Temperature multi-model prediction function control method and device

A predictive function control and multi-model technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as difficult engineering applications, complex algorithms, and large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

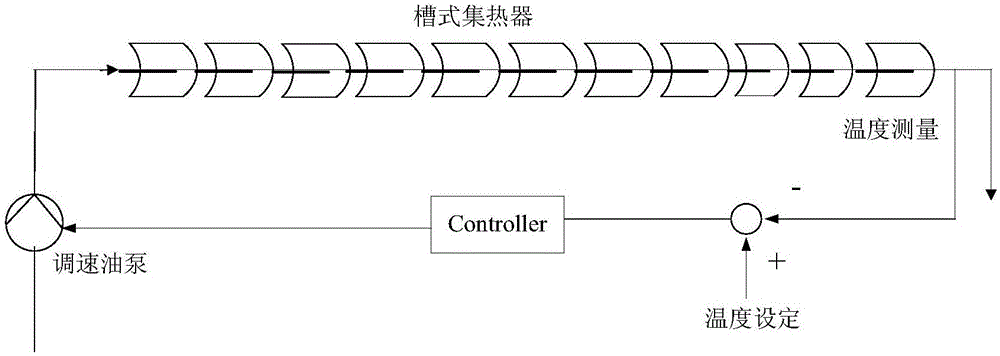

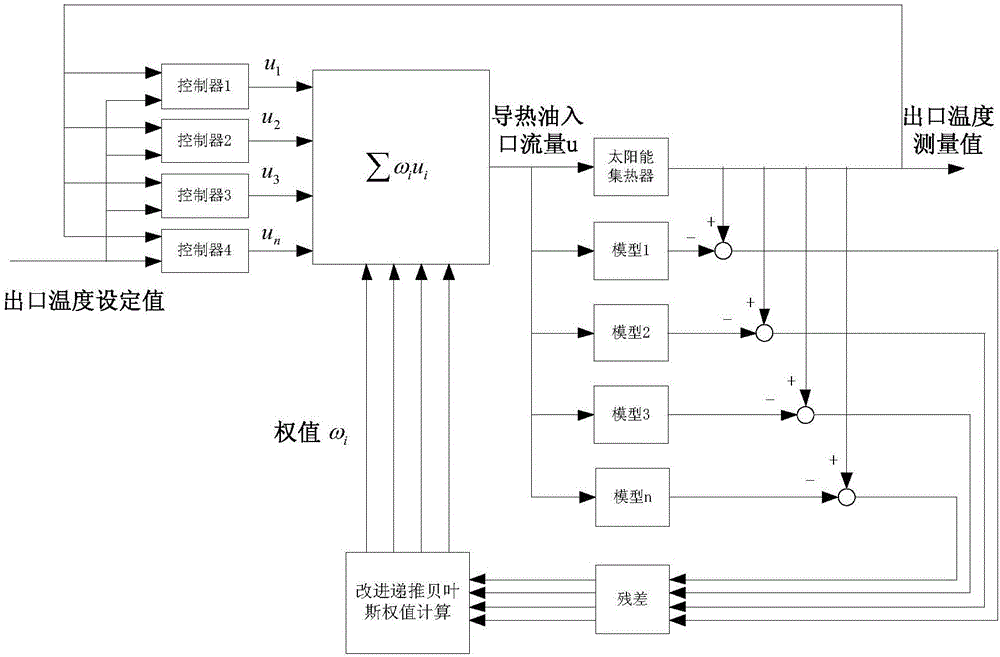

[0061] Since the controlled object of the heat transfer oil temperature at the collector outlet is a nonlinear object, in order to improve the control quality of the heat transfer oil outlet temperature, the present invention proposes a The temperature multi-model predictive function control method and device, this control algorithm is introduced into the heat transfer oil temperature control system for the first time such as figure 2 As shown, an effective temperature control of the heat transfer oil outlet is obtained.

[0062] Such as figure 1 As shown, the method includes the following steps:

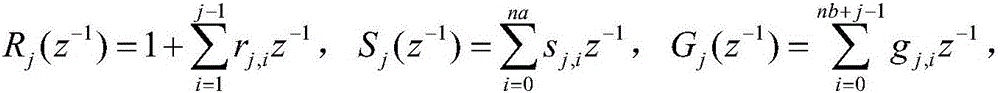

[0063] 1. Construct a transfer function model based on CARIMA description;

[0064] According to the characteristics of the controlled object of the heat transfer oil outlet temperature of the trough solar thermal power ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com