Novel micro-bubble generator for air-flotation treatment of water extracted from oil field and analysis method thereof

A technology of micro-bubble generator and water gas, which is applied in mining wastewater treatment, separation method, flotation water/sewage treatment, etc. It can solve the problems of poor equipment adaptability, fixed, simple internal flow path, etc., and achieve operation and maintenance Convenient, simple structure, not easy to block effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] The novel micro-bubble generator for air flotation treatment of oilfield produced water of the present invention, its preferred embodiment is:

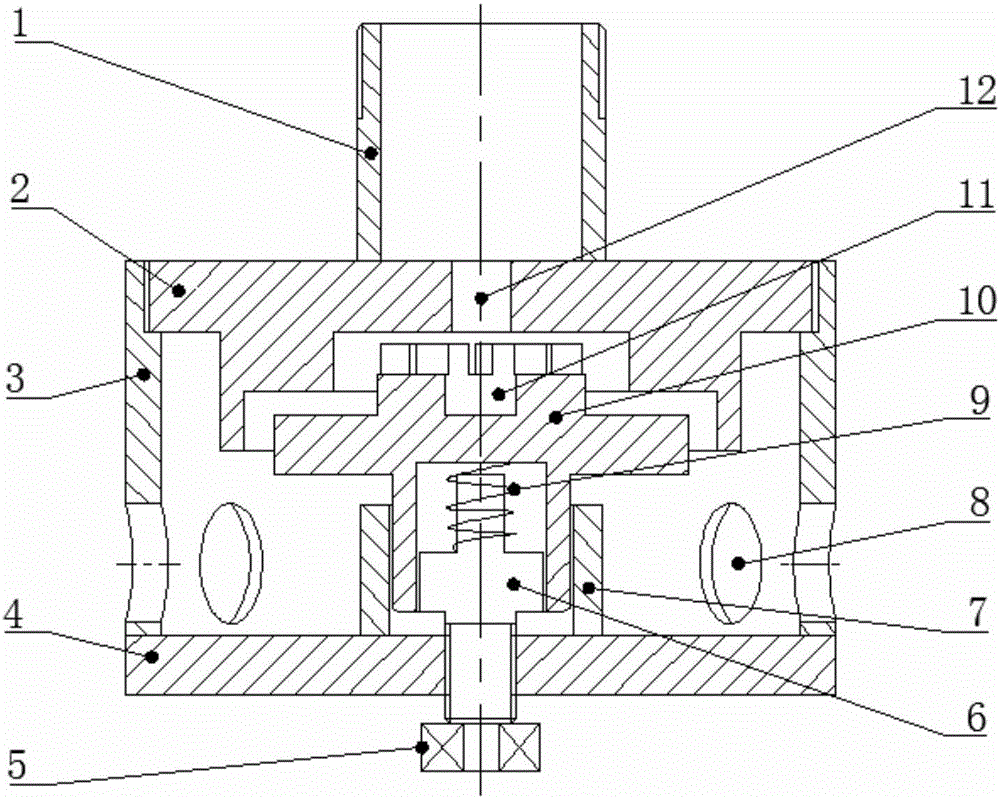

[0024] Including water inlet pipe, upper cover plate, outer wall tube, lower cover plate, core body, spring support seat, compression spring, lock nut;

[0025] The outer wall tube has a cylindrical structure, which is threadedly connected with the upper cover plate and welded with the lower cover plate. A plurality of outlet holes (recommended to be 12) are evenly arranged in the lower part of the outer wall tube along the radial direction. The core body is placed in the space surrounded by the outer wall tube, the upper cover plate and the lower cover plate;

[0026]The lower part of the upper cover plate is an inner ring stepped structure with an orifice in the center. The upper structure of the core body corresponds to the lower structure of the upper cover plate, forming a wide flow channel with multiple right-angle turns....

specific Embodiment

[0040] Such as figure 1 As shown, it includes a water inlet pipe 1 , an upper cover plate 2 , an outer wall tube 3 , a lower cover plate 4 , a core body 10 , a spring support seat 6 , a compression spring 9 and a locking nut 5 . Among them, the water inlet pipe 1, the upper cover plate 2 and the core body 10 form the energy-dissipating and pressure-reducing flow channel of the micro-bubble generator; Stable flow space; spring support seat 6, compression spring 9, lock nut 5 and core body 10 constitute the adjustment mechanism of the microbubble generator; The upper cover plate 2 and the core body 10 are composed. The upper cover plate 2 has a stepped inner ring structure, and the boss position is composed of two inner rings with different diameters, and a throttling hole 12 (through hole) is opened at the center of the circle. The structure of the core body 10 is divided into upper and lower parts. The upper part is a boss structure, which corresponds to the inner ring of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com