Coaxial powder feeding sprayer capable of automatically adjusting light spots and powder feeding positions

An automatic adjustment, coaxial powder feeding technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of reducing processing efficiency, affecting the surface quality of processed parts, structural size differences, etc., to improve the utilization rate and ensure convergence. The effect of stability and stability, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

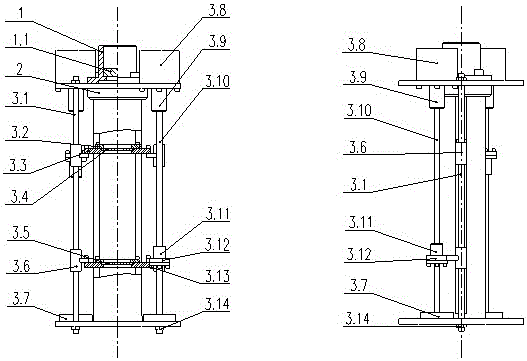

[0033] The present invention will be further described below in conjunction with accompanying drawing.

[0034] It should be noted that the relative arrangement, numerical values, etc. of components set forth in the present embodiment are not limited to the scope of the present invention unless specifically stated otherwise. As preferably, in this specific embodiment, the powder spray pipe 4.17 quantity is selected as four, and its special quantity is all within the scope of protection of the present invention as long as it can form a complete annular powder curtain in the powder spray process, and the quantity is not limited. Specific restrictions; the number of corresponding connecting ears 5.2 and four-bar linkage mechanism is designed to be four, corresponding to the number of powder spraying pipes 4.17; preferably, the number of air inlets 5.1 for shielding gas is designed to be three.

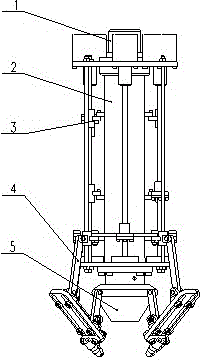

[0035] Such as figure 1 As shown, a coaxial powder feeding nozzle that can automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com