Catalyst system for olefin polymerization, and application of catalyst system

A catalyst and ethylene polymerization technology, applied in the production of bulk chemicals, etc., can solve the problem that the catalyst is not sensitive enough to hydrogen, and achieve the effects of broadening the molecular weight distribution, improving the sensitivity of hydrogen adjustment, and widening the molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

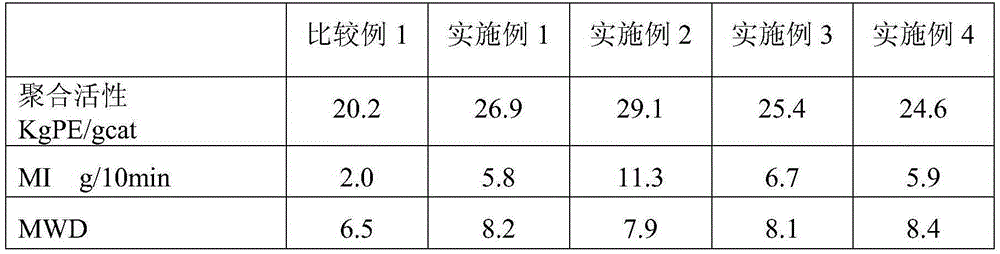

Examples

Embodiment 1

[0029] The preparation of catalyst (A) component:

[0030] In the high-purity N 2 In the fully replaced reactor, add 4.0g of anhydrous MgCl successively 2 , 28mL decane, 24mL 2-ethylhexanol, raise the temperature to 130°C with stirring, and maintain it for 3 hours, cool down to 50°C, add 3ml tetraethoxysilane, continue stirring for 2 hours, and then cool the solution to room temperature. In another high-purity N 2 Add 100ml of titanium tetrachloride to the fully replaced reactor, cool it to -5°C under stirring, slowly add the above-prepared solution into the titanium tetrachloride liquid, and slowly raise the temperature to 110°C in 3 hours after the drop is completed , and react at this temperature for 2 hours. The mother liquor was removed, and the solid was washed several times with hexane to obtain a solid catalyst component A.

[0031] Ethylene polymerization:

[0032] A stainless steel kettle with a volume of 2 liters was subjected to H 2 After full replacement, ad...

Embodiment 2

[0034] Others are the same as in Example 1, except that the Ti molar ratio between germanium tetrachloride and solid catalyst component A is changed to 90 during the polymerization, and the Ti molar ratio between monobromocyclopentane and solid catalyst component A is 5. See Table 1 for the data.

Embodiment 3

[0036] In the high-purity N 2 In the fully replaced reactor, add 4.0g of anhydrous MgCl successively 2 , 28mL decane, 24mL 2-ethylhexanol, raise the temperature to 130°C with stirring, and maintain it for 3 hours, cool down to 50°C, add 3ml tetraethoxysilane, continue stirring for 2 hours, and then cool the solution to room temperature. In another high-purity N 2 Add 100ml of titanium tetrachloride to the fully replaced reactor, cool it to -5°C under stirring, slowly add the above-mentioned prepared solution into the titanium tetrachloride liquid, and then add 3ml of germanium tetrachloride after dripping, The temperature was gradually raised to 110° C. over 3 hours, and the reaction was carried out at this temperature for 2 hours. The mother liquor was removed and the solid was washed several times with hexanes to give the product as a solid.

[0037] Ethylene polymerization: a stainless steel kettle with a volume of 2 liters is passed through H 2 After sufficient replace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com