Method of using black liquid extracted during pulping of corn straw through bioenzyme pretreatment and potassium hydroxide alkaline process to produce potassium fulvate organic fertilizer

A potassium hydroxide alkali method and a technology of corn stalks, applied in the field of papermaking, can solve problems such as unclear, unspecific, and difficult to implement, and achieve the effects of reducing waste liquid discharge, less water, and reducing sewage treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiment of the technical solution of the present invention is the three parts of the production of the pretreated black liquor and the finished product of potassium fulvic acid organic fertilizer:

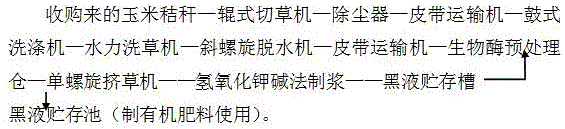

[0040] 1. Extraction of black liquor after bioenzyme pretreatment of corn stalks

[0041] 1.1 Wet preparation:

[0042] The corn stalks purchased from the farmers are transported to the mower and cut into 15-30mm long pieces. After being dedusted by the claw dust collector, they are conveyed by the belt conveyor, washed by drum washing machine and hydraulic grass washing machine, and then dehydrated. , to the next process.

[0043] 1.2 Black liquor extracted from corn stalks after biological enzyme pretreatment:

[0044] The washed and dehydrated corn stalks prepared by the wet method are transported to the biological enzyme pretreatment bin by the belt conveyor, and the washed corn stalks are subjected to biological enzyme pretreatment with the biological ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com