Electrically heated head-up display laminated glass

A head-up display and laminated glass technology, applied in the field of head-up display, can solve problems such as cost increase, difficulty in optimizing composite functions, complex process and other problems, and achieve good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

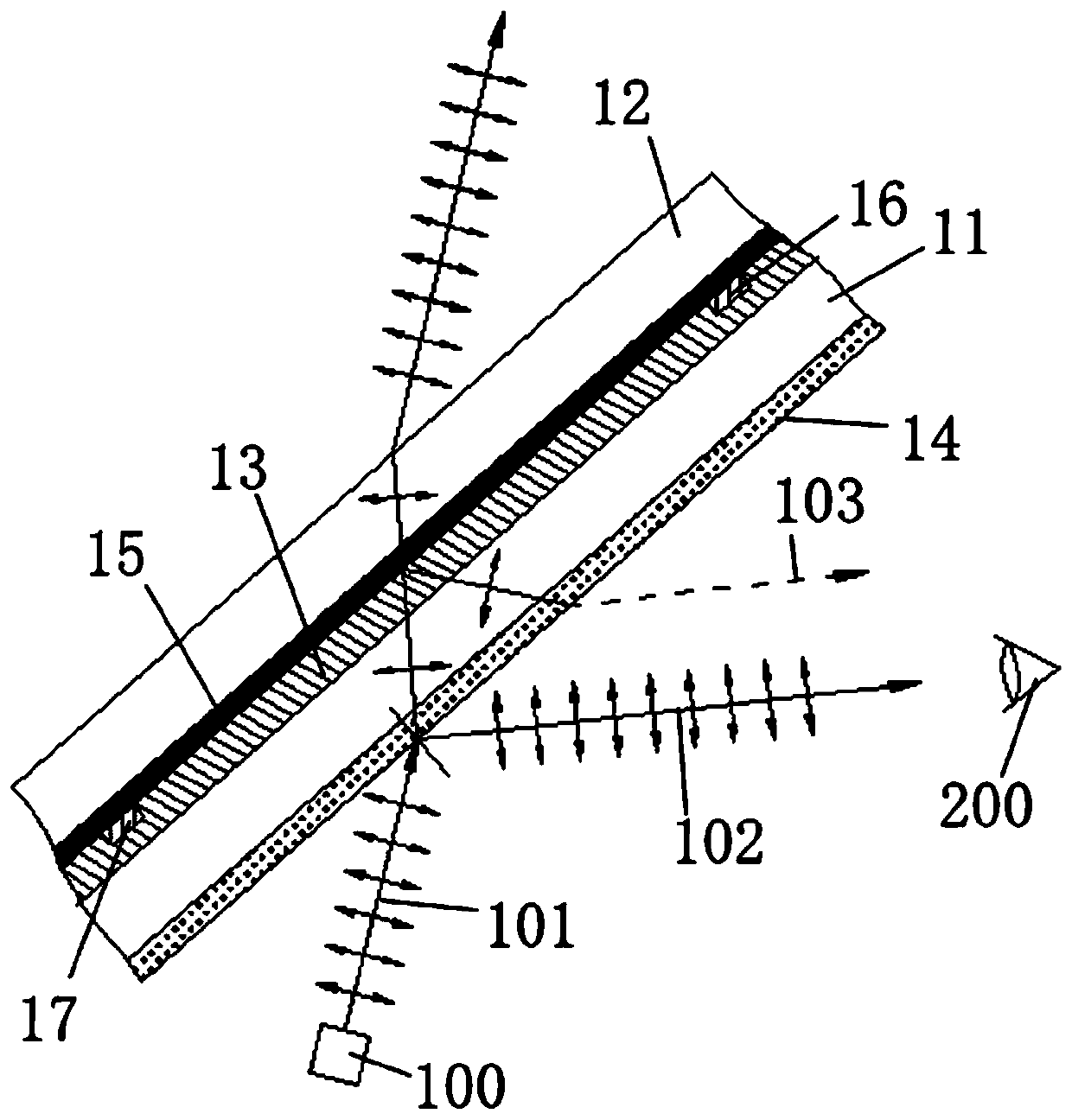

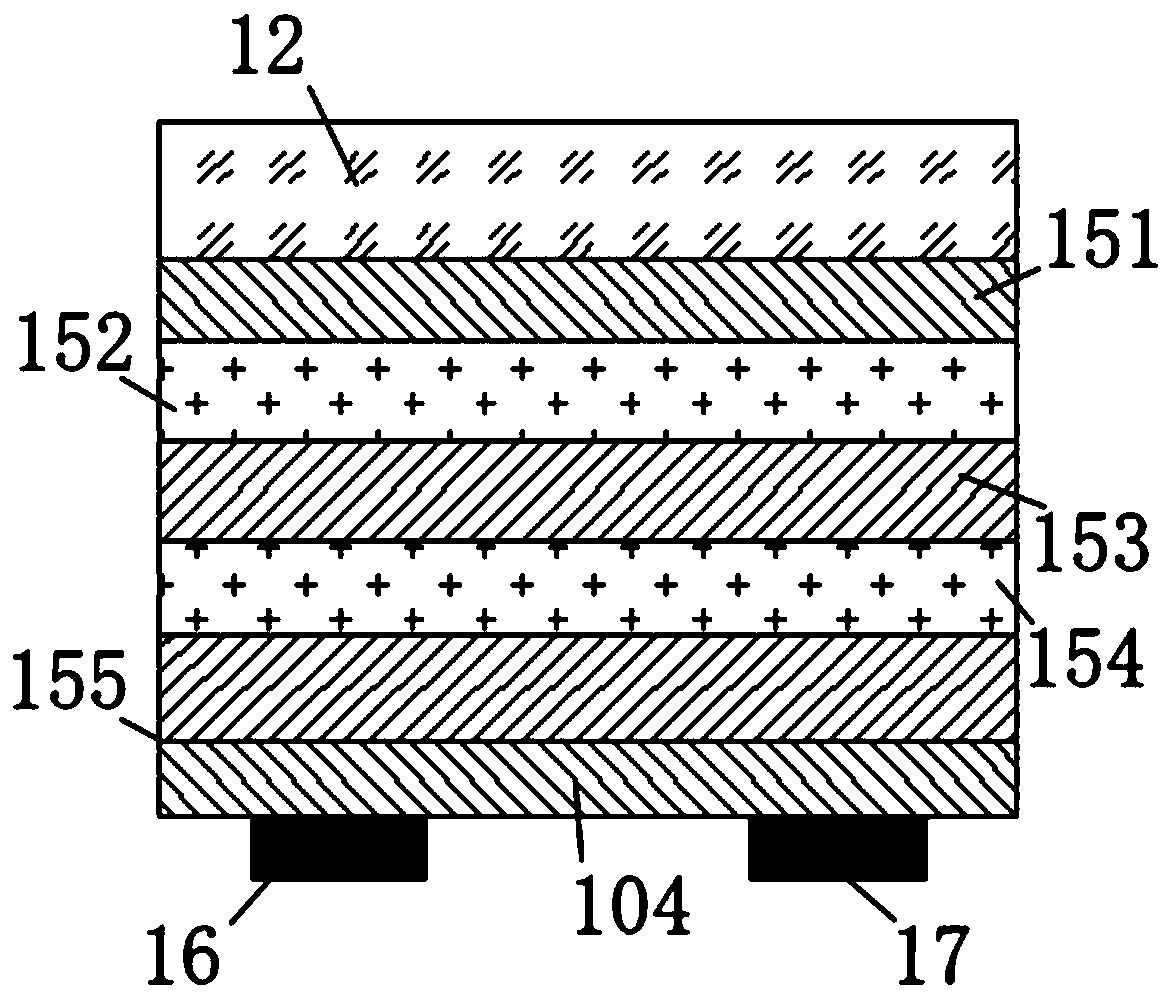

Embodiment 1

[0062] Soda lime silicate float glass with a thickness of 2.1mm produced by Fuyao Group is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for coating deposition. Two pieces The transparent nano-film and the conductive low-emissivity (Low-E) coating including two silver layers were deposited on the glass substrate respectively, and the conductive low-emissivity (Low-E) coating was completed and then printed on the glass substrate by screen printing. Two layers of ink containing silver nanoparticles are arranged on the conductive low-emissivity coating, and after the ink is dried at 200-250°C, the two glass substrates are matched. It is pasted on two inks containing silver nanoparticles to form the first electrode and the second electrode, and then a piece of PVB film with a thickness of 0.76 mm is sandwiched in the middle. After the initial pressure and high pressure process of the film and the installation of ac...

Embodiment 2~4

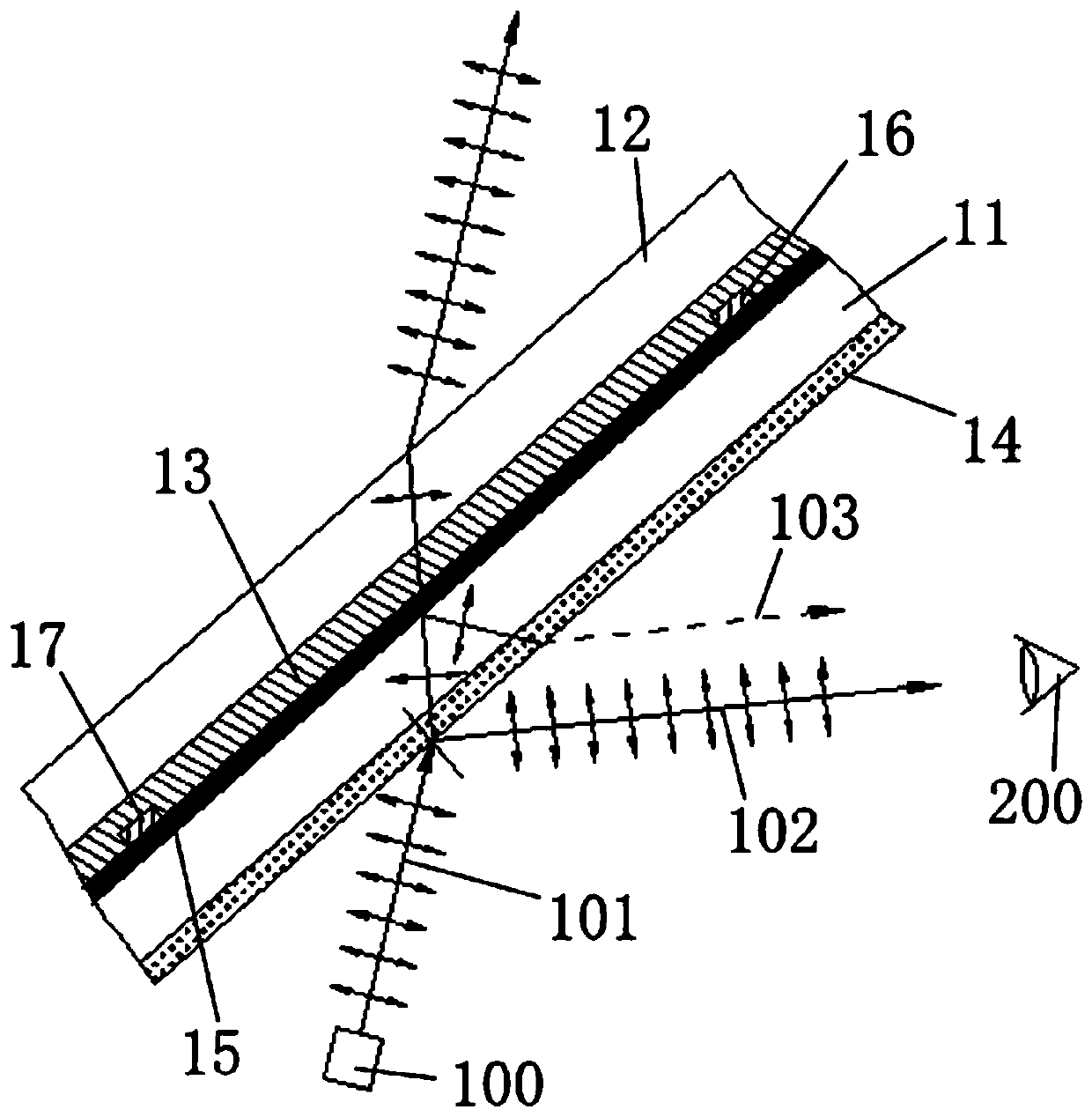

[0068] Soda lime silicate float glass with a thickness of 1.6mm produced by Fuyao Group is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for coating deposition. The transparent nano-film and the conductive low-emissivity coating in Table 2 are respectively deposited on the two surfaces of the glass substrate of mm, wherein the conductive low-emissivity (Low-E) coating is completed and then screen-printed on the conductive low-emissivity coating Arrange two inks containing silver nanoparticles, and after drying the inks at 200-250°C, match the two glass substrates. Form the first electrode and the second electrode on the printing ink of silver nanoparticle, then sandwich a piece of PVB film with a thickness of 0.76 millimeters in the middle, and make the interlayer of the present invention through the initial pressure and high pressure process of lamination and the annex installation of other processes glass pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com