Method for extracting nobiletin and tangeretin from citrus

A technology of tangerine peel and orange peel, which is applied in the field of plant extraction, can solve the problems of low extraction efficiency, single extraction components, and many elution times, and achieves the effects of improving extraction rate, simplifying technological process and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

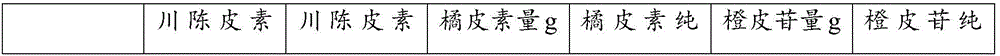

Image

Examples

Embodiment 1

[0050] The raw orange peel is produced in Jintang County, Sichuan. The orange peel is dried until the water content is lower than 10%, and then crushed and passed through a 30-mesh sieve.

[0051] Take 200g orange peel powder, add 1200mL 70% ethanol aqueous solution, then adjust pH=8 with 5% NaoH solution; reflux extraction at 80°C for 2 hours, filter and collect the filtrate; Reflux extraction at 80°C for 2 times, 1 hour each time. The three filtrates were combined to a total of 3000 mL. Recover ethanol with a rotary evaporator to obtain 450 mL of citrus flavonoid concentrate.

[0052] The concentrated solution of citrus flavonoids was extracted by adding ethyl acetate at a ratio of 1:3 for 3 times, each time for one hour, and the aqueous phase and the organic phase were separated; after the ethyl acetate was recovered from the organic phase, there was about 30 mL of concentrated solution of methoxylated flavones. Use a constant flow pump to pump ethyl acetate into the medi...

Embodiment 2

[0055] The raw orange peel is produced in Jintang County, Sichuan. The orange peel is dried until the water content is lower than 10%, and then crushed and passed through a 30-mesh sieve.

[0056] Take 200g of orange peel powder and add 5g of quicklime and mix evenly, then add 1200mL of 50% ethanol aqueous solution, reflux extraction at 80°C for 2 hours, filter and collect the filtrate; 1 hour each time. The three filtrates were combined to a total of 2900 mL. Recover ethanol with a rotary evaporator to obtain 400 mL of citrus flavonoid concentrate.

[0057] The concentrated solution of citrus flavonoids was extracted by adding ethyl acetate at a ratio of 1:3 for 3 times, each time for one hour, and the aqueous phase and the organic phase were separated; after the ethyl acetate was recovered from the organic phase, there was about 30 mL of concentrated solution of methoxylated flavones. Use a constant flow pump to pump ethyl acetate into the medium-pressure chromatography co...

Embodiment 3

[0060] The raw orange peel is produced in Jintang County, Sichuan. The orange peel is dried until the water content is lower than 10%, and then crushed and passed through a 30-mesh sieve.

[0061] Take 200g orange peel powder, add 1g potassium hydroxide, then add 1200mL 80% methanol aqueous solution, reflux extraction at 75°C for 2 hours, filter and collect the filtrate; Reflux extraction 2 times, 1 hour each time. The combined filtrates totaled 2900 mL. Recover ethanol with a rotary evaporator to obtain 400 mL of citrus flavonoid concentrate.

[0062] The citrus flavonoids concentrate was extracted by adding n-hexane at a ratio of 1:3 for 3 times, each time for one hour, and the aqueous phase and the organic phase were separated; after recovering the n-hexane from the organic phase, there was about 30 mL of the concentrated methoxylated flavones. Use a constant flow pump to pump n-hexane into the medium-pressure chromatographic column until the solvent flows out, pump the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com