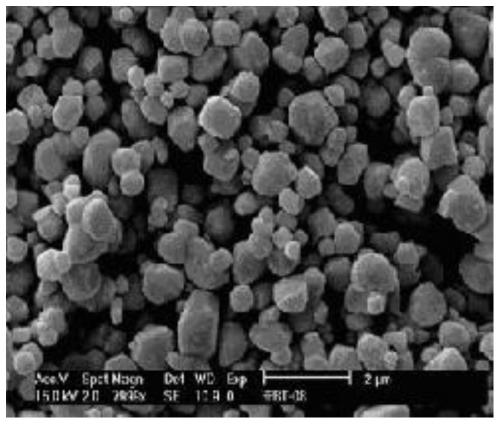

A process for preparing high-purity ultra-fine barium titanate by an improved liquid-phase precipitation method

A fine barium titanate, liquid phase precipitation technology, applied in the field of inorganic powder synthesis, can solve the problems of complex process route, easy powder agglomeration, high energy consumption of calcination, etc., to reduce the impurity content of the product, reduce the impurity content and agglomeration of the product , the effect of increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

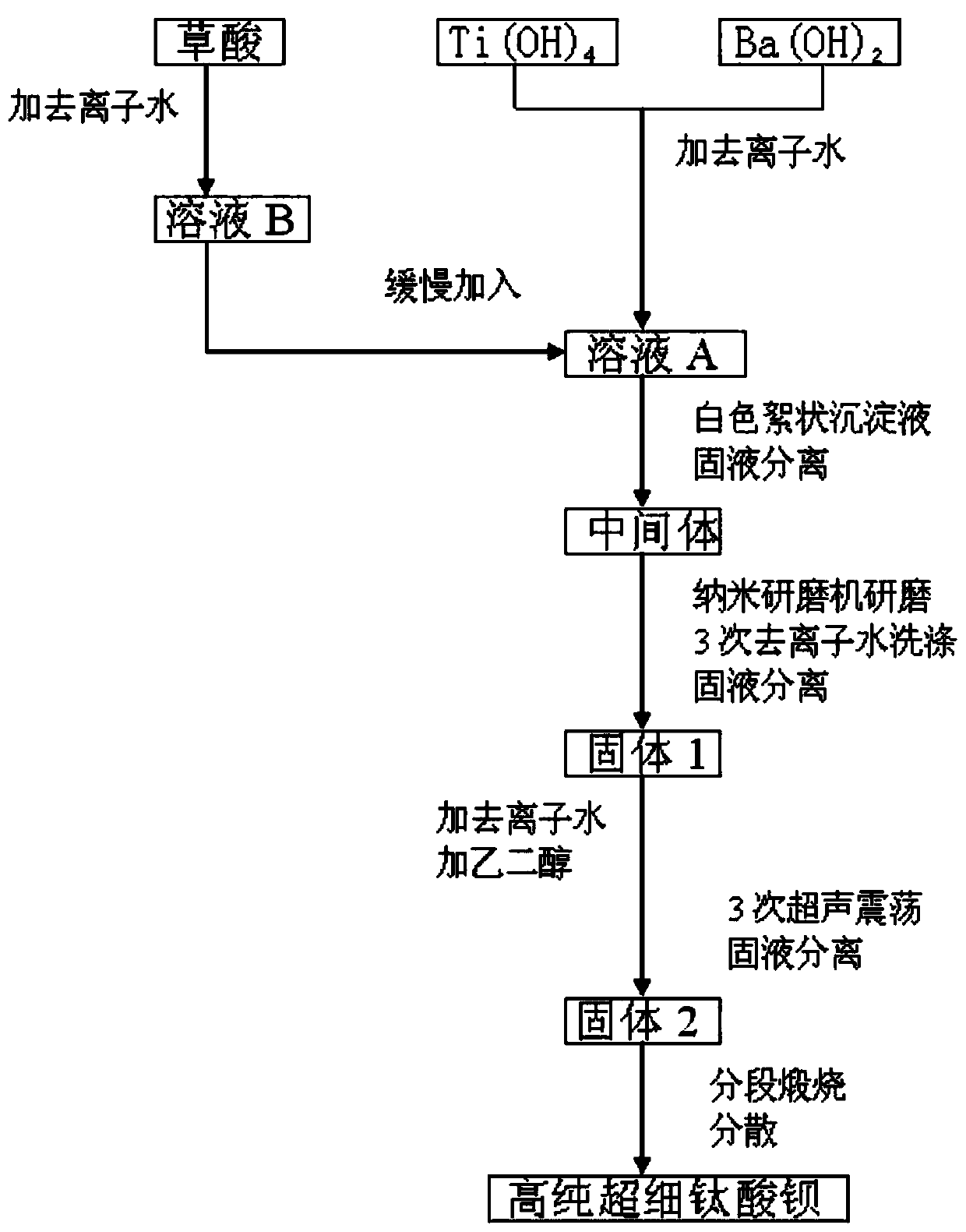

Method used

Image

Examples

Embodiment 1

[0029] Take 500ml of solution A and put it in a beaker, take 200ml of solution B and put it in a conical flask, put the beaker in a magnetic stirrer, add a polytetrafluoroethylene stirrer, turn on the strong magnetic stirrer, plug the conical flask with a rubber stopper and insert it into a tape Hang the glass tube with a flow regulating device upside down above the beaker, add solution B into the beaker at a rate of 1 drop / s, form a white precipitate and stabilize it for 30 minutes as the reaction end point, and centrifuge to obtain a white wet residue 1, which is the intermediate.

[0030] The intermediate was washed with 350 ml of deionized water, followed by solid-liquid separation, which was repeated three times to obtain solid 1.

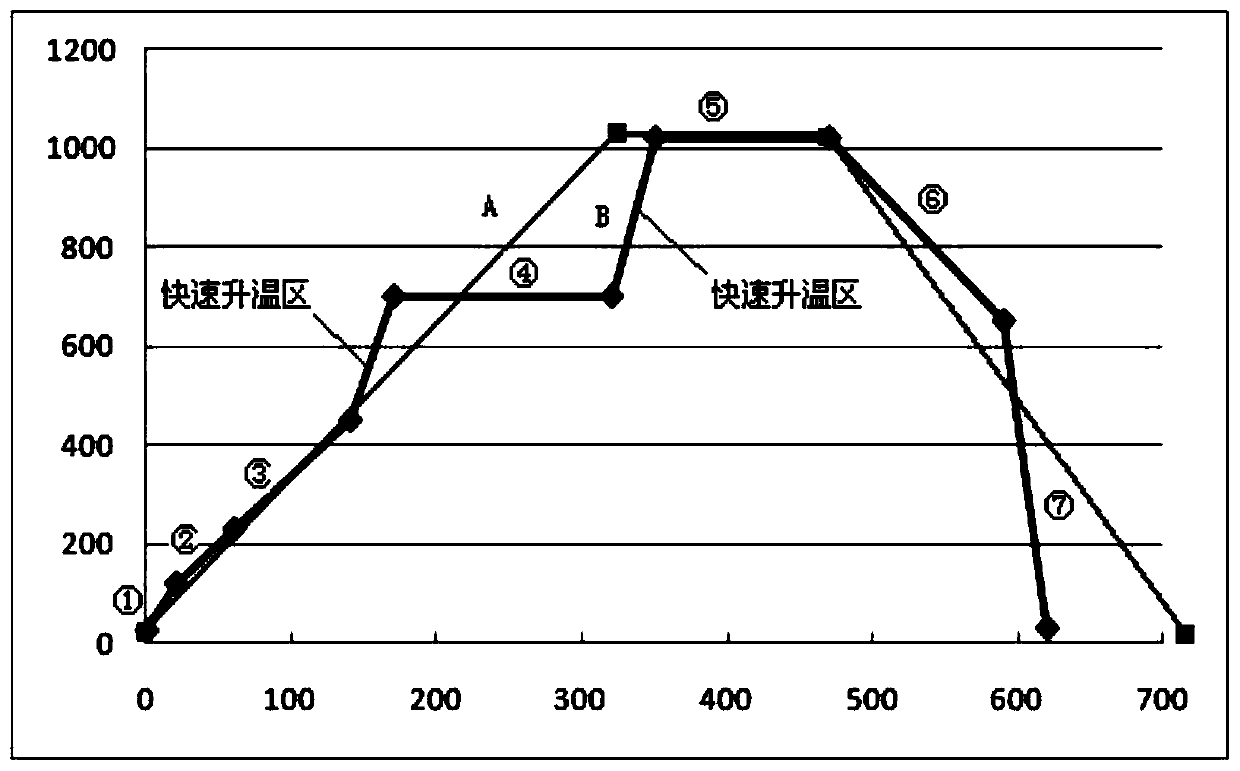

[0031] Transfer solid 1 into a reaction kettle with a high-frequency ultrasonic device, add 560ml of deionized water to the reaction kettle, add 28g of ethylene glycol, turn on the ultrasonic oscillator, set the frequency to 25000HZ, control th...

Embodiment 2

[0035] Take 2000ml of solution A in a beaker, take 1000ml of solution B in a conical flask, place the beaker in a magnetic stirrer, add a polytetrafluoroethylene stirrer, turn on the strong magnetic stirring, plug the conical flask with a rubber stopper and insert it into a tape Hang the glass tube with a flow regulating device upside down above the beaker, add solution B into the beaker at a rate of 0.5 drops / s, form a white precipitate and stabilize it for 50 minutes as the reaction end point, and centrifuge to obtain a white wet residue 1, which is the intermediate.

[0036] After the intermediate was washed with 1500ml deionized water, the solid-liquid separation was repeated for 3 times to obtain the solid 1.

[0037] Transfer the solid 1 into a reaction kettle with a high-frequency ultrasonic device, add 2500ml of deionized water to the reaction kettle, add 125g of ethylene glycol, turn on the ultrasonic oscillator, set the frequency to 30000HZ, and the temperature to 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com