Half shaft used for rear bridge of electric automobile

A technology for rear axle axles and electric vehicles, which is applied to axles, wheels, vehicle parts, etc., can solve the problems of heavy workload of staff, increased use costs of axles, and increased energy consumption, saving materials and comprehensive manufacturing costs. The effect of reducing and saving processing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

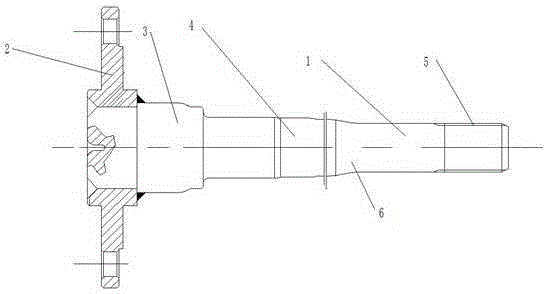

[0015] Such as figure 1 As shown, an electric vehicle rear axle half shaft of the present invention includes a half shaft body 1, a flange 2 is provided at one end of the half shaft body 1, and a transition section 3 and a bearing are arranged near the flange 2 The other end of the neck 4 and the shaft body 1 is provided with a spline 5, and the shaft body 1, the transition section 3 and the flange 2 are connected to form a rear axle half shaft.

[0016] Preferably, as a possible embodiment, the rear axle shaft is formed by welding the axle body 1 , the transition section 3 and the flange 2 .

[0017] Preferably, as another possible embodiment, a layer of phosphating layer 6 is provided on the surface of the axle shaft of the rear axle.

[0018] The half shaft used for the rear axle of an electric vehicle of the present invention has a reasonable structure, and the half shaft body 1 is formed by split welding. Compared with the common half shaft, it has the advantage of savin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com