Flexible substrate and manufacturing method thereof

A flexible substrate and manufacturing method technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of reducing the light reflectivity of the alignment mark, affecting the alignment success rate, reducing the coverage area, etc. problem, achieve the effect of avoiding etching residue, high alignment success rate, and reducing coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

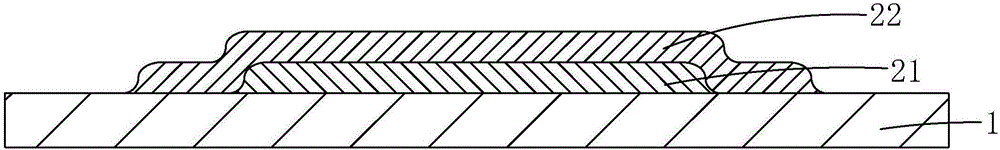

[0030] Please also see figure 1 and figure 2 , the present invention firstly provides a flexible substrate, including a first organic material layer 21 laid on the carrier substrate 1 , and a second organic material layer 22 completely covering the first organic material layer 21 . The coverage area of the second organic material layer 22 on the carrier substrate 1 is larger than the coverage area of the first organic material layer 21 on the carrier substrate 1, and the long side edge of the second organic material layer 22 surrounds the long side of the first organic material layer 21 edge.

[0031] Specifically, the carrier substrate 1 is preferably a glass substrate; the material of the first organic material layer 21 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com