Drying system and manufacturing method thereof

A drying system and the technology of the air-inducing part, applied in the field of drying, can solve the problems of reducing and troublesome washing and drying machine performance, and achieve the effect of improving the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

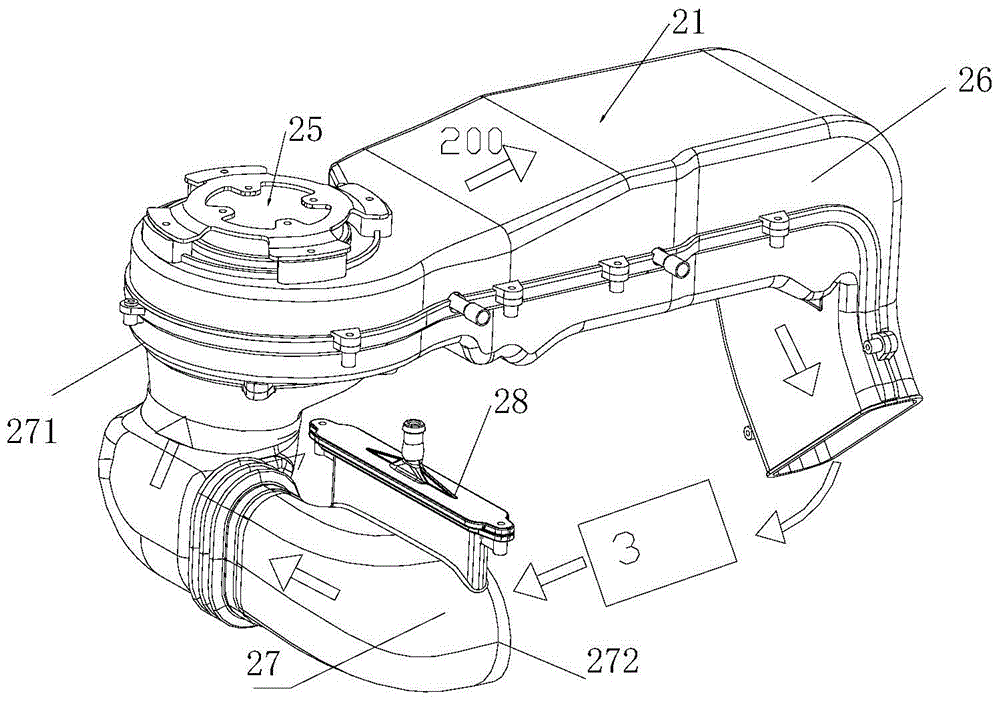

[0032] by figure 1 The illustrated drum type washer dryer 100 is taken as an example for description, refer to figure 1 , 4 , the drum type washing and drying machine 100 includes a cabinet 1, a drying system 2, a drum 3 and a water inlet channel 4, the drying system 2, the drum 3 and the water inlet channel 4 are all placed inside the cabinet 1, and the cabinet 1 includes The front wall 101 and rear wall (not shown) that are arranged oppositely and the side wall 102 and the top wall connected between the front wall 101 and the rear wall; the drum 3 is arranged inside the box body 1, and the drum 3 includes an outer drum 31 And the inner drum 32, the outer drum 31 is assembled and fixed with the box body, the inner drum 32 is rotatably connected with the outer drum 31 and the inner drum 32 is in fluid communication with the outer drum 31; the drying system 2 is arranged inside the box body 1 and Close to the top wall (not shown) of the box body 1 , the two ends of the drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com