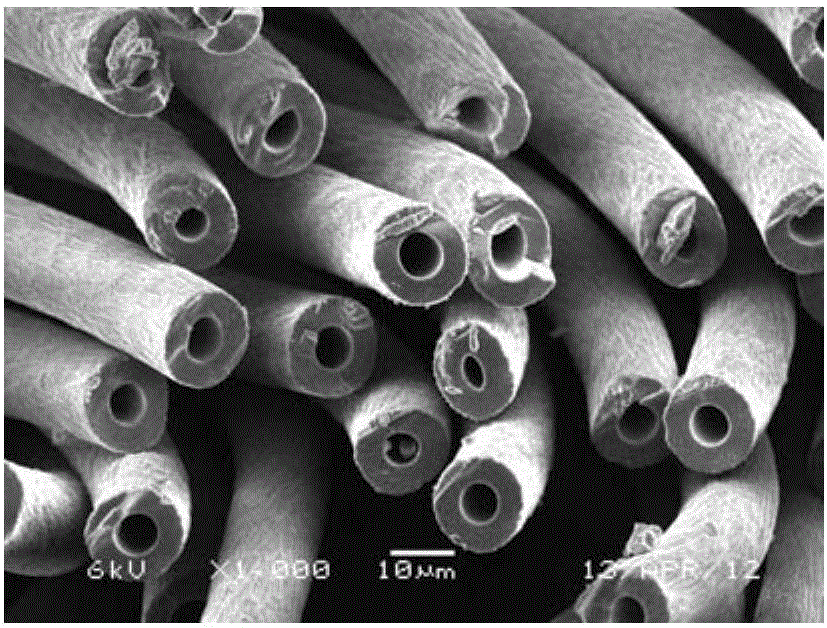

[0031] At room temperature, impregnate 2g of 1KPAN fiber in an Erlenmeyer flask filled with 200ml of xylene, then place the Erlenmeyer flask in an ultrasonic oscillator of the model YH-320DH for 5 minutes, and use ultrasonic vibration to increase The removal efficiency and effect of PAN fiber surface oil agent. After removing the PAN fiber surface oil agent, the PAN fiber with the surface oil agent removed is immersed in a boric acid solution with a mass fraction of 0.5% for 1 min, and the temperature is raised from room temperature to 260 °C at a heating rate of 9 °C / min, and then heated at 260 °C. Stay for 30min. Weigh 1g of the resulting pre-oxidized fiber, cut it into 3cm short filaments, dip it in a flask filled with sulfuric acid solution, the sulfuric acid solution concentration is 40wt%, the sulfuric acid solution is heated to boiling, and treated under boiling conditions for 0.8h, then use Stir and wash with deionized water until neutral, filter through filter paper,...

Embodiment 2

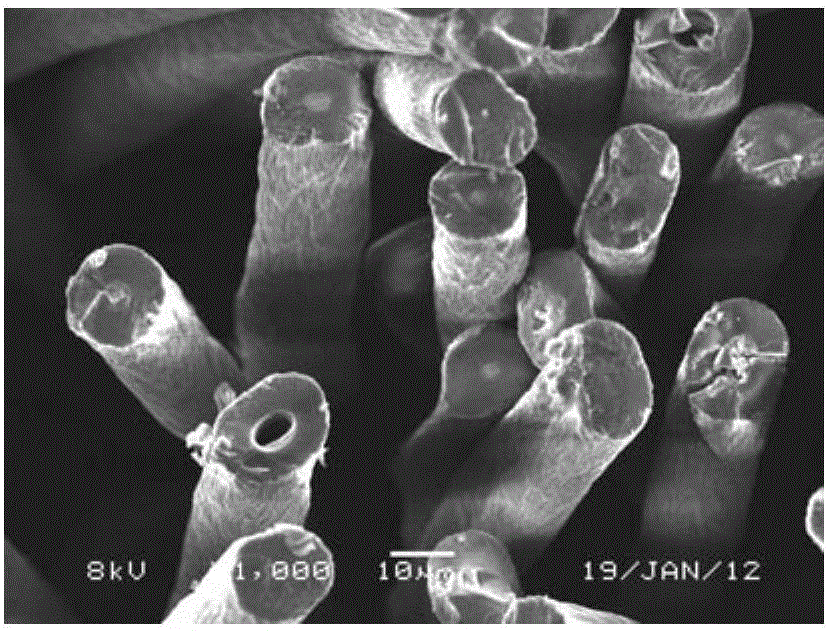

[0035] At room temperature, impregnate 2g of 3KPAN fiber in a conical flask filled with 200ml of xylene, then place the conical flask in an ultrasonic oscillator of the model YH-320DH for 8 minutes, and use ultrasonic vibration to increase The removal efficiency and effect of PAN fiber surface oil agent. After removing the PAN fiber surface oil agent, the PAN fiber with the surface oil agent removed is immersed in a boric acid solution with a mass fraction of 1% for 2 minutes, and the temperature is raised from room temperature to 280°C at a heating rate of 8°C / min, and then heated at 280°C. Stay for 25min. Take by weighing 1g of the gained preoxidized fiber, cut it into 3cm long short filaments, adopt the same treatment and sample preparation method as in Example 1, scan the preoxidized fiber cross-section with SEM, as shown in the attached Figure 4 shown.

Embodiment 3

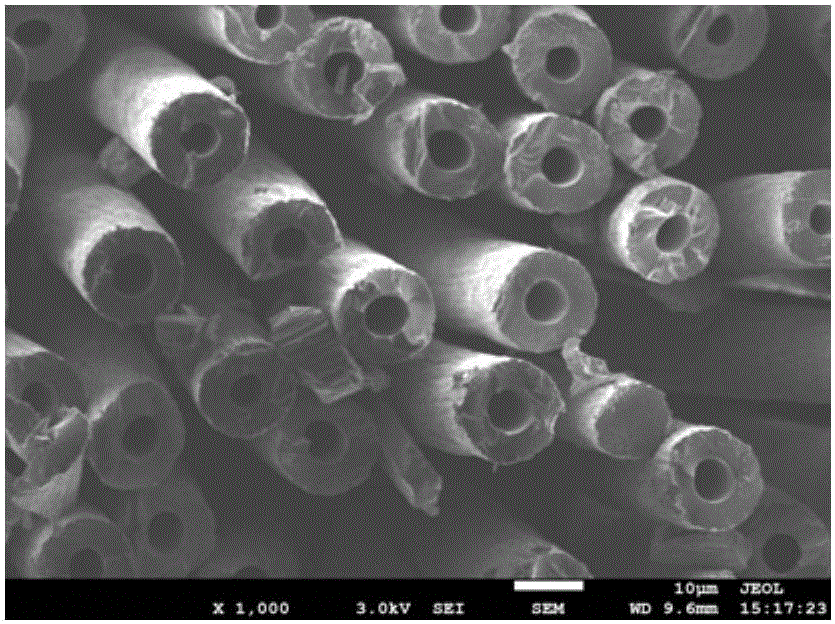

[0039] At room temperature, impregnate 6KPAN fibers with a weight of 2g in an Erlenmeyer flask containing 200ml of xylene, and then place the Erlenmeyer flask in an ultrasonic oscillator of the model YH-320DH for 10 minutes, and use ultrasonic vibration to increase The removal efficiency and effect of PAN fiber surface oil agent. After removing the PAN fiber surface oil agent, the PAN fiber with the surface oil agent removed is immersed in a boric acid solution with a mass fraction of 2% for 3 minutes, and the temperature is raised from room temperature to 300°C at a heating rate of 7°C / min, and then heated at 300°C. Stay for 20min. Take by weighing 1g of the gained preoxidized fiber, cut it into 3cm long short filaments, adopt the same treatment and sample preparation method as in Example 1, scan the preoxidized fiber cross-section with SEM, as shown in the attached Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com