Water-borne wood coating

A wood coating, water-based technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as the inability to achieve a better three-dimensional effect, artistic texture, etc., and achieve excellent adhesion, pleasant vision, Strong stereoscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

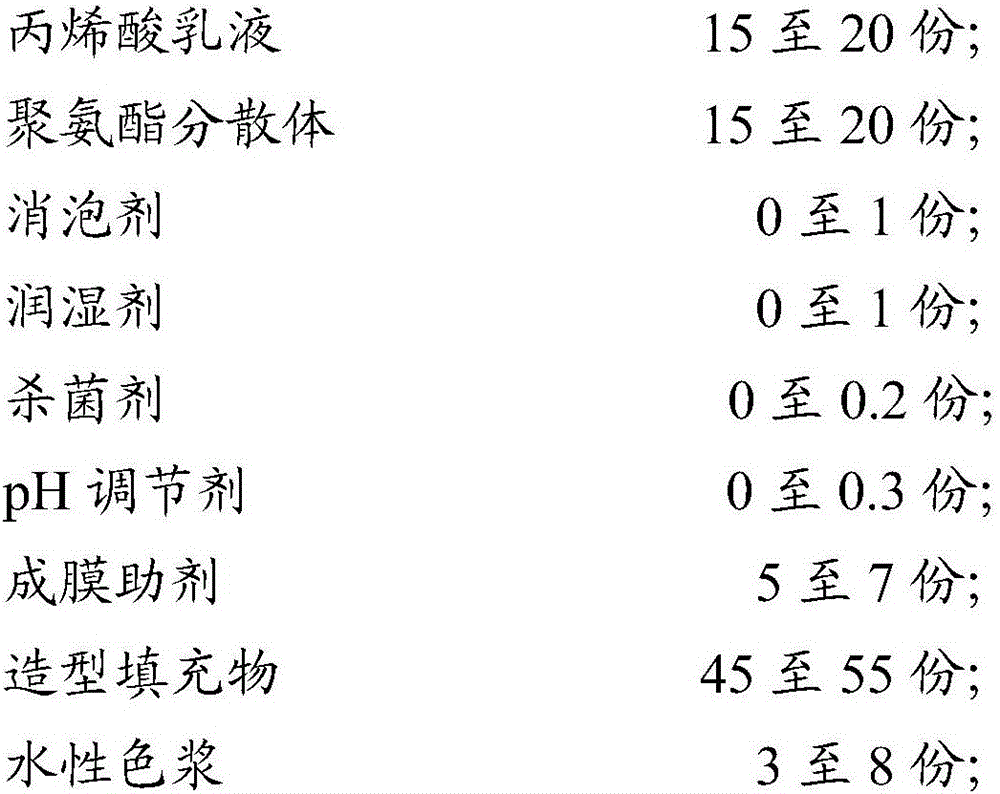

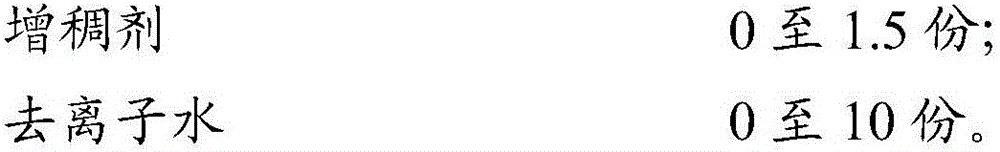

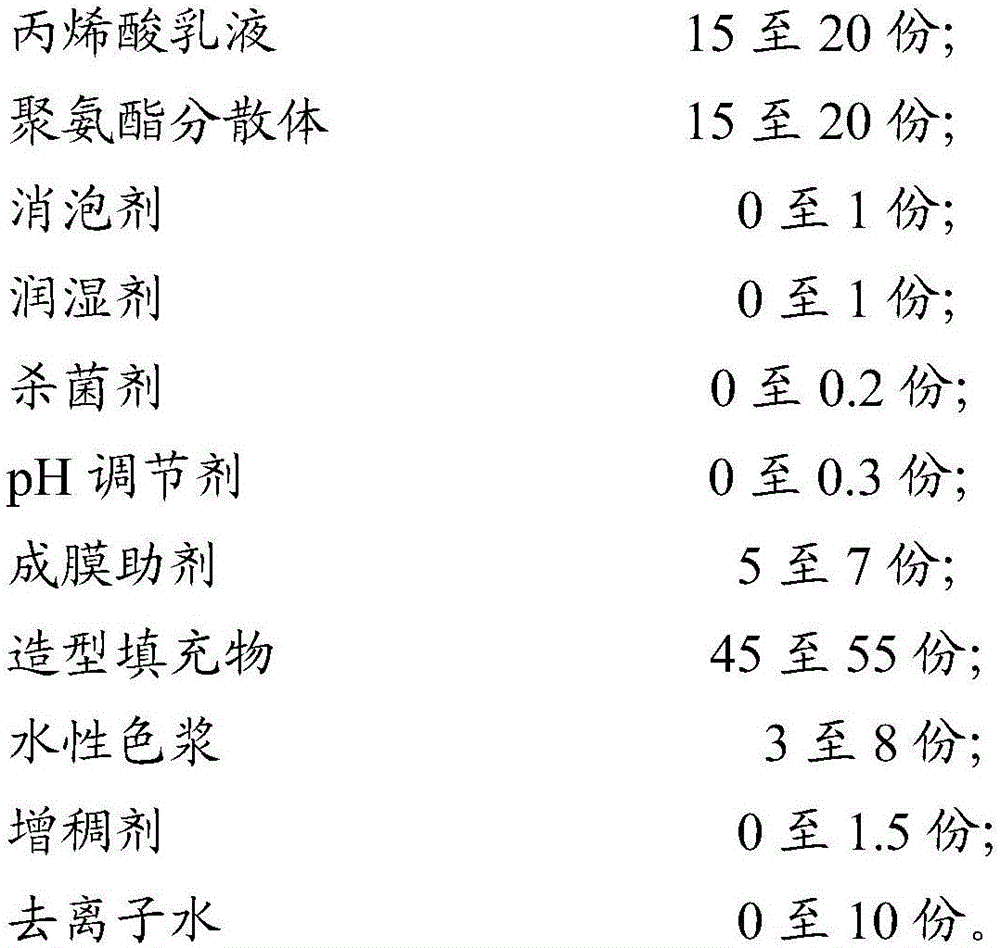

[0041] Prepare materials: 15 parts by weight of modified acrylic emulsion, 15 parts by weight of polyurethane dispersion, 0.5 parts by weight of defoamer, 0.5 parts by weight of wetting agent, 0.1 part by weight of bactericide, 0.2 parts by weight of pH regulator, The film-forming aid of 7 parts by weight, the modeling filler of 54 parts by weight, the water-based colorant of 5 parts by weight, the thickener of 1.2 parts by weight, the deionized water of 1.5 parts by weight,

[0042] After the formula ratio of the above parts by weight is made into a water-based wood coating according to the preparation method provided above, it can be compared with the performance of the solvent-based sand surface effect paint on audio wood furniture, such as the production of audio manufacturers such as Ouke Audio and Yida Audio. For wooden furniture, the sequence of the corresponding construction process can be: material grinding, primer, dry grinding, primer, dry grinding, water-based wood ...

Embodiment 2

[0047] Materials: 19 parts by weight of acrylic emulsion, 19 parts by weight of polyurethane dispersion, 0.5 parts by weight of defoamer, 0.5 parts by weight of wetting agent, 0.1 parts by weight of bactericide, 0.2 parts by weight of pH regulator, 7 parts by weight Parts of film-forming aid, 46 parts by weight of modeling filler, 5 parts by weight of water-based color paste, 1.2 parts by weight of thickener, and 1.5 parts by weight of deionized water.

[0048] After making water-based wood coatings from the above formula by weight according to the preparation method provided above, it can also be used for performance comparison with solvent-based sand surface effect paint on audio wood furniture. The corresponding construction process sequence and construction effect are the same as those in the examples The content described in 1 is the same and will not be repeated here.

[0049] Further, the water-based wood coating in this embodiment can also be tested according to the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com