Mine radial automatic flow dividing device and control method thereof

A technology of automatic flow separation and control method, which is applied in chemical instruments and methods, grading, solid separation, etc. It can solve problems such as inability to sort minerals, complicated work sections, and difficult equipment processing, so as to achieve fast and complete screening, avoid accumulation, and save Effects of time and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

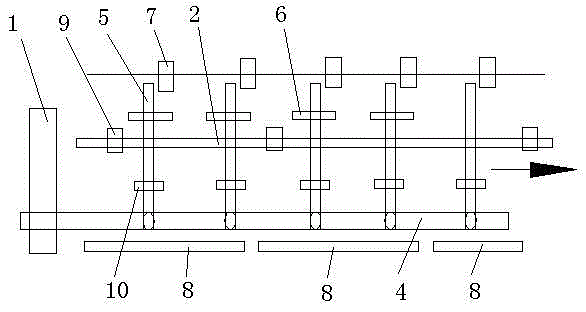

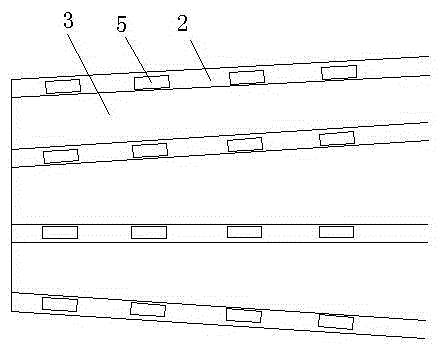

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

[0027] as attached figure 1 and 2 As shown, a kind of mine radial automatic diversion device of the present invention is connected with a power control device at one end, and the power control device controls the operation of the whole diversion device. One group, two conveying bars in each group are arranged in parallel and spaced apart from each other. This interval is used to push the rack to run, similar to the guide rail, pushing the rack to advance along the guide rail. The interval between each group of conveying bars Open to form a conveying gap, the conveying gap is used to make the minerals smaller than the gap fall to the conveyor belt set below, and the circular transmission device driven by the power control device is arranged under the conveyor belt, and the circular transmission device drives the rack to push the lower end of the rack It is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com