Fly ash modifying method based on passivation of heavy metals in stored sludge

A fly ash and heavy metal technology, applied in chemical instruments and methods, sludge treatment, sludge detoxification, etc., can solve soil and groundwater pollution hazards, threats to the health of surrounding residents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0011] Embodiment 1: In this embodiment, a method for modifying fly ash based on heavy metals in passivation storage sludge is carried out in the following steps:

[0012] 1. Soak the fly ash in the acidic solution for 4 hours, then place it in an air bath constant temperature oscillator and shake it for 90 minutes at a temperature of 20°C and 250r / min. The H in the acidic solution + The concentration is 4mol / L, and the acid-ash ratio is 3ml:1g;

[0013] 2. Centrifuge at 10,000r / min for 10min, remove the acid solution and wash the acid-modified fly ash repeatedly with ultrapure water until neutral;

[0014] 3. Dry at 105±2°C to constant weight, crush and pass through a 100-mesh sieve, and then heat at 105±2°C for 2 hours to complete the fly ash modification.

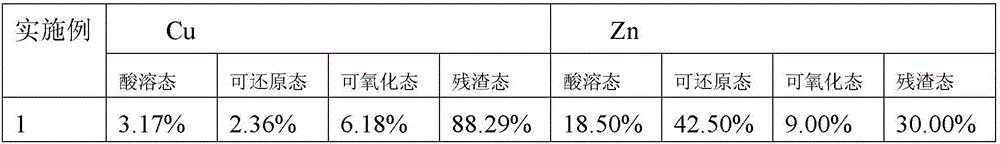

[0015] Sludge is different from wastewater. Heavy metals in sludge exist in four forms: acid-soluble, reducible, oxidizable, and residue; while heavy metals in wastewater are basically in the ion state. The principles ...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that step 1 is soaked in an acidic solution and subjected to microwave radiation, and then placed in an air bath constant temperature oscillator to vibrate; wherein the microwave power is 400W, and the microwave time is 10min. Other steps and parameters are the same as those in Embodiment 1.

Embodiment 1

[0020] Fly Ash Modification:

[0021] 1. Soak the fly ash in the acidic solution for 4 hours, then place it in an air bath constant temperature oscillator and shake it for 90 minutes at a temperature of 20°C and 250r / min. The H in the acidic solution + The concentration is 4mol / L, and the acid-ash ratio is 3ml:1g;

[0022] 2. Centrifuge at 10,000r / min for 10min, remove the acid solution and wash the acid-modified fly ash repeatedly with ultrapure water until neutral;

[0023] 3. Dry at 105°C to constant weight, crush and pass through a 100-mesh sieve, and then heat at 105°C for 2 hours to complete the fly ash modification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com