Chemical unpacking compression packer partial pressure string and oil well fracturing method

A compression packer and pressure divider technology, applied in sealing/packing, earth-moving drilling, wellbore/well components, etc., can solve the problems of difficult to unpack the fracturing packer and difficult to take out the pipe string.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

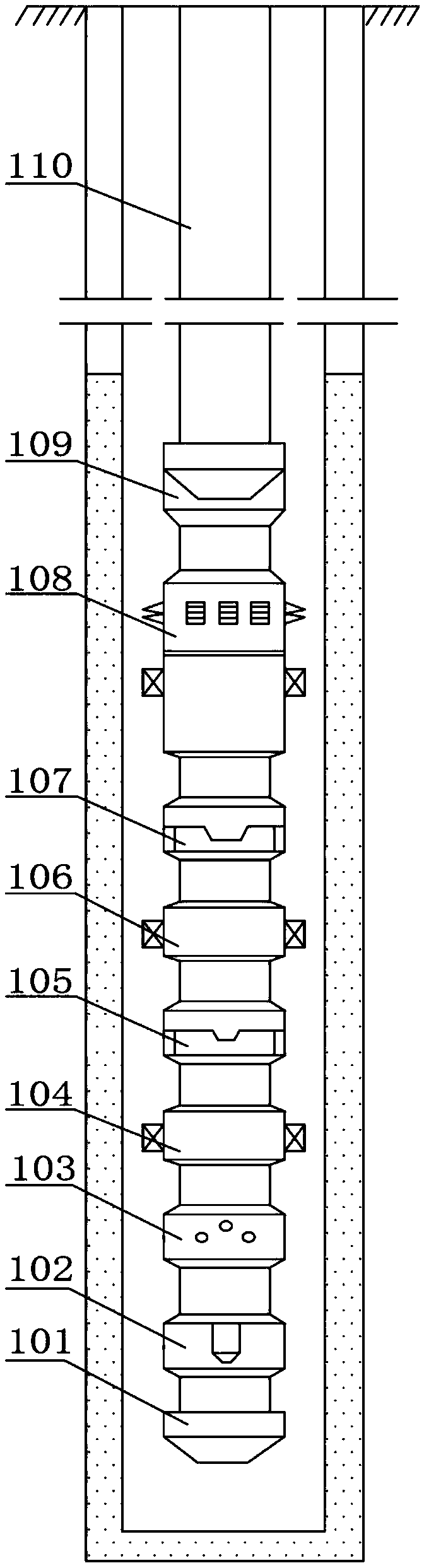

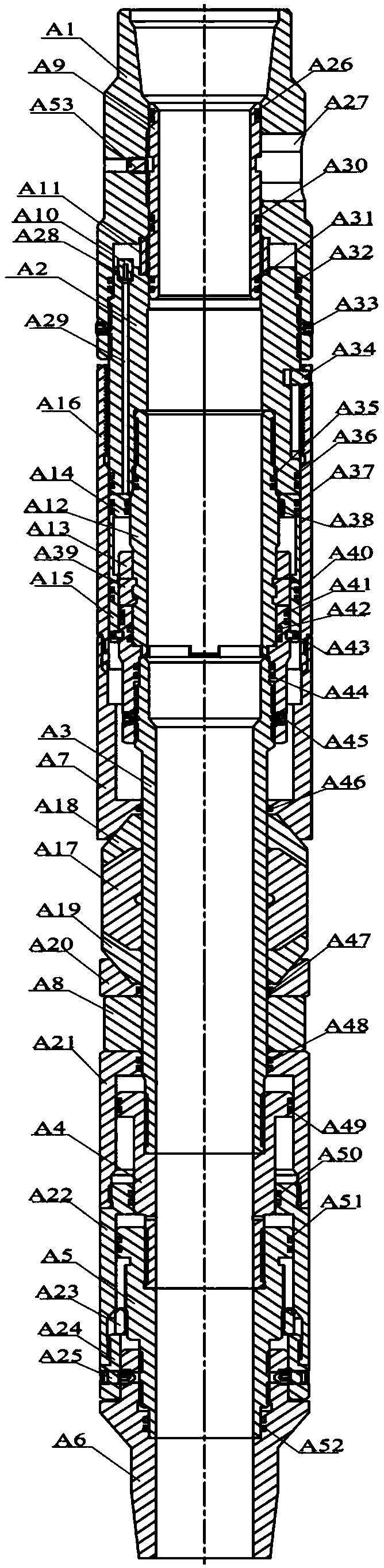

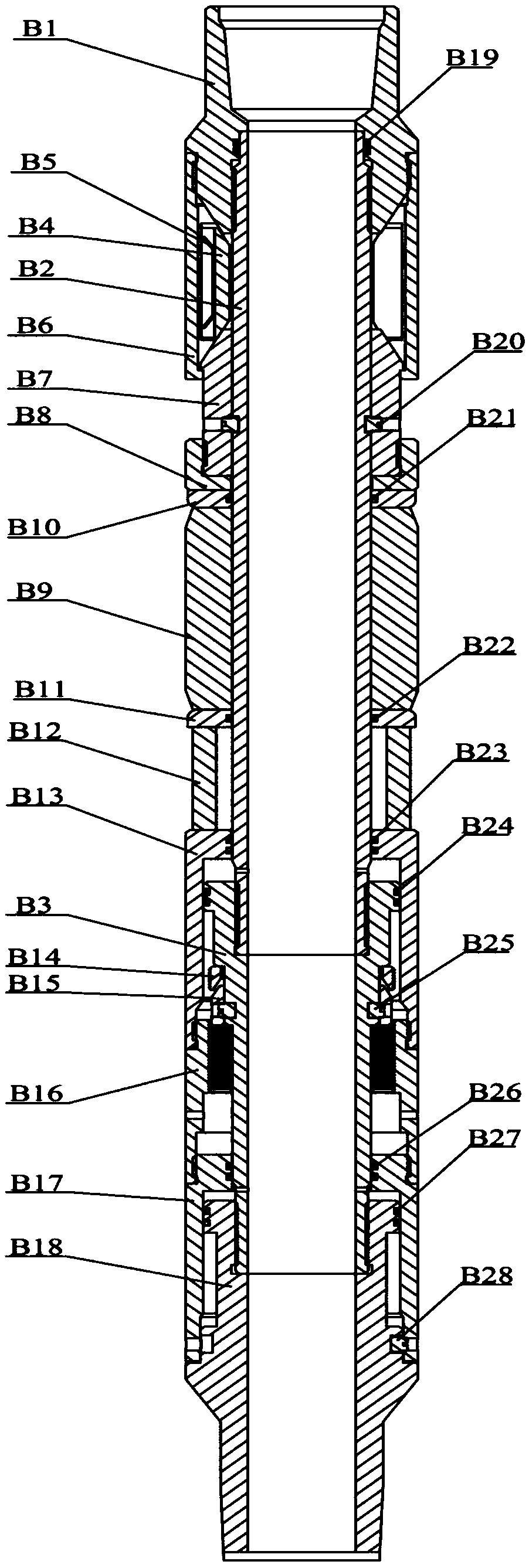

[0105] This embodiment provides a chemical unpacking compression packer pressure dividing string, such as figure 1 As shown, the pressure dividing string of the chemically unpacked compression packer includes a first chemically unpacked compression fracturing packer 104, a first ball-throwing sandblasting sliding sleeve 105, a second chemically unpacked compression fracturing packer Spacer 106, second pitching sandblasting sliding sleeve 107, chemical unsealing compression slip fracturing packer 108, differential pressure sandblasting sliding sleeve 103, safety joint 109, ball seat 102 and plug 101;

[0106] Plug 101, ball seat 102, differential pressure sandblasting sliding sleeve 103, first chemically unsealed compression fracturing packer 104, first pitching sandblasting sliding sleeve 105, second chemically unsealed compression fracturing packer The spacer 106, the second ball-dropping sandblasting sliding sleeve 107, the chemical desealing compression slip fracturing pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com