Weather-proof film for plastic floor

A technology of plastic flooring and weather-resistant film, which is applied in applications, adhesives, household appliances, etc. It can solve the problems of inconvenient maintenance, easy staining and leaving traces of chemical reagents, and limit the application range of plastic flooring, so as to achieve improved wear resistance, Good protection, excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

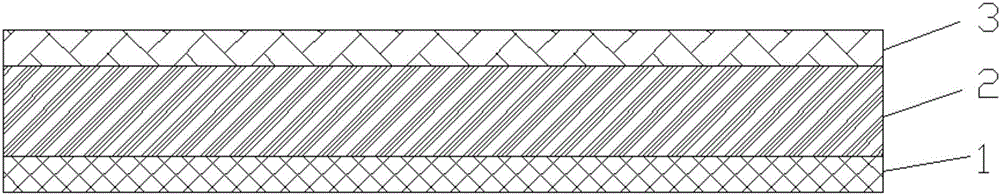

[0024] Depend on figure 1 As shown, a weather-resistant film for plastic flooring in this embodiment is formed by co-extrusion of an outer protective layer 1, a functional layer 2 and an adhesive layer 3 with a thickness ratio of 1:3:1. The outer protective layer 1 is fluorine-containing The high polymer polyvinylidene fluoride and polytetrafluoroethylene are mixed in a ratio of 100:3, and the functional layer 2 is a mixture of polyvinylidene fluoride, polyacrylic resin and functional additives in a ratio of 60:30:10.5. The functional additive is made by mixing UV absorber and toughening agent at a ratio of 0.5:10, and the adhesive layer 3 is made of fluorine-containing high polymer polyvinylidene fluoride and modified polyacrylic resin at a ratio of 60:40. The proportion is mixed; the weather-resistant film for plastic flooring of this embodiment can be connected with the polyvinyl chloride floor layer by hot-melt bonding through the adhesive layer 3.

Embodiment 2

[0026] Depend on figure 1 As shown, a weather-resistant film for plastic flooring in this embodiment is formed by co-extrusion of an outer protective layer 1, a functional layer 2 and an adhesive layer 3 with a thickness ratio of 1:3:1. The outer protective layer 1 is fluorine-containing The high polymer polyvinylidene fluoride and polytetrafluoroethylene are mixed in a ratio of 100:10, and the functional layer 2 is a mixture of polyvinylidene fluoride, polyacrylic resin and functional additives in a ratio of 80:20:1. The functional auxiliary agent is formed by mixing antioxidant and toughening agent in a ratio of 0.5:0.5, and the bonding layer 3 is polyethylene-vinyl acetate resin; the weather-resistant film for plastic flooring in this embodiment can be bonded Layer 3 is hot melt bonded to the polypropylene floor layer.

Embodiment 3

[0028] Depend on figure 1 As shown, a weather-resistant film for plastic flooring in this embodiment is formed by co-extrusion of an outer protective layer 1, a functional layer 2 and an adhesive layer 3 with a thickness ratio of 1:3:1. The outer protective layer 1 is fluorine-containing High polymer polyvinylidene fluoride, the functional layer 2 is made of polyvinylidene fluoride and functional additives in a ratio of 90:10, and the functional additives are UV absorbers and tougheners in a ratio of 2:8 The adhesive layer 3 is formed by mixing polyvinylidene fluoride and polyvinyl butyral resin in a ratio of 10:90; the weather-resistant film for plastic flooring in this embodiment can be bonded to the polyethylene floor through the adhesive layer 3 The layers are connected by hot melt bonding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com