Modular high density coal system oil shale quality promoting technology and quality promoting system

一种油页岩、高密度的技术,应用在模块化高密度煤系油页岩提质工艺及提质系统领域,能够解决灰渣多、加剧处理的成本、浪费时间等问题,达到工艺技术线路简洁明了、开发与利用重大、工艺流程简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

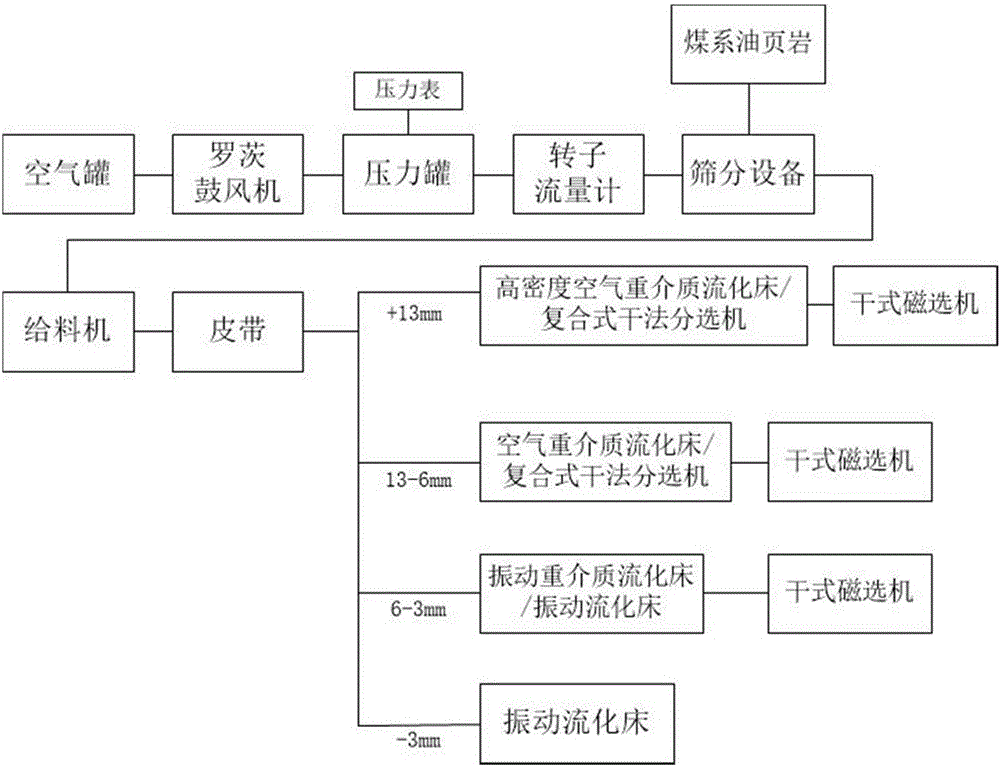

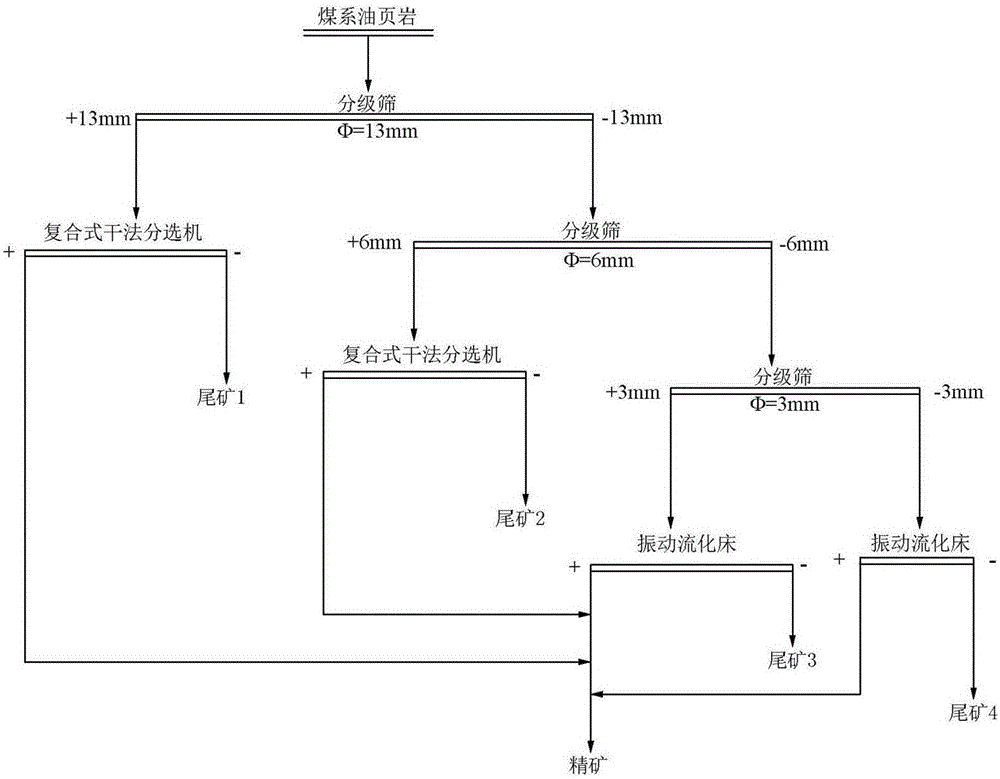

[0044] Example 1: When the moisture content of the oil shale is greater than 10%, the quality of the oil shale is upgraded without adding media, such as figure 2 Shown.

[0045] It mainly includes the following stages: +13mm sorting stage, 13-6mm sorting stage, 6-3mm sorting stage, -3mm sorting stage, medium recovery cycle stage;

[0046] The +13mm sorting stage includes screening the original 13mm, taking materials above +13mm, and sorting with a compound dry sorting machine to meet product requirements;

[0047] The 13mm-6mm sorting stage includes 6mm screening of materials below 13mm, and materials above 6mm to be sorted by a composite dry sorting machine to meet product requirements;

[0048] The 6-3mm sorting stage includes 3mm sieving the original material below 6mm, taking the material above 3mm and sorting with a vibrating fluidized bed to meet product requirements;

[0049] The -3mm sorting stage includes 3mm sieving the original material below 6mm, taking the materials below ...

Embodiment 2

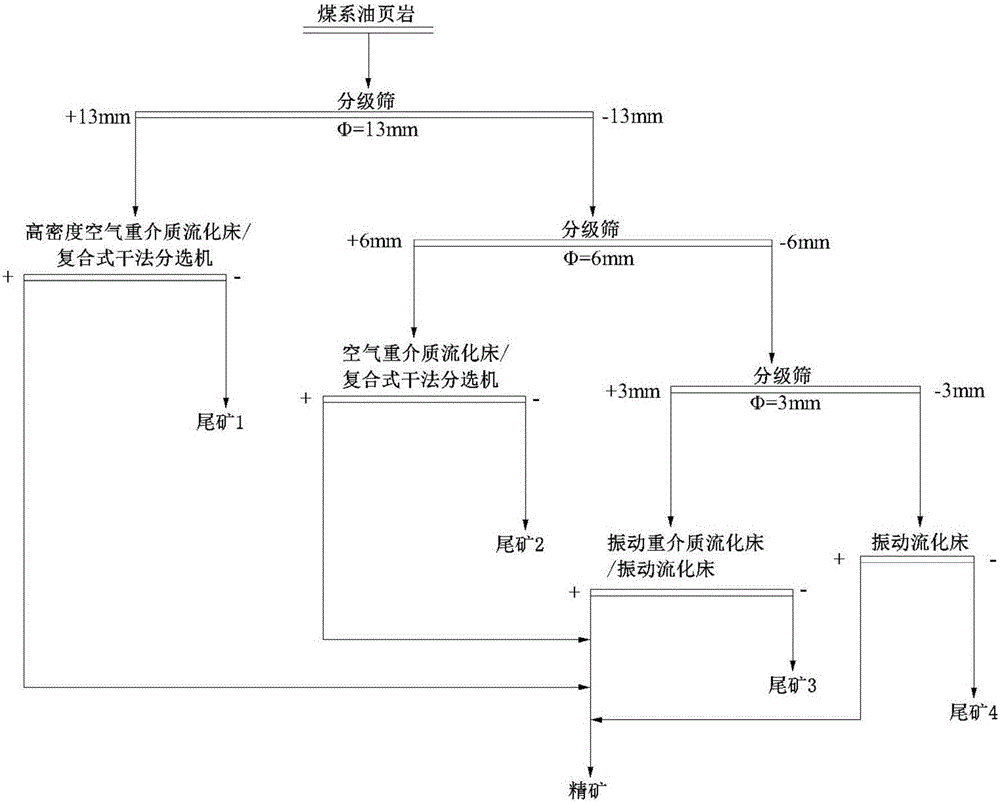

[0056] Example 2: When the moisture content of the oil shale is less than 10%, the quality of the oil shale is improved by a mediating process, such as image 3 Shown.

[0057] The present invention mainly includes the following stages: +13mm sorting stage, 13-6mm sorting stage, 6-3mm sorting stage, -3mm sorting stage, medium recovery cycle stage;

[0058] The +13mm sorting stage includes screening the original 13mm, taking materials above +13mm, and separating them with a high-density air dense medium fluidized bed to meet product requirements;

[0059] The 13mm-6mm sorting stage includes 6mm screening of materials below 13mm, taking materials above 6mm, and separating them with a high-density air heavy medium fluidized bed machine to meet product requirements;

[0060] The 6-3mm sorting stage includes 3mm screening of the original material below 6mm, taking the material above 3mm, using a vibrating heavy medium fluidized bed to meet product requirements;

[0061] The -3mm sorting stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com