High-adsorbability activated semi-coke as well as preparation method and application thereof

An active semi-coke and high adsorption technology, which is applied in the field of coal chemical industry, can solve the problems of specific surface area difference and overall low level, and achieve the effect of low cost, good adsorption performance and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

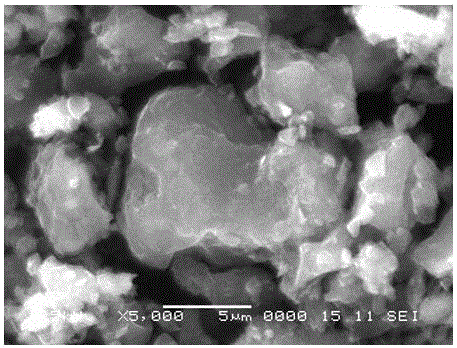

Image

Examples

Embodiment 1

[0034] A preparation method of high-adsorption active semi-coke includes the following steps:

[0035] Step 1: Crush the raw semi-coke: crush the raw semi-coke to semi-coke particles with a diameter of no more than 0.5mm; the specific process is: use the quarter method to reduce the sample, first use a jaw crusher to moderately crush, and then use a ball mill Crushing, and finally sieving the crushed semi-coke with 0.5mm, 0.25mm, 0.125mm, 0.074mm sieves in sequence, and further crushing the semi-coke that cannot pass through the 0.5mm sieve until all samples can pass the sieve;

[0036] Step two, deashing treatment: de-ashing the semi-coke particles obtained in step 1 by flotation to obtain ultra-pure semi-coke;

[0037] Step three, ZnCl 2 Activation: Combine the ultra-pure semi-coke obtained in step two with ZnCl 2 Mix evenly according to the mass ratio of 1:2.0 to obtain ultra-pure semi-coke and ZnCl 2 Mixture of ultra-pure semi coke and ZnCl 2 The mixture is placed in a heating fu...

Embodiment 2

[0046] A method for preparing high-adsorption active semi-coke includes the following steps:

[0047] Step 1: Crush the raw semi-coke: crush the raw semi-coke to semi-coke particles with a diameter of no more than 0.5mm; the specific process is: use the quarter method to reduce the sample, first use a jaw crusher to moderately crush, and then use a ball mill Crushing, and finally sieving the crushed semi-coke with 0.5mm, 0.25mm, 0.125mm, 0.074mm sieves in sequence, and further crushing the semi-coke that cannot pass through the 0.5mm sieve until all samples can pass the sieve;

[0048] Step two, deashing treatment: chemically deashing the semi-coke particles obtained in step 1 to obtain ultra-pure semi-coke;

[0049] Step three, ZnCl 2 Activation: Combine the ultra-pure semi-coke obtained in step two with ZnCl 2 Mix evenly according to the mass ratio of 1:3.5 to obtain ultra-pure semi-coke and ZnCl 2 Mixture of ultra-pure semi coke and ZnCl 2 The mixture was placed in a tube furnace,...

Embodiment 3

[0059] A method for preparing high-adsorption active semi-coke includes the following steps:

[0060] Step 1: Crush the raw semi-coke: crush the raw semi-coke to semi-coke particles with a diameter of no more than 0.5mm; the specific process is: use the quarter method to reduce the sample, first use a jaw crusher to moderately crush, and then use a ball mill Crushing, and finally sieving the crushed semi-coke with 0.5mm, 0.25mm, 0.125mm, 0.074mm sieves in sequence, and further crushing the semi-coke that cannot pass through the 0.5mm sieve until all samples can pass the sieve;

[0061] Step two, deashing treatment: the semi-coke particles obtained in step 1 are deashed first by flotation, and then deashed by chemical methods to obtain ultra-pure semi-coke;

[0062] Step three, ZnCl 2 Activation: Combine the ultra-pure semi-coke obtained in step two with ZnCl 2 Mix evenly according to the mass ratio of 1:2.5 to obtain ultra-pure semi-coke and ZnCl 2 Mixture of ultra-pure semi coke and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cod removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com