Preparation method of low-salt low-chloropropanol acid hydrolyzed vegetable protein

A plant protein and acid hydrolysis technology, which is applied in the field of food seasoning preparation, can solve the problems of economical and efficient preparation of plant protein seasoning, and achieve the effects of high degree of hydrolysis, reduced chloropropanol content, and reduced salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

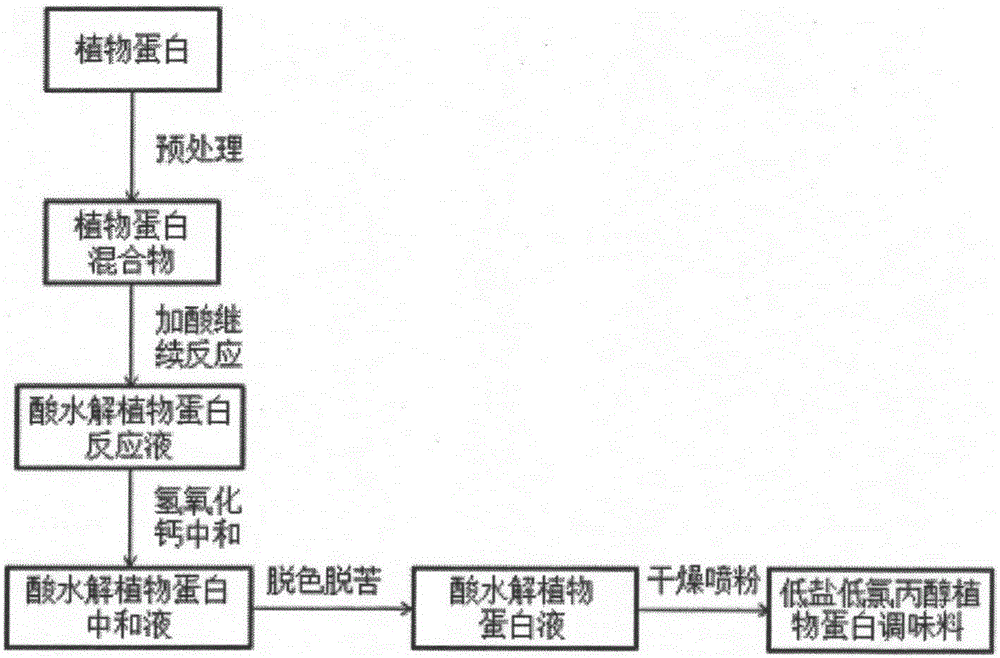

Image

Examples

Embodiment 1

[0027] Step 1: Take 200g of soybean protein, place it in 200g of sulfuric acid solution with a mass concentration of 30%, and stir and reflux for 1 hour.

[0028] Step 2: Mixing and reacting the pretreated soybean protein mixture with 200 g of sulfuric acid solution with a mass concentration of 30%, the reaction temperature is 90° C., and the reaction time is 8 hours to obtain an acid hydrolyzed soybean protein reaction solution;

[0029] Step 3: adding 85 g of calcium hydroxide to neutralize the acid-hydrolyzed soybean protein reaction liquid, and adjusting the pH to 5 with calcium hydroxide to obtain an acid-hydrolyzed soybean protein neutralizing liquid;

[0030] Step 4: Add 5‰ of the total weight of activated carbon to the acid-hydrolyzed soybean protein neutralization liquid, react at a constant temperature of 80°C for 1 hour, decolorize and debitterize, and vacuum filter to obtain an acid-hydrolyzed soybean protein liquid;

[0031] Step 5: The acid hydrolyzed soybean pro...

Embodiment 2

[0033] Step 1: Take 200g of wheat protein, place in 200g of sulfuric acid solution with a mass concentration of 50%, and stir and reflux for 1 hour.

[0034] Step 2: Mixing and reacting the pretreated wheat protein mixture with 200 g of sulfuric acid solution with a mass concentration of 50%, the reaction temperature is 100° C., and the reaction time is 6 hours to obtain an acid hydrolyzed wheat protein reaction solution;

[0035] Step 3: adding 145 g of calcium hydroxide to neutralize the acid-hydrolyzed wheat protein reaction liquid, and adjusting the pH to 5.5 with calcium hydroxide to obtain an acid-hydrolyzed wheat protein neutralizing liquid;

[0036] Step 4: Add 7‰ of the total weight of activated carbon to the acid-hydrolyzed wheat protein neutralization liquid, react at a constant temperature of 70°C for 0.5h, decolorize and debitter, and vacuum filter to obtain the acid-hydrolyzed wheat protein liquid;

[0037] Step 5: The acid hydrolyzed wheat protein liquid is inje...

Embodiment 3

[0039] Step 1: Take 1 kg of zein, place it in 1 kg of sulfuric acid solution with a mass concentration of 45%, and stir and reflux for 1 hour.

[0040] Step 2: Mixing and reacting the pretreated zein mixture with 1 kg of sulfuric acid solution with a mass concentration of 45%, the reaction temperature is 95° C., and the reaction time is 10 hours to obtain an acid hydrolyzed zein reaction solution;

[0041] Step 3: adding 670 g of calcium hydroxide to neutralize the acid-hydrolyzed zein reaction solution, and adjusting the pH to 4.9 with calcium hydroxide to obtain an acid-hydrolyzed zein neutralizing solution;

[0042] Step 4: Add 3‰ of the total weight of activated carbon to the acid-hydrolyzed zein neutralizing liquid, react at a constant temperature of 80°C for 1.5 hours, decolorize and debitter, and vacuum filter to obtain an acid-hydrolyzed zein liquid;

[0043] Step 5: The acid-hydrolyzed zein liquid is injected into the spray drying tower through a pressure pump, and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com