Energy-saving and water-saving yellow wine production device

A kind of production equipment and equipment technology, applied in the fields of wine making and food processing, can solve the problems that affect the development of rice wine industry, increase the production cost and the difficulty of environmental governance, etc., and achieve the advantages of easy cleaning and maintenance, shortening the soaking time of rice, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

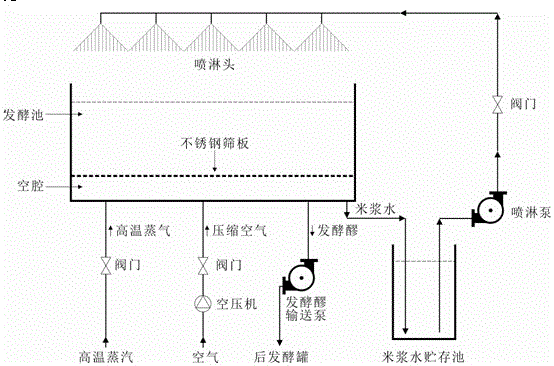

[0022] Such as figure 1 As shown, the above-mentioned device takes the size of 800cm long, 244cm wide and 122cm high as an example, and with 5000kg rice as raw material, the process steps of producing yellow rice wine are as follows:

[0023] 1. Rice delivery: Use wind conveyor to input 5000kg of raw rice into the trough and smooth it out.

[0024] 2. Rice soaking: Put 2500L of clean water in the spray storage tank, turn on the spray device, and spray evenly from top to bottom. Depending on the temperature, spray for 2-4 hours until the rice grains no longer absorb water.

[0025] 3. Loose rice: After the rice soaking operation is completed, open the compressed air valve and use high-pressure air to loosen the rice.

[0026] 4. Drainage: Open the valve at the bottom, drain the rice milk water into a special stainless steel tank containing rice milk water for clarification. Drain the pulp water, and the rice pulp water is about 1000L.

[0027] 5. Steam rice: open the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com