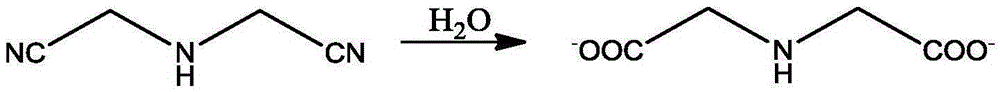

Method for preparing N1-(2-aminoethyl)-1,2-ethidene diamine

A technology of ethylenediamine and aminoethyl, applied in the field of organic amine synthesis, can solve the problems of incomplete elimination, process corrosion, complicated molecular sieve regeneration process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The treated 5g of Raney cobalt and 0.075g of 5% Ru / C were pre-added into a 1L high-pressure stainless steel hydrogenation reactor, and then 500g of iminodiacetonitrile with a mass fraction of 5% iminodiacetonitrile was added. Hexacyclic solution, and then add 17mg of NaOH to the reaction kettle. Replace with 0.3Mpa nitrogen for 3 times, then replace with 0.3MPa hydrogen for 3 times, then raise the temperature to 85°C, add hydrogen and carbon monoxide mixed gas (H 2 : CO=500:1, volume ratio) to a pressure of 5MPa, and stir to 1000 rpm. During the reaction process, the pressure of the mixer was maintained at 5MPa. At the same time, 20wt% formic acid was added dropwise when the amount of hydrogen absorbed by the reaction reached 10% of the theoretical value of hydrogen absorbed by the reaction, and 10% by weight of formic acid was added dropwise for every 10% increase in the amount of hydrogen absorbed later. The method for formic acid is that 25.5mg formic acid is added ...

Embodiment 2

[0069] Other conditions are the same as in Example 1, only the reaction temperature is changed to: 70°C, the reaction pressure is changed to 7.5MPa, the IDAN concentration is changed to 15%, the catalyst 1 quality is 5g, the catalyst 2 quality is 0.05g, and the auxiliary agent base is KOH , the quality is 37.5 mg, the acid added dropwise is glacial acetic acid, and the total mass is 61 mg; when the reaction starts, the volume ratio of feeding hydrogen and carbon monoxide gas mixture is H 2 : CO=1000:1, when the reaction reaches 25%, the system pressure is released to normal pressure, and the hydrogen is switched to high-purity hydrogen with a purity of 99.999%.

[0070] Catalyst application test results are as follows:

[0071] Apply times DETA selectivity % Piperazine selectivity % IDAN Conversion % Response time min 1 95.1 3.3 99.9 55 2 95.2 3.4 99.9 56 3 95.1 3.5 99.9 55 4 95.3 3.4 99.9 55 5 95.2 3.7 99.9 56 6 9...

Embodiment 3

[0073]Other conditions are the same as in Example 1, except that the reaction temperature is changed to 100° C., the reaction pressure is changed to 10 MPa, the IDAN concentration is changed to 25%, the mass of catalyst 1 is 5 g, and the mass of catalyst 2 is 0.025 g. The basic compound is KOH and the acidic compound is acetic acid. The quality of KOH is 66.5mg, and the quality of acetic acid is 133mg; When the reaction starts, the volume ratio of feeding hydrogen and carbon monoxide gas mixture is H 2 : CO=100:1, when the reaction reaches 30%, the system pressure is released to normal pressure, and the hydrogen is switched to high-purity hydrogen with a purity of 99.999%.

[0074] Catalyst application test results are as follows:

[0075] Apply times DETA selectivity % Piperazine selectivity % IDAN Conversion % Response time min 1 95.2 3.5 99.9 47 2 95.3 3.3 99.9 45 3 95.2 3.4 99.9 44 4 95.1 3.6 99.9 44 5 95.2 3.5 99.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com