A foam roller blind production system

A production system and rolling shutter technology, which is applied in the direction of manufacturing tools, other household appliances, and other manufacturing equipment/tools, etc., can solve the problems of difficult processing of aluminum alloys, irregular ports, loud noises, etc., to ensure the quality of punching , the effect of convenient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

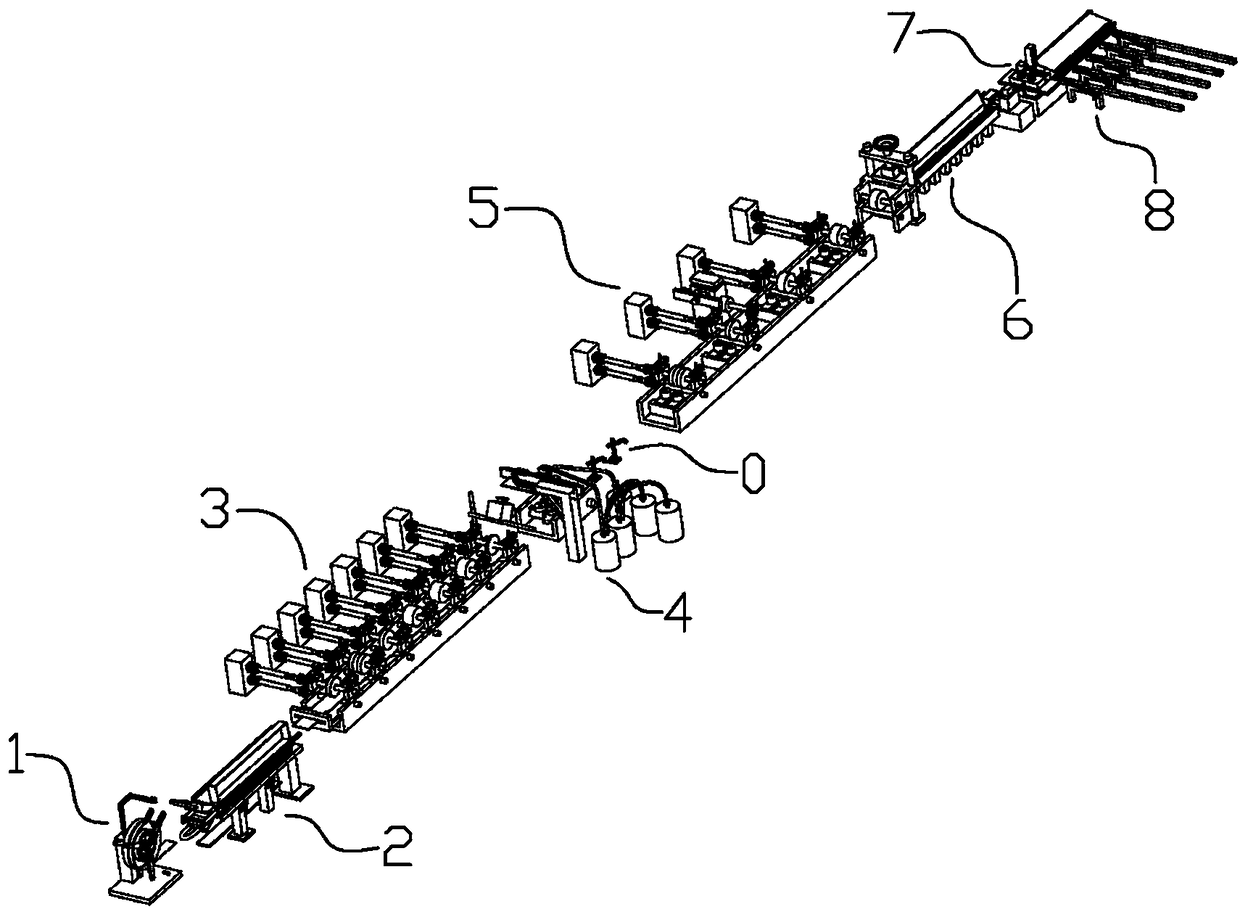

[0039] Example 1: Reference Figure 1~Figure 8 , a foaming roller shutter production system, used to produce roller shutter aluminum filled with foaming materials, according to the transmission direction of the aluminum material, an aluminum material winding device 1, an aluminum material surface pretreatment device 2, a filling form rolling Wheel set device 3, foam material filling device 4, roller shutter sheet form rolling wheel set device 5, foam material reaction device 6, cutting device 7 and roll shutter aluminum material unloading device 8; the aluminum material is wound from the aluminum material The output of the device 1 is sequentially passed through the above-mentioned devices to form a rolling aluminum material, and then cut by the cutting device 7 and then unloaded and collected by the rolling aluminum material unloading device 8;

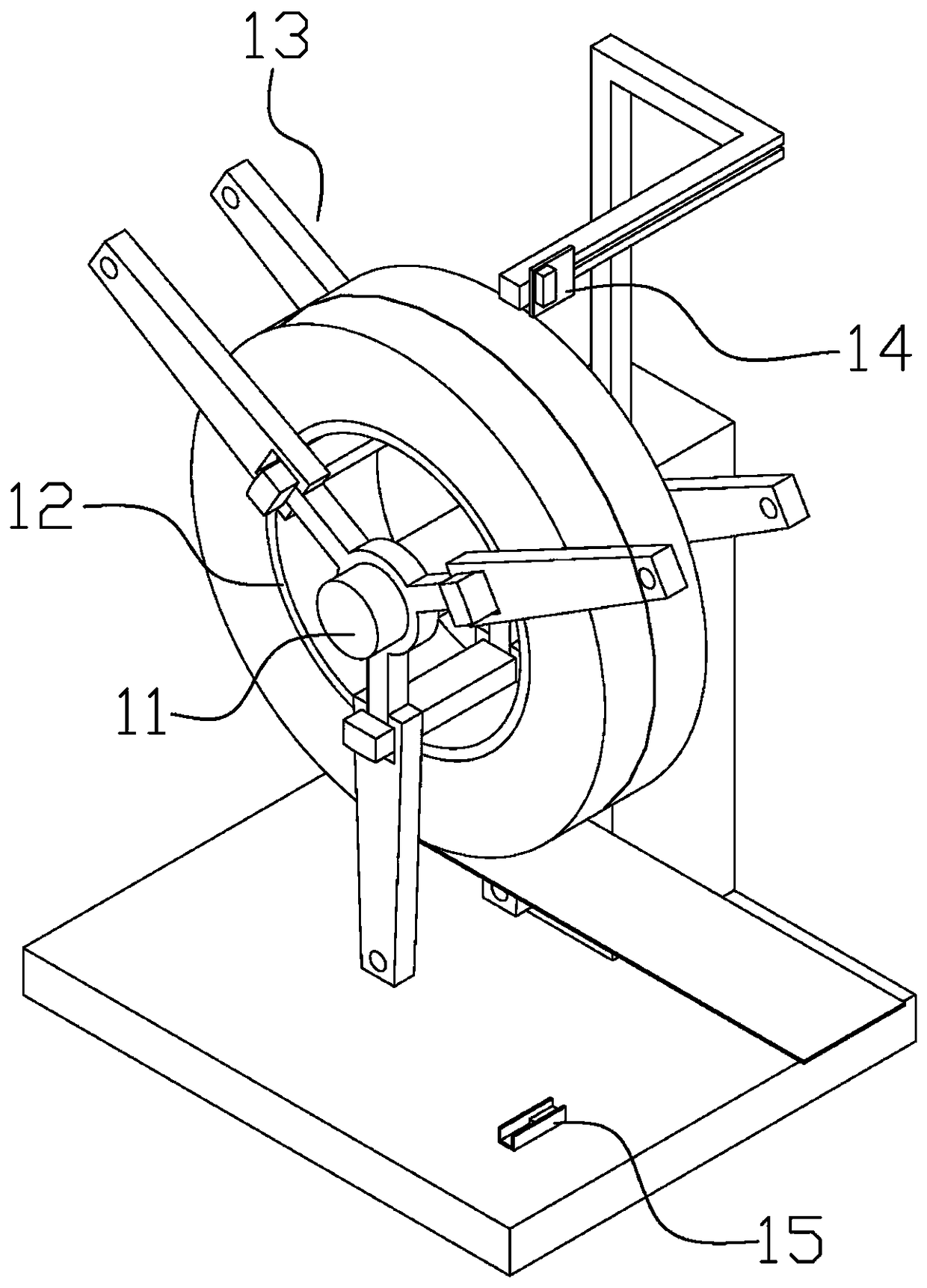

[0040] The aluminum material winding device 1 includes a rotating shaft 11 and an aluminum material winding drum 12 arranged outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com