Subsea pipeline in-situ overhaul bin

A subsea pipeline and in-situ technology, applied in the direction of pipes, pipes/pipe joints/fittings, underwater operation equipment, etc., can solve the problems of secondary damage to the network, large economic losses, low operating efficiency, etc., and achieve strong carrying capacity, The effect of a high degree of automation and a large depth of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described below.

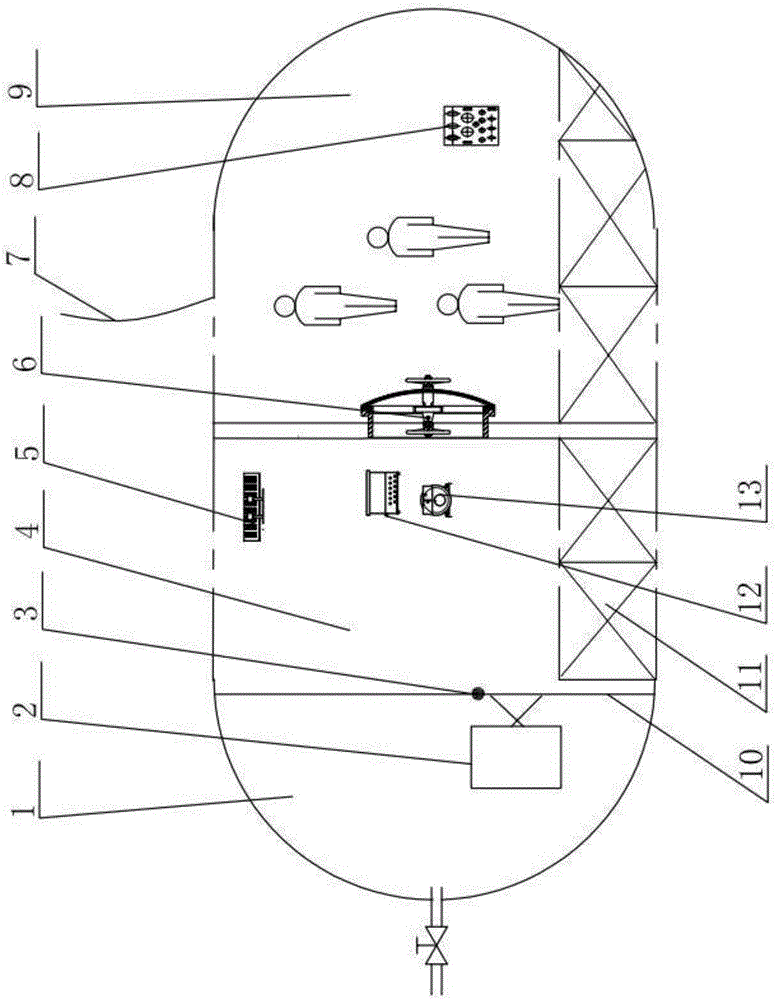

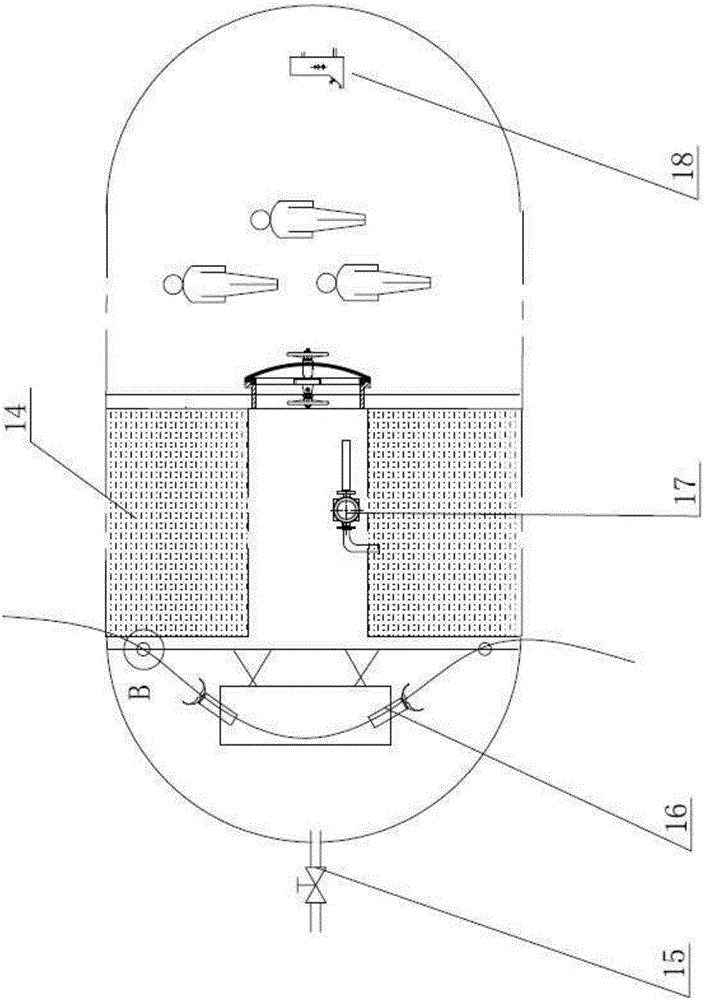

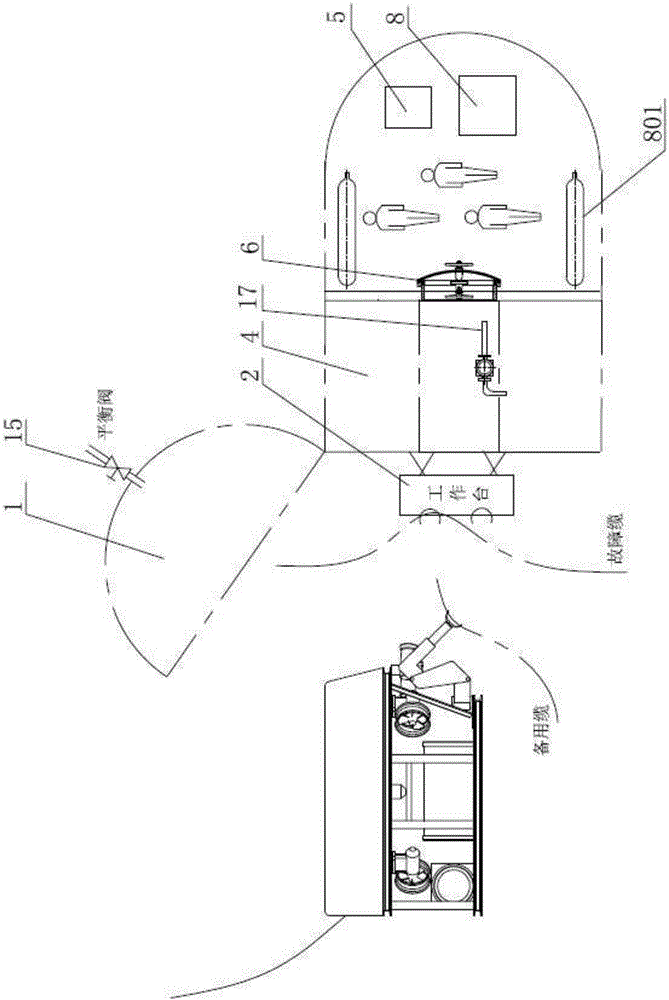

[0036] Such as figure 1 , figure 2 and image 3 As shown, a submarine pipeline in-situ maintenance cabin is composed of a dry and wet cabin 4 and a manned cabin 9 to form a pressure-resistant shell. One side of the dry and wet cabin 4 and the manned cabin 9 are provided for communicating with the dry and wet cabin. 4 and the opening and closing door 6 of the manned cabin 9, an automatic opening and closing hatch cover 1 is also arranged on the other side of the dry and wet cabin 4, which is located inside the automatic opening and closing hatch cover 1, and the above-mentioned automatic opening and closing hatch cover 1 is The channel of communication between the dry and wet cabin 4 and the seawater outside the cabin can provide the working space for the underwater robot that can assist the operation, and provide the feasibility for the pipeline to enter the cabin. An electric control system 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com