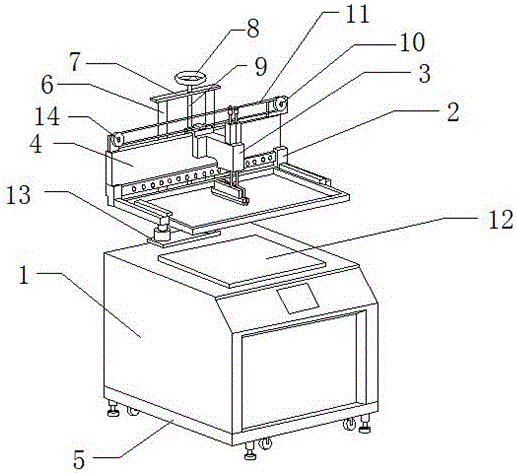

Automatic silk-screen printing device

A screen printing device and screw rod technology, which is applied to screen printing machines, printing machines, printing machines, etc., can solve the problems of affecting the cleanliness of the working environment, difficult manual handling, and reduced application range, and achieves simple plate making, accurate and firm positioning, and reduced The effect of small purchases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

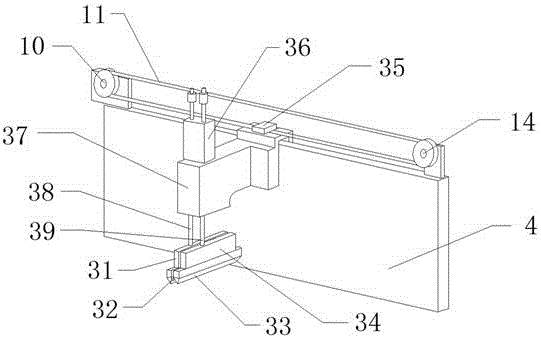

[0029]Specific embodiments: first, after the present invention is moved to a suitable position required for production, the operator applies a counterclockwise force to the support piece 53, and the support piece 53 is subjected to the force to rotate counterclockwise, driving the screw 55 to rotate counterclockwise, so that The screw 55 is extracted from the nut 54. As the operator continues to apply force to the support plate 53, the exposed part of the screw 55 becomes larger and larger. When the universal wheel 52 is in the suspended state, stop applying force to the support plate 53. Personnel apply a clockwise force to the support piece 53, and the universal wheel 52 slowly fits the ground to achieve fast switching between fixed and mobile. This design solves the problem of difficult handling of screen printing equipment and reduces the labor intensity of workers. It is convenient for workers to quickly carry the screen printing equipment, saves time and improves work eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com