High-efficiency leveling latex paint and preparation method thereof

A latex paint and leveling technology, applied in latex paint, coating, etc., can solve the problems of inconvenient maintenance due to physical injury of construction personnel, dependence on the spraying level of construction personnel, and heavy workload of shielding, so as to achieve good decoration and beautification effect, protect And decorative beautification effect, good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

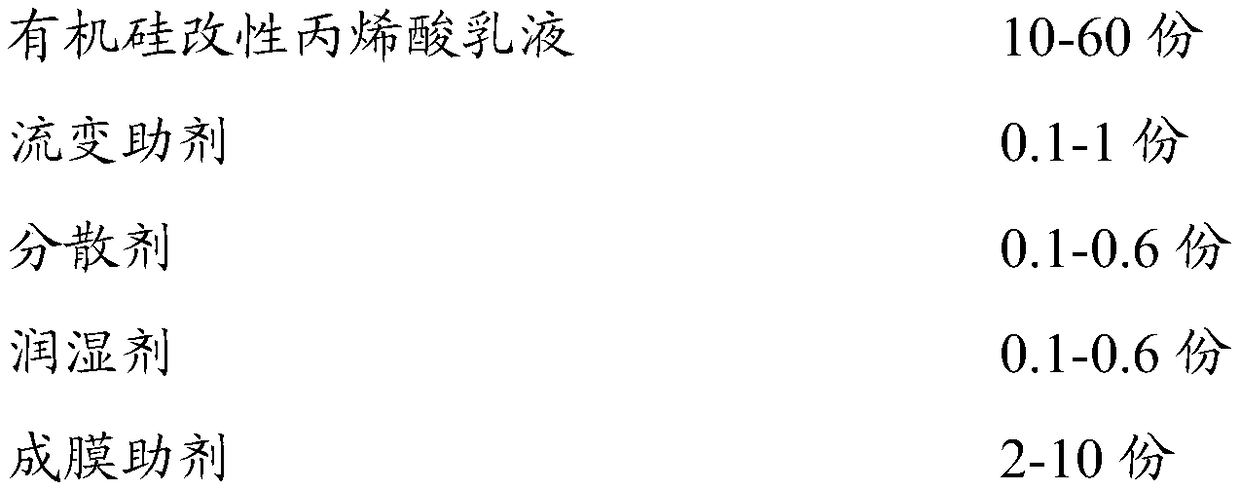

[0043] A kind of high-efficiency leveling latex paint of the present embodiment comprises the following raw material components in parts by weight:

[0044]

[0045]

[0046] The preparation method of above-mentioned emulsion paint comprises the steps:

[0047] Mix water and wetting agent thoroughly for 5 minutes;

[0048] Then add dispersant, defoamer, film-forming aid, and pH regulator in sequence, and mix and stir for 10 minutes;

[0049] Then add pigments and fillers to disperse for 20 minutes until the fineness is ≤60μm.

[0050] Finally, add preservatives, antifungal agents, antifreeze agents, silicone-modified acrylic emulsions, rheological additives 1 and 2 in sequence, and stir for 15 minutes;

[0051] After passing the quality inspection, filter and pack.

Embodiment 2

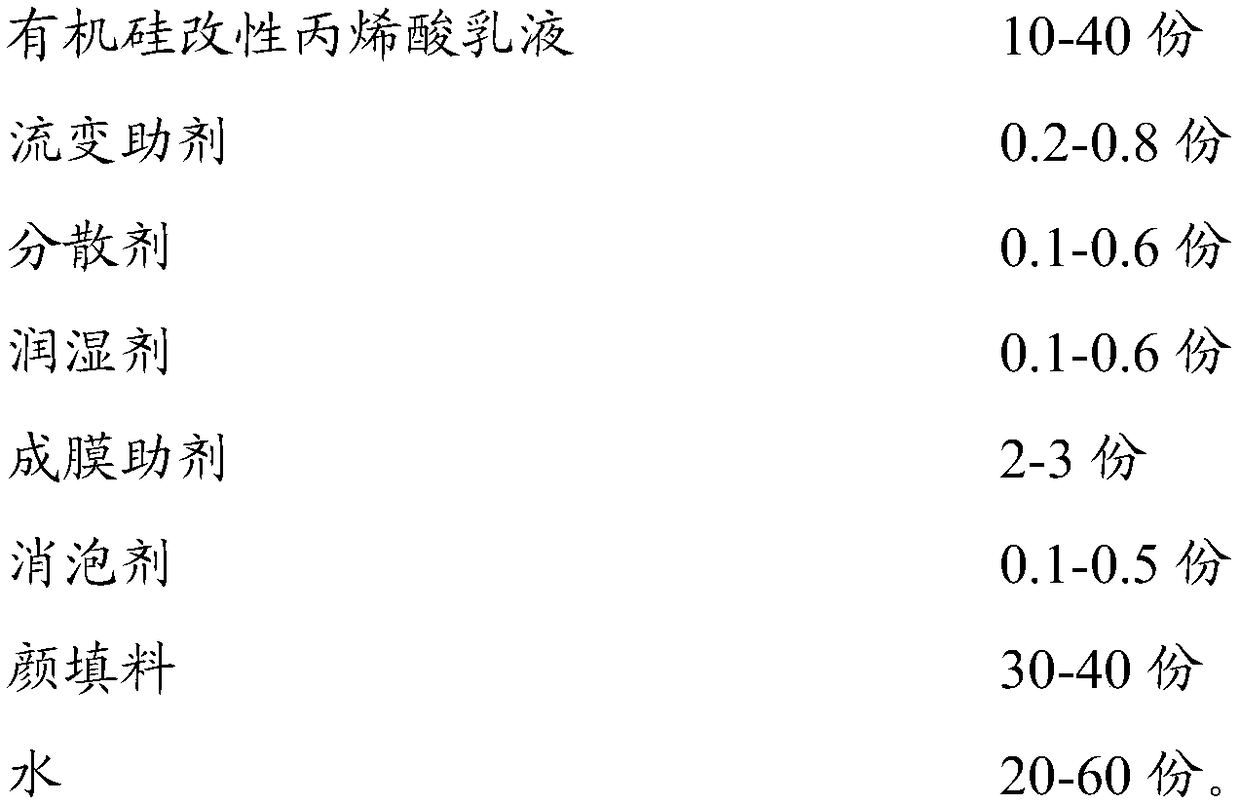

[0053] A kind of high-efficiency leveling latex paint of the present embodiment comprises the following raw material components in parts by weight:

[0054]

[0055]

[0056] The preparation method of above-mentioned emulsion paint comprises the steps:

[0057] Mix water and wetting agent thoroughly for 8 minutes;

[0058] Then add dispersant, defoamer, film-forming aid, and pH regulator in sequence, and mix and stir for 8 minutes;

[0059] Then add pigments and fillers to disperse for 17 minutes until the fineness is ≤60μm.

[0060] Finally, add preservatives, antifungal agents, antifreeze agents, silicone-modified acrylic emulsions, rheological additives 1 and 2 in sequence, and stir for 12 minutes;

[0061] After passing the quality inspection, filter and pack.

Embodiment 3

[0063] A kind of high-efficiency leveling latex paint of the present embodiment comprises the following raw material components in parts by weight:

[0064]

[0065] The preparation method of above-mentioned emulsion paint comprises the steps:

[0066] Mix water and wetting agent thoroughly for 10 minutes;

[0067] Then add dispersant, defoamer, film-forming aid, and pH regulator in sequence, and mix and stir for 5 minutes;

[0068] Then add pigments and fillers to disperse for 15 minutes until the fineness is ≤60μm.

[0069] Finally, add preservatives, antifungal agents, antifreeze agents, silicone-modified acrylic emulsions, rheological additives 1 and 2 in sequence, and stir for 10 minutes;

[0070] After passing the quality inspection, filter and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com