Efficient shoe sole mold integrating heating and cooling

A shoe sole mould, a high-efficiency technology, applied in the field of moulds, can solve problems such as unstable product shaping, shortening the service life of molds, and affecting the appearance of finished products, achieving the effects of improving appearance quality, shortening manufacturing cycle, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

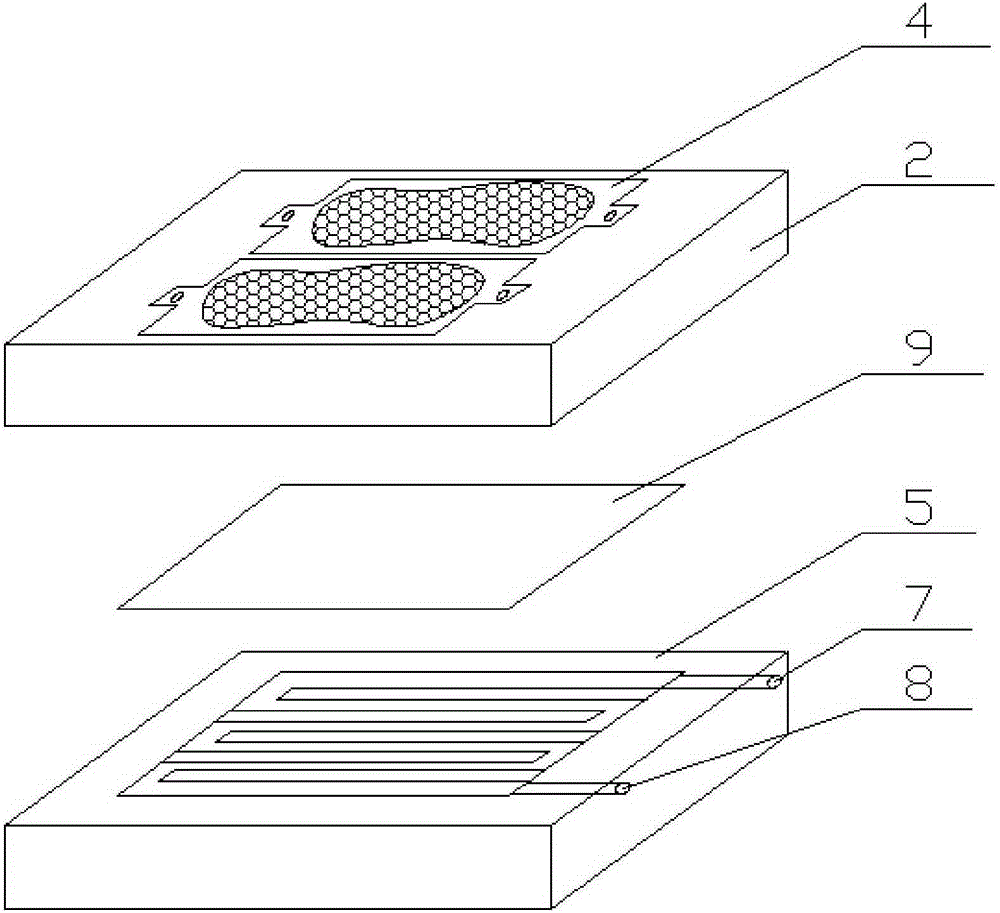

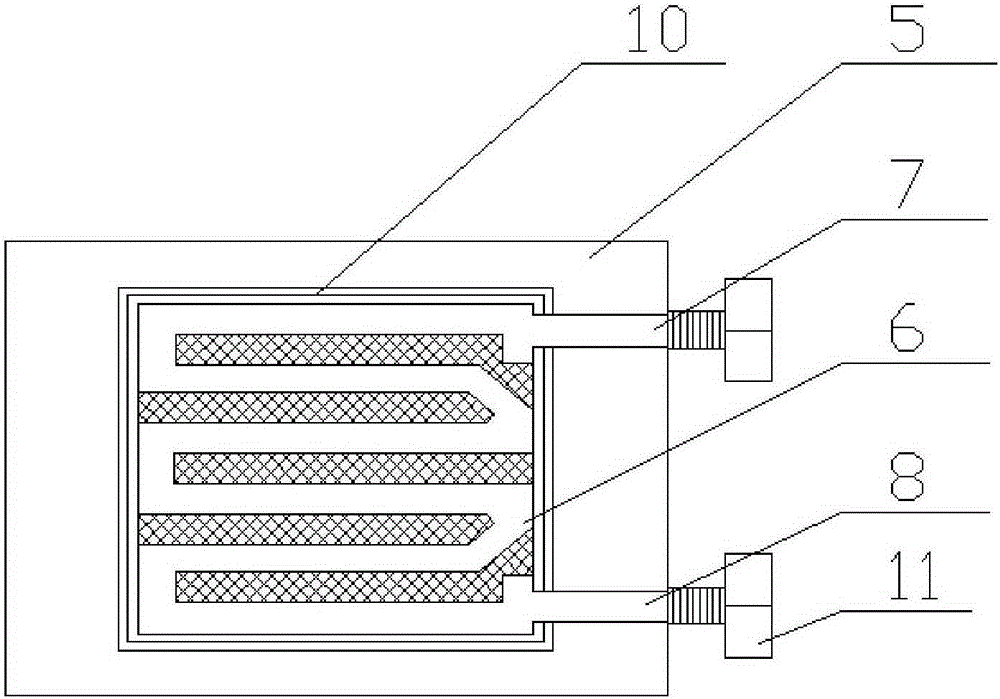

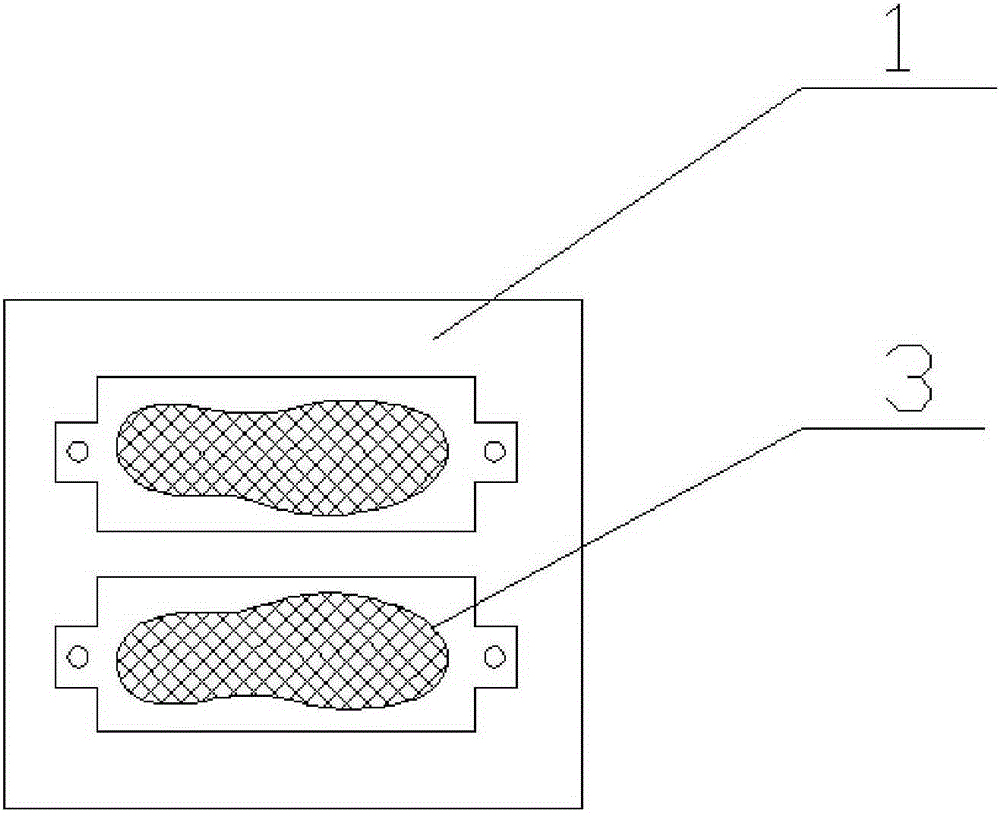

[0019] refer to Figure 1-Figure 4 , a high-efficiency shoe sole mold integrated with heating and cooling, comprising an upper template 1 and a lower template 2, the inner surface of the upper template 1 is provided with a core 3, and the inner surface of the lower template 2 is provided with a cavity 4, the core 3 and the inner surface of the lower template 2 are provided with a cavity 4. The cavity 4 is detachably installed on the upper template 1 and the lower template 2 respectively, and the outer surfaces of the upper template 1 and the lower template 2 are respectively detachably connected with a heating and cooling plate 5, and the inner surface of the heating and cooling plate 5 is provided with The heating and cooling channel 6 that circulates back and forth in parallel, one end of the heating and cooling channel 6 is connected to the inlet 7, and the other end of the heating and cooling channel 6 is connected to the outlet 8, and the heating and cooling channel 6 is c...

Embodiment 2

[0021] refer to Figure 1-Figure 4 , a high-efficiency shoe sole mold integrated with heating and cooling, comprising an upper template 1 and a lower template 2, the inner surface of the upper template 1 is provided with a core 3, and the inner surface of the lower template 2 is provided with a cavity 4, the core 3 and the inner surface of the lower template 2 are provided with a cavity 4. The cavity 4 is detachably installed on the upper template 1 and the lower template 2 respectively, and only the core and the cavity can be replaced to produce non-stop shoe soles, reducing production costs. The outer surfaces of the upper template 1 and the lower template 2 are respectively detachable is connected with a heating and cooling plate 5, the inner surface of the heating and cooling plate 5 is provided with a heating and cooling channel 6 that circulates back and forth in parallel, one end of the heating and cooling channel 6 is connected to the inlet 7, and the other end of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com