Kefir yoghourt with probiotic function and preparation method thereof

A kefir yogurt, functional technology, applied in the field of bioengineering, can solve the problems of kefir quality performance decline, poor starter activity, long curd time, etc., to increase the accumulation of beneficial ingredients and improve the liveness of probiotics Number, reduce the effect of fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

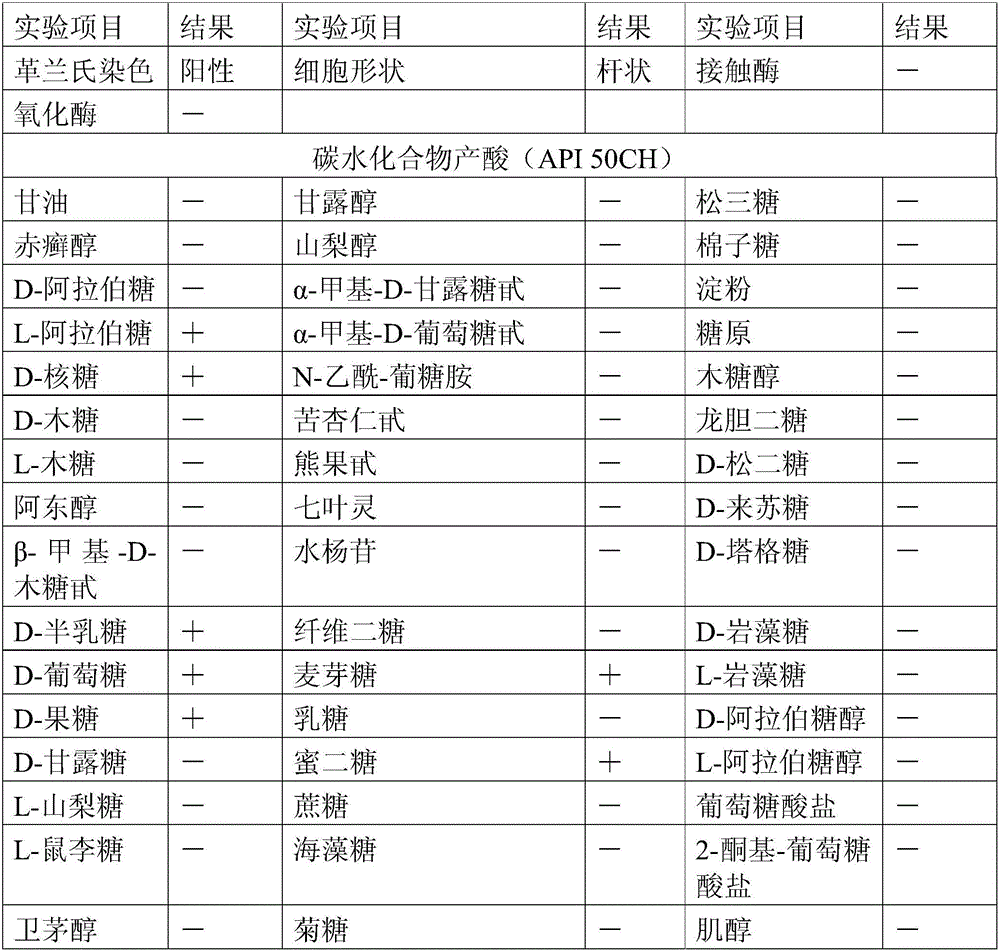

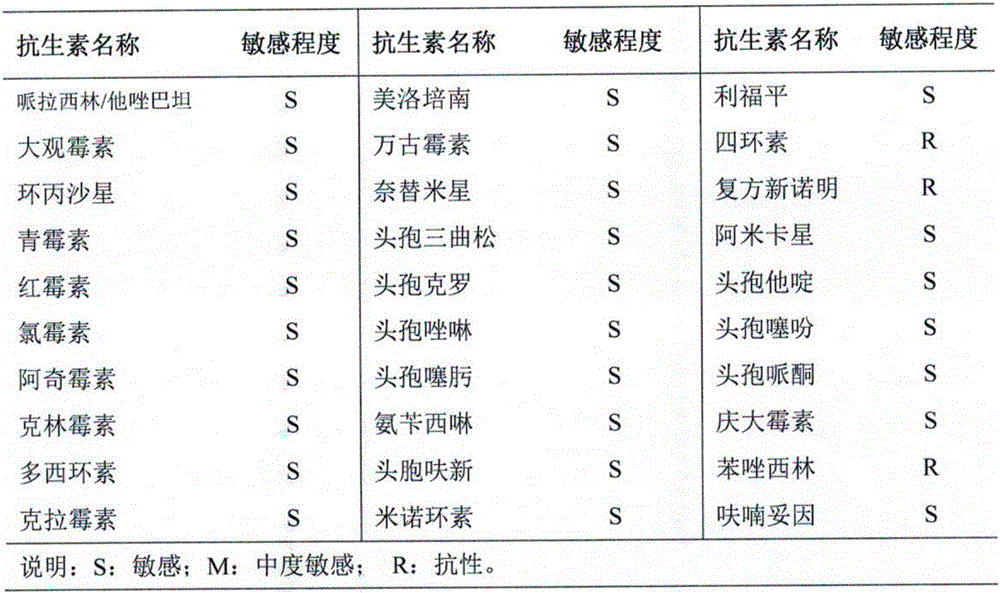

[0041] Caucasus yogurt Lactobacillus (Lactobacillus kefiri) JMCC0101 of the present invention, its screening method is carried out as follows:

[0042] ① Sample collection

[0043] Take 25mL of traditional fermented milk products from Dali, Yunnan, add them to 250mL of normal saline, mix well, and obtain samples;

[0044] ② Enrichment of samples

[0045] Take 2 mL of the sample, add it to 100 mL of LC liquid medium, and incubate at 35°C for 72 hours to obtain a culture solution;

[0046] ③Isolation and purification of bacterial strains;

[0047] a. Strain isolation

[0048] Take 1 mL of the culture solution and dilute it 100,000 times with 0.9% (percentage by weight and volume) sterile normal saline, and serially dilute 10 times -1 、10 -2 、10 -3 、10 -4 、10 -5 times to obtain the bacterial suspension;

[0049] Take the MRS agar medium, after melting, pour it into a petri dish, wait for it to cool and completely solidify, draw 0.1mL of bacterial suspension and spread it o...

Embodiment 2

[0079] This embodiment relates to a preparation method of kefir yoghurt with probiotic function, the method comprising the following steps:

[0080] 1) Ingredients: add stabilizer, galactomannan, and sweetener to raw milk, stir for 10-15 minutes until the auxiliary materials are completely dissolved, control the milk temperature below 15°C, store for less than or equal to 1 hour, and 15 minutes before sterilization minute to start stirring.

[0081] 2) Homogenization: Homogenization treatment is carried out at a temperature of 60±2°C, the primary pressure of homogeneous treatment is 17.5MPa, and the secondary pressure is 5MPa.

[0082] 3) Sterilization: Sterilize at a temperature of 93-98°C, and the sterilization time is 305±5s

[0083] 4) Cooling: Cool down the sterilized material liquid to 41.0±1.0°C, then put it into the fermenter

[0084] 5) Inoculation: activate the basic strain starter and Lactobacillus yoghurt JMCC0101 at room temperature for 30 minutes, add to the fe...

Embodiment 3

[0090] This example provides a method for preparing kefir yoghurt with probiotic function, which is basically the same as that of Example 2, except for the raw materials involved.

[0091] The raw materials involved in this example are: 920kg of raw milk, 1.5kg of hydroxypropyl distarch phosphate as a stabilizer, 85kg of sucrose as a sweetener, 2.9kg of galactomannan, 25DCU / t of Streptococcus thermophilus , Lactobacillus bulgaricus 50DCU / t, Lactobacillus Caucasus JMCC0101 45DCU / t.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com