Manufacturing method of Si-O-C ceramic flexible substrate

A flexible substrate and ceramic technology, which is applied in the field of preparation of Si-O-C ceramic flexible substrates, can solve the problems that ceramic substrates cannot be used as flexible substrates, affect the performance stability of circuit substrates, and increase the process cost of coatings, etc., to achieve excellent chemical corrosion resistance High performance, good thermal conductivity, great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following embodiments will further describe the present invention in detail in conjunction with the accompanying drawings.

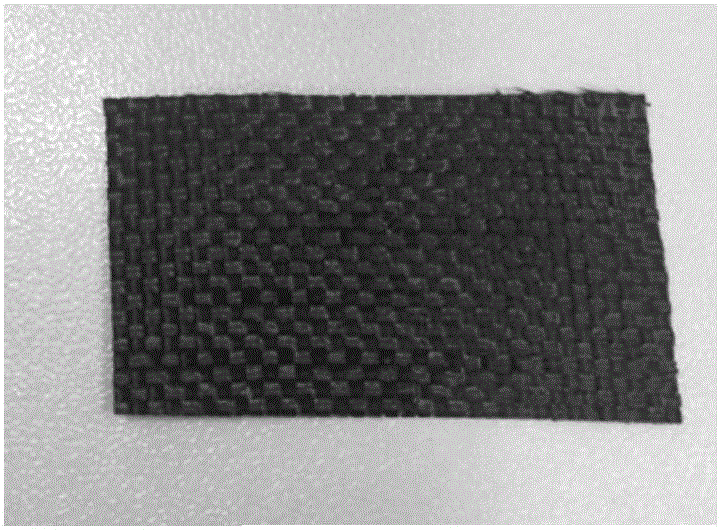

[0029] (1) Cut the single-layer carbon fiber plain cloth into a single-layer sheet of 30mm×50mm, with a thickness of 0.15mm, to form sample A;

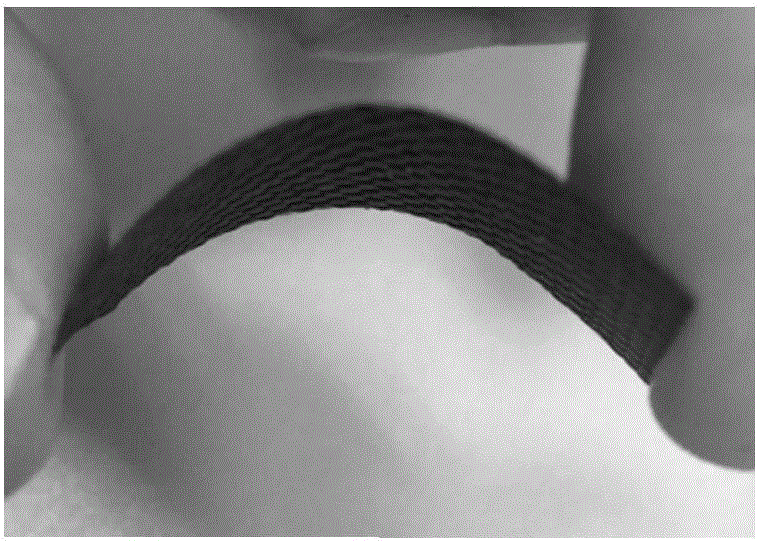

[0030] (2) Spread the sample A on a glass plate coated with a release agent, seal it with a vacuum bag and a vacuum tape, and draw a vacuum at any end of it. At this time, sample A is flattened under vacuum pressure to form sample B;

[0031] (3) Dissolving solid methyl silicone resin (softening point 70° C.) in ethanol solvent according to the mass ratio of 1:1 to obtain ethanol solution C of methyl silicone resin with a viscosity of 3 Pa·s;

[0032] (4) While keeping the vacuum at one end of sample B, use a catheter to introduce the ethanol solution C of methyl silicone resin from the opposite end. The resin soaks the fiber cloth under the action of vacuum. Blocked to form sample D.

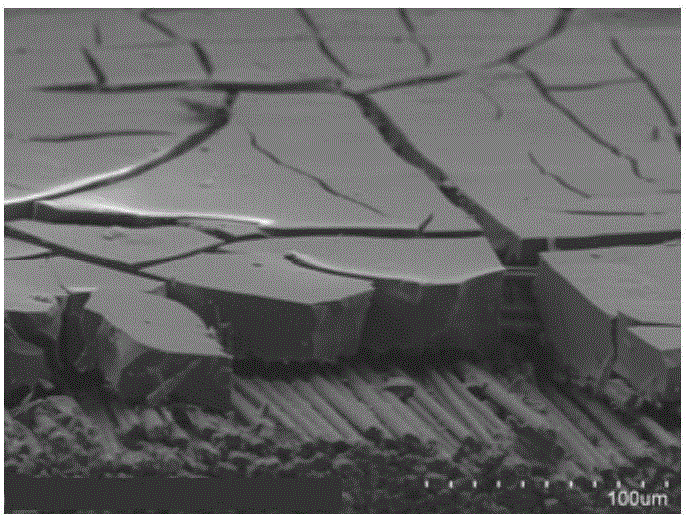

[0033] (5) Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com