Antibacterial composite nanofiltration membrane, and preparation method and application thereof

A composite nanofiltration membrane and nano-silver technology, applied in the field of membrane separation, can solve problems such as microbial contamination, non-killing, and reduced membrane characteristics, and achieve good antibacterial performance, simple and energy-saving preparation process, and improved antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

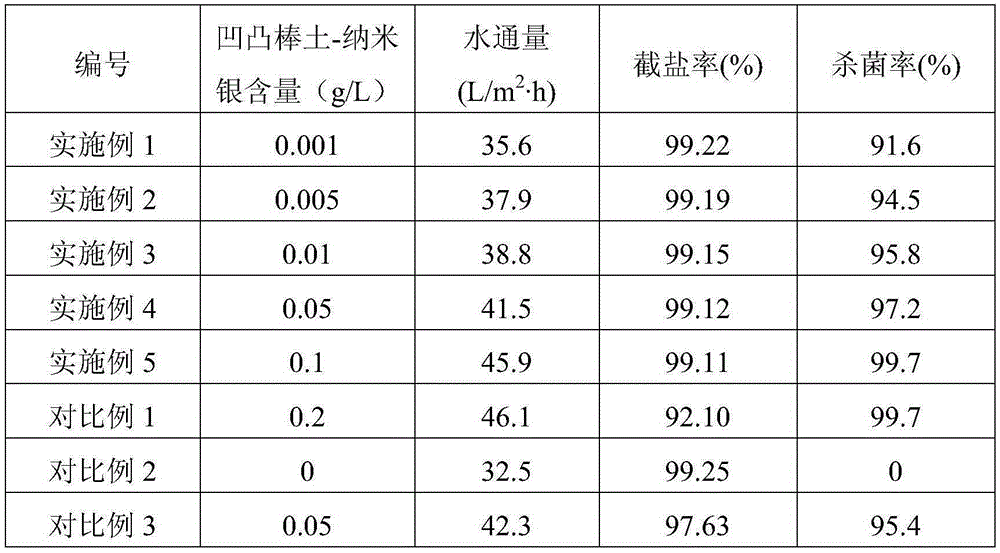

Embodiment 1

[0051] The specific steps for the preparation of attapulgite-nano silver composite inorganic antibacterial agent in the present embodiment are as follows: (1) take the attapulgite (AT) through thermal activation and dispersion treatment, and prepare attapulgite mass concentration into water with a mass concentration of 1%. suspension, (2) and silver nitrate solution (AgNO 3 / AT=17 / 100) into the attapulgite suspension, at 50°C, magnetically stirred for 1h, (3) spray-dry the attapulgite suspension at 200°C, and collect the obtained Composite powder, (4) Finally, calcining the obtained composite powder in a muffle furnace at 500° C. for 5 minutes to obtain attapulgite-nanometer silver composite inorganic antibacterial agent. The above-mentioned composite powder prepared by spray drying and the composite powder obtained after calcination were characterized by XRD and TEM respectively, and the results showed that the silver in the composite powder after spray drying was formed as A...

Embodiment 2

[0054] The specific steps for the preparation of attapulgite-nanometer silver composite inorganic antibacterial agent in the present embodiment are as follows: (1) take the attapulgite (AT) through thermal activation and dispersion treatment, and add distilled water to prepare attapulgite with a mass concentration of 5 % suspension, (2) then silver nitrate solution (AgNO 3 / AT=135 / 100) into the attapulgite suspension, at 90°C, magnetically stirred for 3h, (3) spray-dry the attapulgite suspension at 170°C, and collect the composite powder, (4) Finally, calcining the obtained composite powder at 400° C. for 15 minutes to obtain attapulgite-nanometer silver composite inorganic antibacterial agent. The above-mentioned composite powder prepared by spray drying and the composite powder obtained after calcination were characterized by XRD and TEM respectively, and the results showed that the silver in the composite powder after spray drying was formed as Ag 2 CO 3 form, and decompo...

Embodiment 3

[0057] In the present embodiment, the preparation steps of attapulgite-nano-silver composite inorganic antibacterial agent are as follows: (1) Weigh the attapulgite (AT) through thermal activation and dispersion treatment, and add distilled water to prepare attapulgite with a mass concentration of 10%. suspension, (2) and silver nitrate solution (AgNO 3 / AT=170 / 100) into the attapulgite suspension, stirred at 60°C for 1 hour, (3) spray-dried the attapulgite suspension at 150°C, and collected the composite powder obtained by spray drying , (4) Finally, calcining the obtained composite powder at 200° C. for 180 minutes to obtain attapulgite-nanometer silver composite inorganic powder. The above-mentioned composite powder prepared by spray drying and the composite powder obtained after calcination were characterized by XRD and TEM respectively, and the results showed that the silver in the composite powder after spray drying was formed as Ag 2 CO 3 form, and decomposes into Ag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com