Intermittent impacting type press roller

A pressing roller and impact technology, applied in the field of pressing rollers, can solve the problems of affecting seed germination and emergence, reducing work efficiency, insufficient pressing force, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

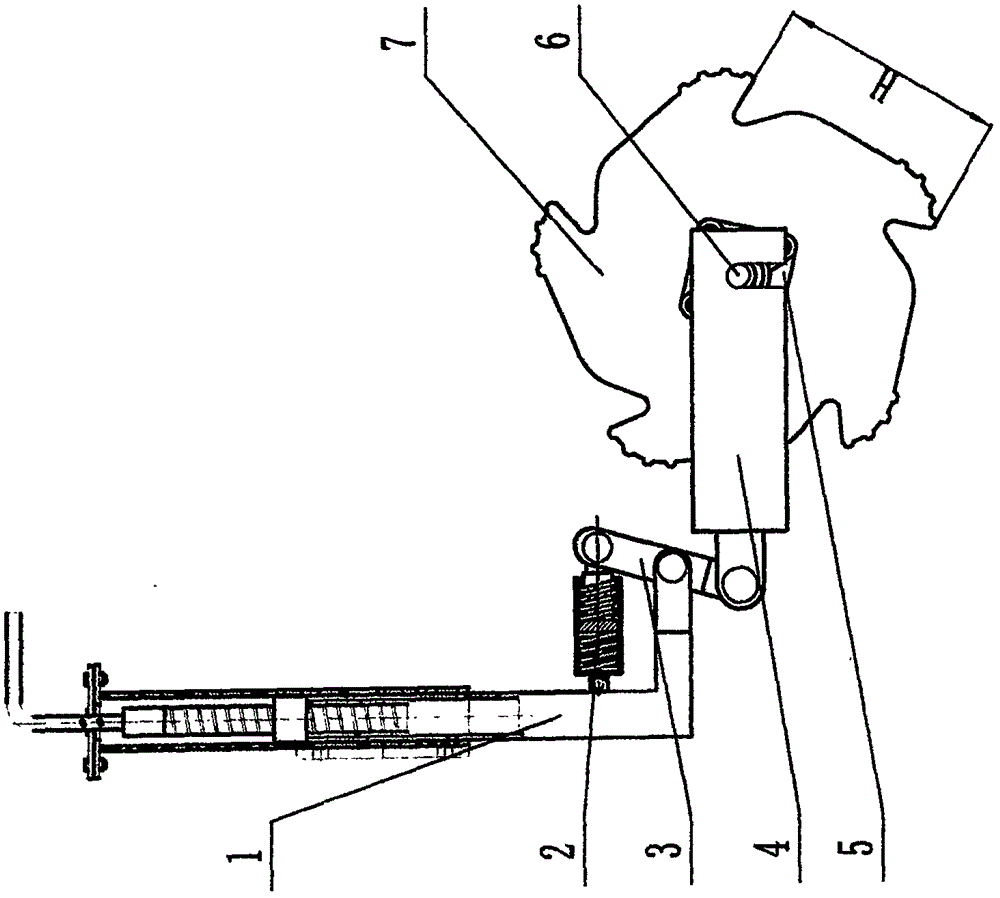

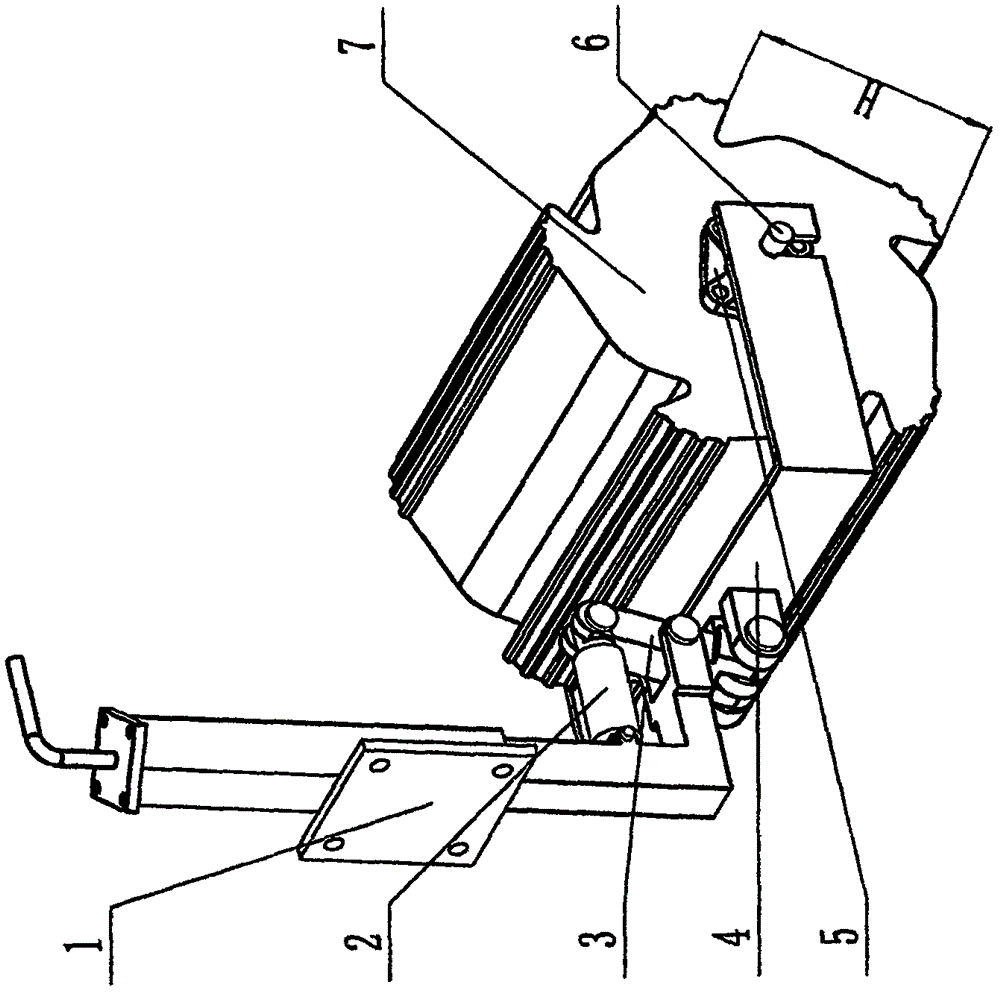

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An intermittent impact type pressure roller, on the bottom of the height adjustment frame assembly 1, a swing rod 3 is hingedly installed, on the lower side of the swing rod 3, a roller frame 4 is hingedly installed, and the roller shaft 6 is fitted on the roller On the frame 4, a non-cylindrical impact pressing roller 7 is rotatably installed on the roller shaft 6 through a bearing 5, and the outer surface of the non-cylindrical impact pressing roller 7 is evenly arranged at intervals along the direction of its axis. There are N boss-type lifting sections, and the chord length H of each boss-type lifting section in the circumferential direction is 220 mm or 90 mm. The front end of the buffer shock absorber 2 is hinged on the lower side of the height adjustment frame assembly 1, and the rear end of the buffer shock absorber 2 is hinged to the upper side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com