Method for manufacturing aluminum alloy flux-cored wire by utilizing powder sheath extrusion blank-making method

A technology of flux-cored welding wire and aluminum alloy, which is applied in the field of material engineering, can solve problems such as unstable filling coefficient of active agent, influence on welding quality, and uneven distribution, and achieve the effects of reducing cost increase, improving quality, and improving metallurgical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

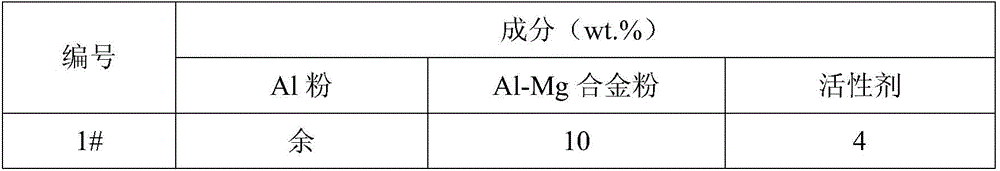

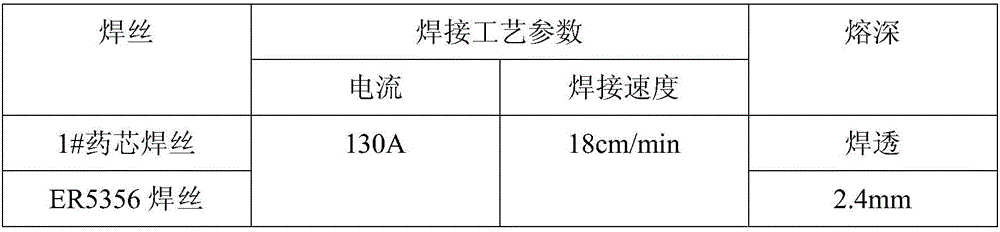

[0019] Prepare 1# aluminum alloy flux-cored welding wire, the composition and formulation are shown in Table 1. Among them: the mass fraction of Mg in the Al-Mg alloy powder is 50%, and the composition (wt.%) of the active agent is SiO 2 : 40%, MgF 2 :20%, CaCl 2 : 40%. The particle size of Al powder, Al-Mg alloy powder, and active agent are -100~+200 mesh.

[0020] Table 1 1# flux cored wire composition

[0021]

[0022] The steps of the manufacturing method of 1# aluminum alloy flux cored wire are:

[0023] 1. Mixed charging

[0024] The active agent, aluminum powder, and aluminum-magnesium alloy powder are ball-milled and mixed uniformly, and packed into an aluminum alloy sheath. The sheath is made of LF6 aluminum alloy with a diameter of φ120mm and a height of 140mm.

[0025] 2. Hot vacuum

[0026] Vacuum the powder jacket. When the vacuum degree reaches 10-1Pa level, start heating and keep warm. The heating temperature is 350℃, the holding time is 7h, and the vacuum degree in the ...

Embodiment 2

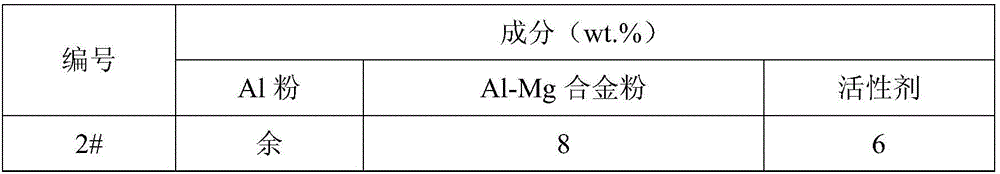

[0040] Prepare 2# flux-cored welding wire, as shown in Table 3. Wherein: the mass fraction of Mg in the Al-Mg alloy powder is 50%, and the composition (wt.%) of the active agent is SiO2: 30%, MgF2: 30%: CaCl2: 40%. The particle size of Al powder, Al-Mg alloy powder, and active agent are -100~+200 mesh.

[0041] Table 3 2# flux cored wire composition

[0042]

[0043] The steps of 2# aluminum alloy flux-cored welding wire manufacturing method are:

[0044] 1. Mixed charging

[0045] The active agent, aluminum powder, and aluminum-magnesium alloy powder are ball-milled and mixed uniformly, and packed into an aluminum sheath. The sheath is made of LF6 aluminum alloy with a diameter of φ120mm and a height of 140mm.

[0046] 2. Hot vacuum

[0047] Vacuum the powder jacket. When the vacuum degree reaches 10-1Pa level, start heating and keep warm. The heating temperature is 350℃, the holding time is 7h, and the vacuum degree in the jacket reaches 10-3Pa level, and then it is sealed.

[0048] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com