Dish drying equipment for large restaurant

A technology for drying equipment and restaurants, used in cleaning equipment, drying solid materials, drying gas layout, etc., can solve the problems of long consumption time, labor-intensive, slow drying, etc., achieve thorough drying, improve service life, and fast speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

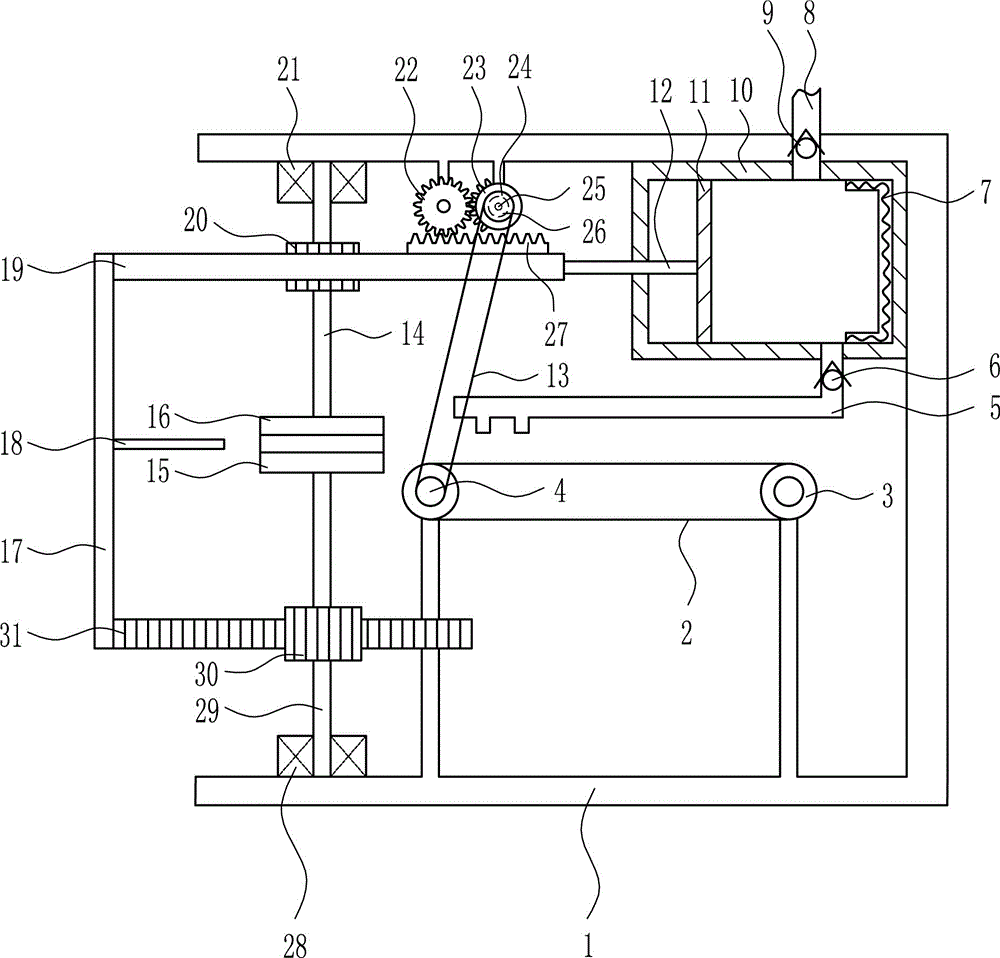

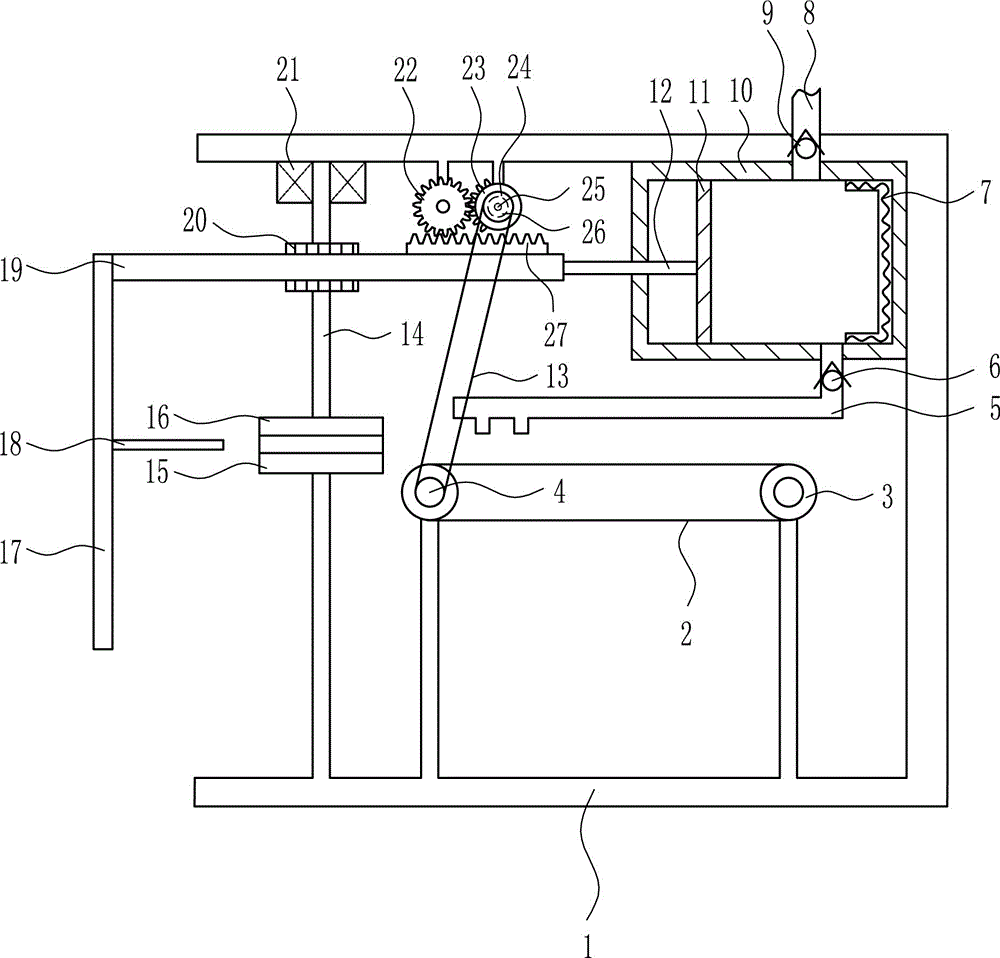

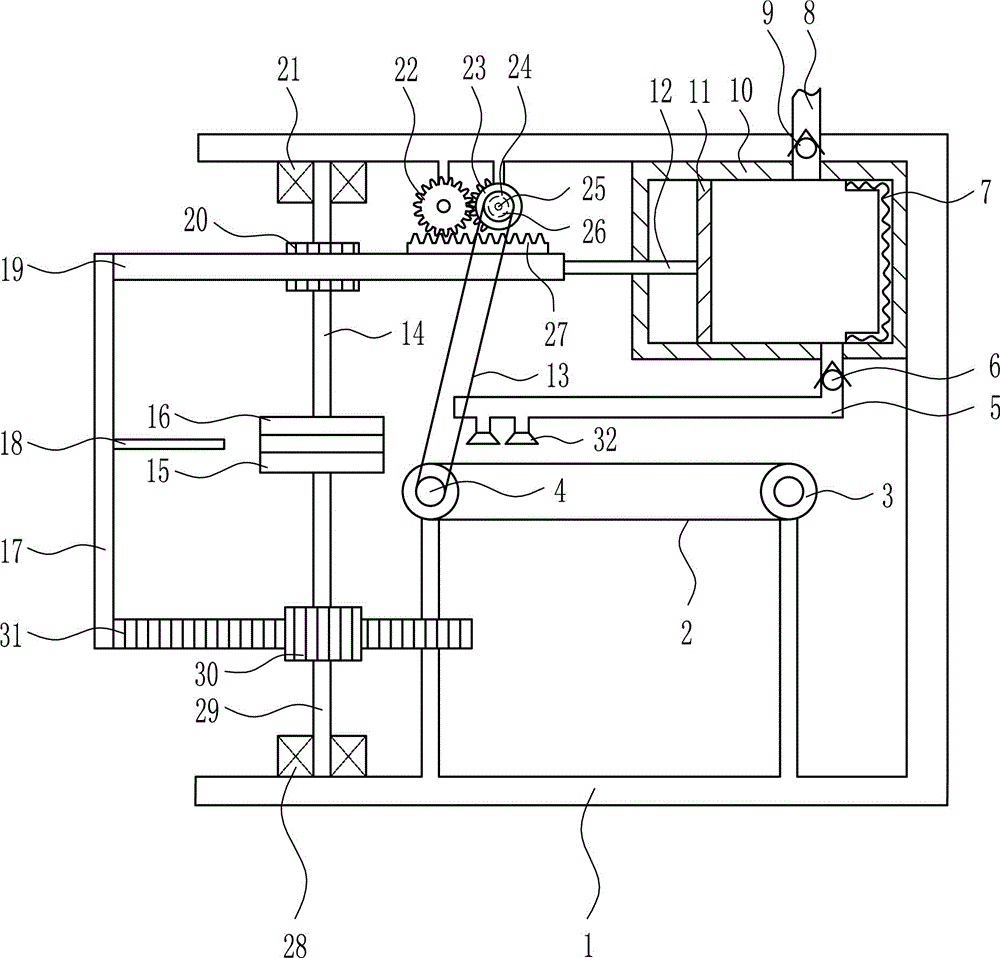

[0025] A large restaurant plate drying equipment, such as Figure 1-3 As shown, it includes a fixed frame 1, a transmission belt 2, a transmission wheel 3, a first pulley 4, an air outlet pipe 5, a first one-way valve 6, a heating wire 7, an air intake pipe 8, a second one-way valve 9, and a cylinder body. 10. Piston 11, moving rod 12, connecting belt 13, first rotating shaft 14, first wiping block 15, second wiping block 16, connecting plate 17, push rod 18, first rack 19, first complete gear 20, The first bearing seat 21, the second complete gear 22, the first incomplete gear 23, the second pulley 24, the second rotating shaft 25, the motor 26 and the second rack 27, the left side of the fixed frame 1 inner bottom is provided with the first wiper Block 15, fixed frame 1 inner bottom left and right sides are symmetrically provided with transmission wheel 3, is wound with transmission belt 2 on the transmission wheel 3, and transmission wheel 3 front side is provided with firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com