Flue gas and air premixing pipe bundle self-cooling low-nitrogen combustion device and combustion method thereof

A low-nitrogen combustion, low-nitrogen burner technology, applied in the combustion method, flue gas combustion, burner and other directions, can solve the problems of high local flame temperature, excessive nitrogen oxide emissions, and large excess air coefficient, and reduce combustion. Temperature and surface flame temperature, control of nitrogen oxides generation, effect of reducing nitrogen oxides generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

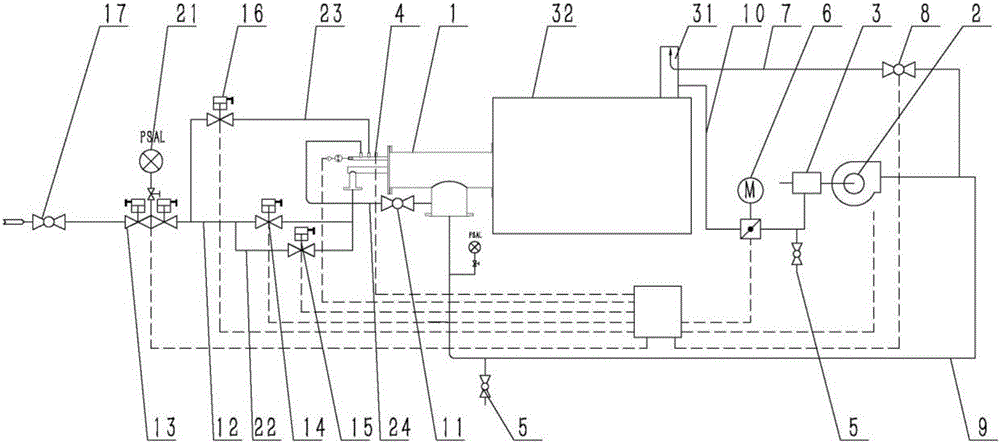

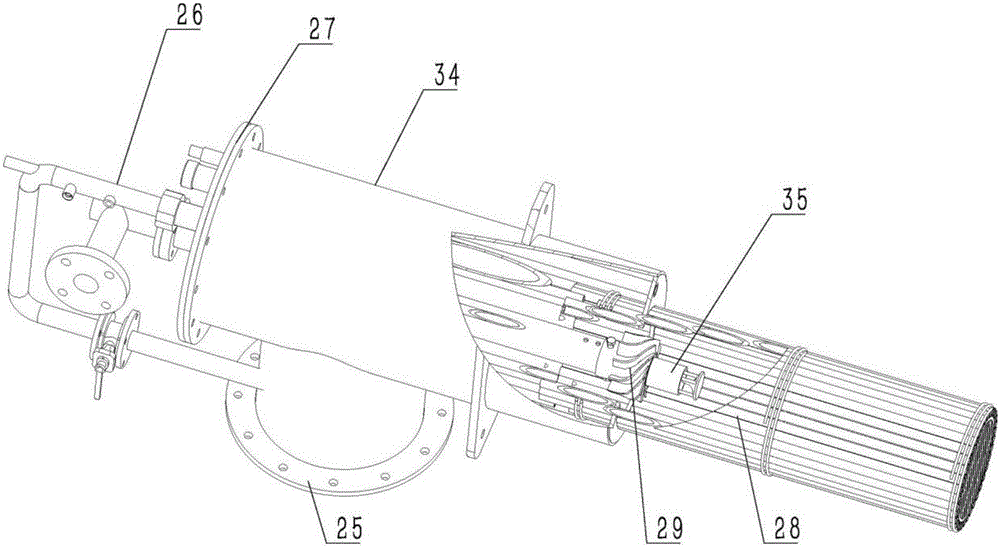

[0035] Example: see attached figure 1 , 2, a flue-air premixed tube bundle self-cooling low-nitrogen combustion device and its combustion method, which is provided with a gas pipeline, a blower 2, a flue-air premixed tube bundle self-cooling low-nitrogen burner 1; the air inlet of the blower is connected with a flue gas mixer 3. The outlet of the blower is connected with a smoke-air mixing pipe 9, and the smoke-air mixing pipe is connected with a smoke-air mixing ejector 7; the low-nitrogen burner is provided with a wind jacket 34, and a main gas nozzle is arranged in the wind jacket 35. The main gas nozzle passes through the flange at the rear end of the wind jacket, and is fixedly arranged in the middle of the wind jacket. A position-adjustable swirl piece 29 is arranged on the outer periphery of the front end, and a ring is arranged around the main gas nozzle in the wind jacket. The smoke and wind mixed gas cooling tube bundle 28, the smoke and wind mixed gas tube bundle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com