Method for sealing PHC pipe pile orifice through air bag

A technology of PHC pipe piles and airbags, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problem of insufficient contact between temporary thin steel plates and pipe openings, unsatisfactory blocking of water and soil, and large influence of sponge temperature factors, etc. problem, to achieve the effect of reducing the workload of hole cleaning, reducing the difficulty of hole cleaning, and sufficient market supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] PHC pipe pile aperture airbag plugging method of the present invention, concrete steps are:

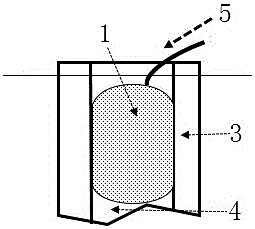

[0016] First, select a suitable rubber airbag 1 (such as a bladder), put the airbag 1 into the orifice of the pipe hole 4 of the pile 3, and the trachea 2 faces upwards ( figure 1 shown);

[0017] Then use an air pump to inject air 5 into the air bag to expand its volume so that it fits closely with the pipe wall of the pipe pile 3 ( figure 2 shown), so as to block the pipe hole 4 of the pipe pile 3 and prevent water and soil from flowing into the pipe hole 4 of the pipe pile 3;

[0018] Before the concrete core is filled, deflate 6 and recover the air bag 1 ( image 3 shown).

[0019] 1 material of air bag is rubber material. The airbag 1 is placed near the orifice of the pipe hole 4 of the pipe pile 3, lower than the orifice, to prevent it from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com