Synthesis method of reactive hindered phenol oxidation-resistant polyolefin additive and application thereof

A synthesis method and technology of olefin auxiliary agent are applied in the synthesis field of reactive hindered phenol antioxidant polyolefin auxiliary agent, which can solve the problems of poor compatibility of polyolefin polymer, inability of large molecular weight antioxidant to migrate in time, Unfavorable problems such as wide application in industrial production, to achieve long-lasting antioxidant effect, high yield, and non-volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, a synthetic method of a reactive hindered phenol antioxidant polyolefin additive comprises the following steps:

[0026] 1. Take 100 ml of analytically pure acetone, add 5 mol of anhydrous potassium hydroxide and 5 mol of 2,4 dihydroxybenzophenone, keep stirring at room temperature for 4 hours to carry out the reaction, and then keep the temperature at 40°C.

[0027] 2. Slowly drop 5 mol of allyl bromide in acetone solution into the above solution (dropping time is 30 minutes), and continue to react at 40° C. for 2 hours after the dropping is completed.

[0028] 3. Cool the reaction solution to room temperature, filter to remove impurities, and distill under reduced pressure to obtain a crude product. Finally, a solid (2-hydroxy-4-allyloxy-benzophenone) was obtained after recrystallization with 50% ethanol aqueous solution.

[0029] 4. The purity of the solid was 94% as detected by GC, and the yield was 86%. The solvent in the filtrate can be disti...

Embodiment 2

[0031] In this embodiment, a synthetic method of a reactive hindered phenol antioxidant polyolefin additive comprises the following steps:

[0032] 1. Take 100 ml of analytically pure acetone, add 5 mol of anhydrous potassium hydroxide and 5 mol of 2,4 dihydroxybenzophenone, keep stirring at room temperature for 4 hours to carry out the reaction, and then keep the temperature at 40°C.

[0033] 2. Slowly drop 5 mol of allyl bromide in acetone solution into the above solution, and continue to react at 40°C for 6 hours after the drop is completed.

[0034] 3. Cool the reaction solution to room temperature, filter to remove impurities, and distill under reduced pressure to obtain a crude product. Finally, a solid (2-hydroxy-4-allyloxy-benzophenone) was obtained after recrystallization with 50% ethanol aqueous solution.

[0035] 4. The purity of the solid is 97% as detected by GC, and the yield is 97%. The solvent in the filtrate can be distilled and reused.

Embodiment 3

[0037] In this embodiment, a synthetic method of a reactive hindered phenol antioxidant polyolefin additive comprises the following steps:

[0038] 1. Take 100 ml of analytically pure acetone, add 5 mol of anhydrous potassium hydroxide and 5 mol of 2,4 dihydroxybenzophenone, keep stirring at room temperature for 4 hours to carry out the reaction, and then keep the temperature at 50°C.

[0039] 2. Slowly drop 5 mol of allyl bromide in acetone solution into the above solution, and continue to react at 50°C for 6 hours after the drop is completed.

[0040] 3. Cool the reaction solution to room temperature, filter to remove impurities, and distill under reduced pressure to obtain a crude product. Finally, a solid (2-hydroxy-4-allyloxy-benzophenone) was obtained after recrystallization with 50% ethanol aqueous solution.

[0041] 4. The purity of the solid was 97% as detected by GC, and the yield was 93%. The solvent in the filtrate can be distilled and reused.

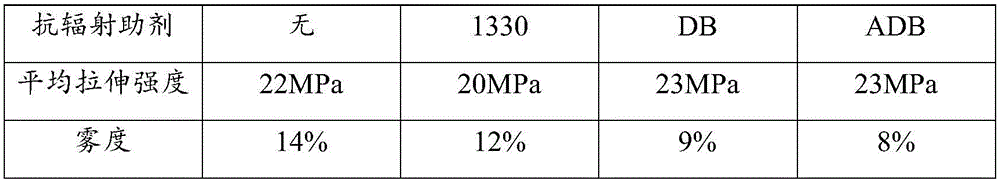

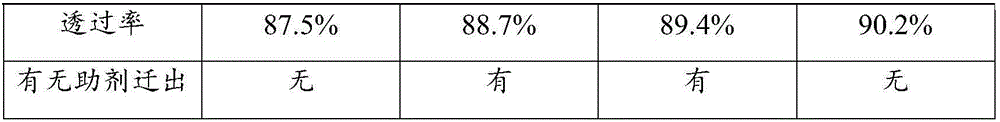

[0042] The react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com