Design and construction technology of self-stabilized section steel suspended scaffold

A construction technology and scaffolding technology, which is applied in the direction of scaffolding for building structure support, building structure support, building structure support, etc., and can solve the problems of long period, large amount of embedded parts, and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

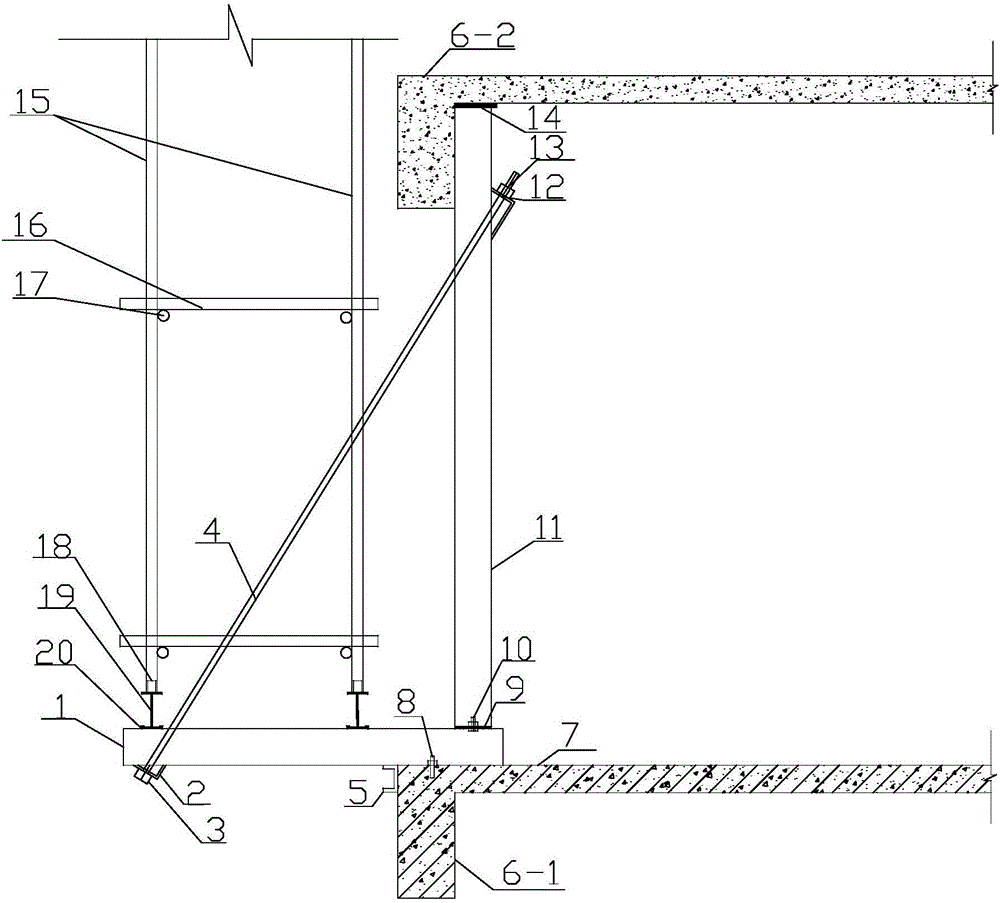

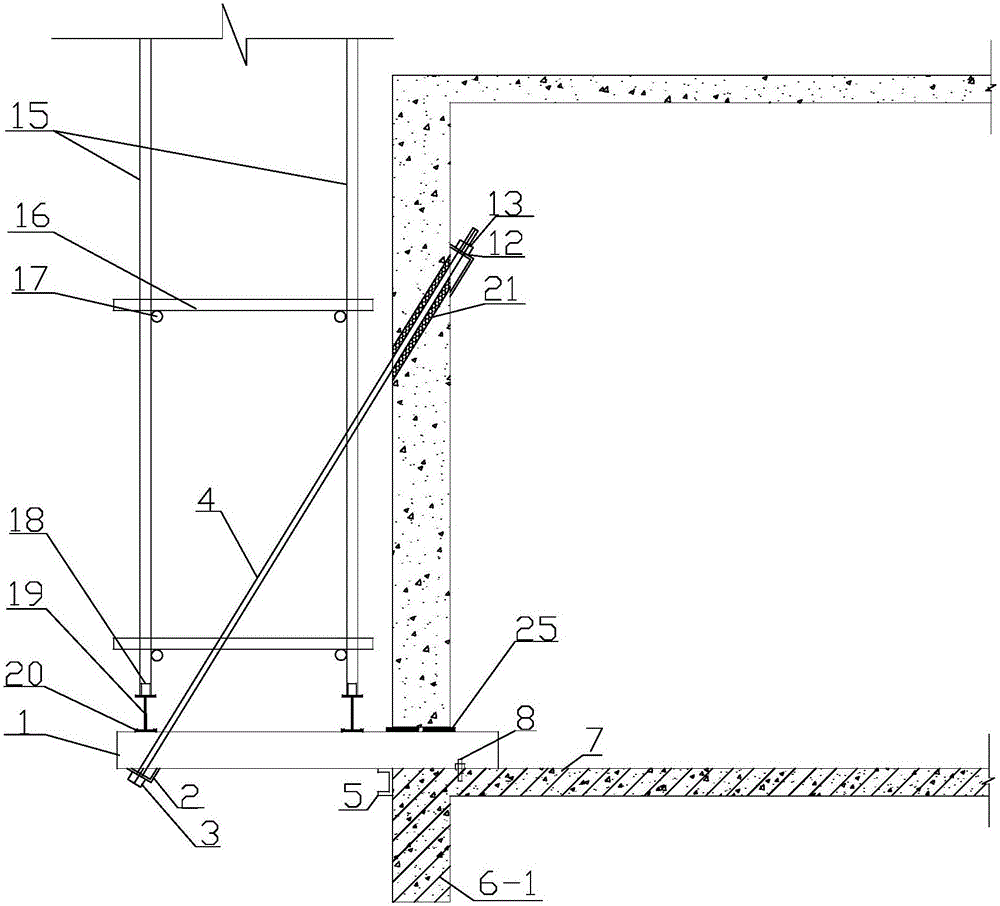

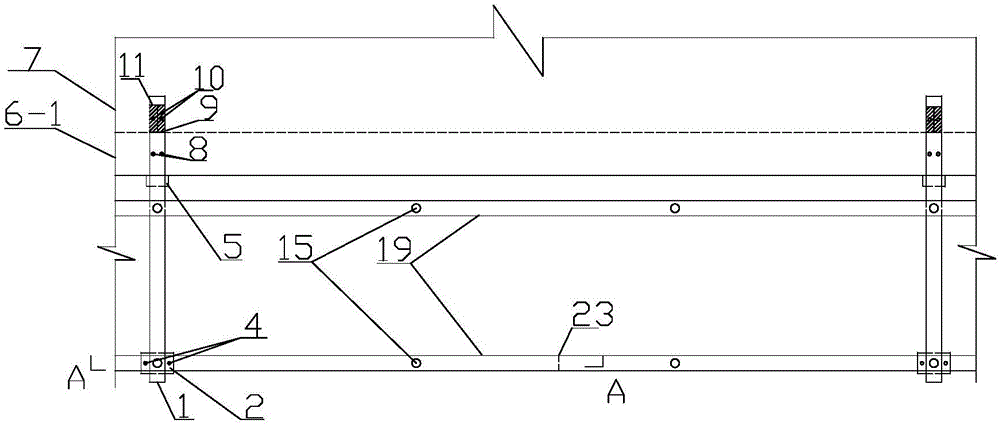

[0125] The present invention will be further described below in conjunction with accompanying drawing:

[0126] Such as Figure 1~4 Shown, self-stabilizing section steel suspension scaffold design and construction technology of the present invention:

[0127] 1. Construction drawing design of self-stabilizing steel suspension scaffolding:

[0128] See construction design for details Figure 1~4 ;

[0129] 2. Calculation of bearing capacity in cantilever state of main beam 1:

[0130] Before installing the steel bar 4, the main girder 1 is in a cantilever state, so the bearing capacity is calculated as follows:

[0131] 1. The maximum bending moment of cantilever main beam 1 is calculated according to the following formula:

[0132] In the formula: K 1 、K 2 - are the sub-item coefficients of live load and dead load respectively, taking 1.4 and 1.2 respectively;

[0133] q 1 ,q 2 —respectively, the construction live load and the dead load of the cantilever girder 1 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com