Method for preparing and regenerating sphingomonas sp protoplast

A technology of protoplast and welan gum, applied in the field of microbial engineering, can solve the problems of complex operation, difficult conditions for wall removal and regeneration, etc., and achieve the effects of simple operation, strong repeatability and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

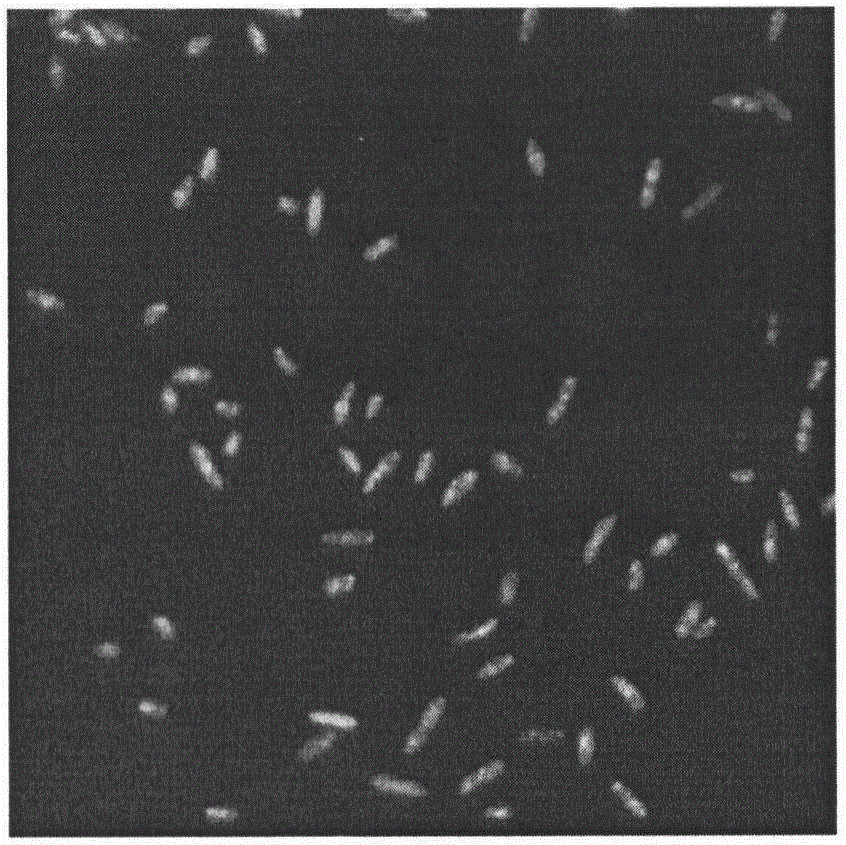

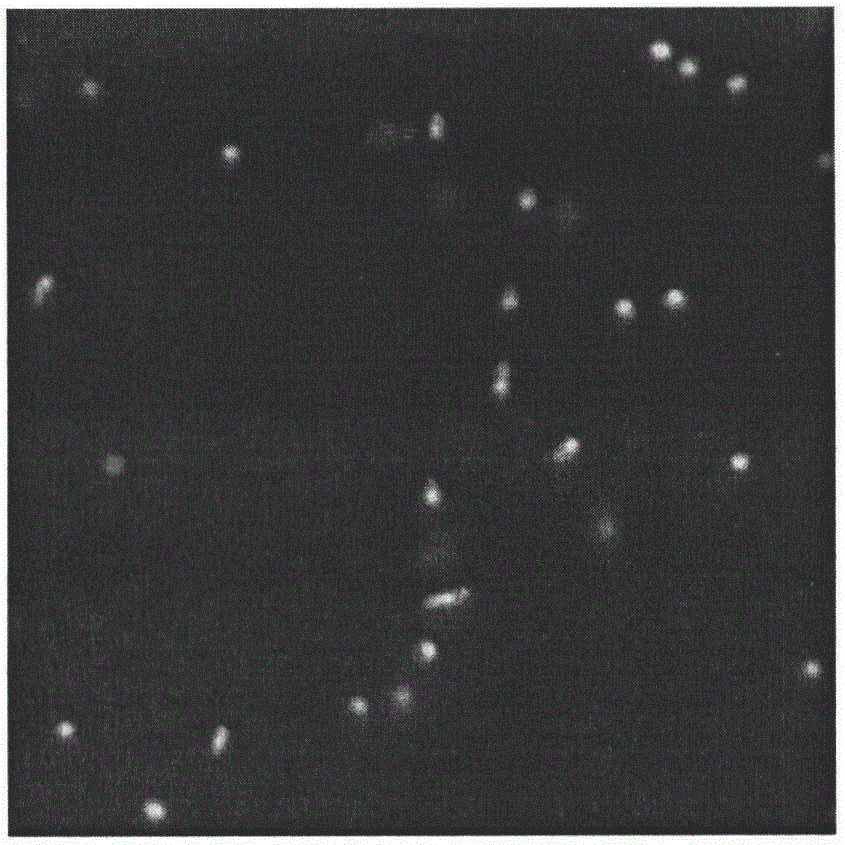

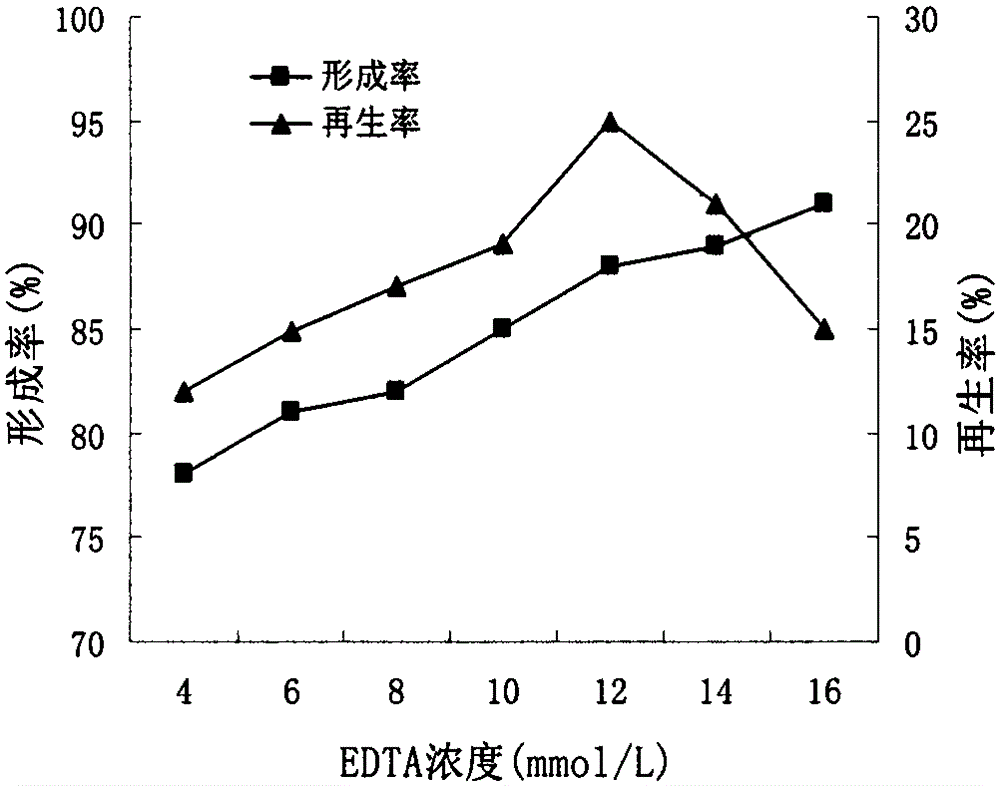

[0027] Take the preserved strain Sphingomonas sp, streak it on the slant of the test tube under aseptic conditions, and incubate at a constant temperature of 30°C for 72h. Rinse the bacteria on the slant of the test tube with 5 mL of sterile water, inoculate it into 100 mL of liquid medium for the inoculum, cultivate it on a shaker at 30 ° C for 10 h at 180 r / min, and add 12 mmol / L EDTA for treatment. The bacterial solution was taken and centrifuged at 8000r / min for 5min, the supernatant was discarded, the bacterial cells were washed with phosphate buffer, and the cell morphology was observed under a microscope ( figure 1 ). Suspend the bacteria in SMM buffer, then dilute with sterile water, spread the medium on the plate, and culture at 30°C for 4 days to obtain the number of colonies A (total number of colonies). Under the same conditions, centrifuge again and discard the supernatant, suspend the cells with 45μg / mL lysozyme, incubate at 28°C for 25min, centrifuge at 4000r / m...

Embodiment 2

[0033] Take the preserved strain Sphingomonas sp, streak it on the slant of the test tube under aseptic conditions, and incubate at a constant temperature of 30°C for 72h. Rinse the bacteria on the slant of the test tube with 5 mL of sterile water, inoculate it into 100 mL of liquid medium for the inoculum, cultivate it on a shaker at 30 ° C for 10 h at 180 r / min, and add 12 mmol / L EDTA for treatment. The bacterial solution was centrifuged at 8000r / min for 5min, the supernatant was discarded, and the bacterial cells were washed with phosphate buffer. Suspend the bacteria in SMM buffer, suspend the cells with 125μg / mL lysozyme, incubate at 37°C for 30min, centrifuge at 4000r / min for 10min, discard the supernatant, wash with hypertonic buffer to remove the enzyme, and the protoplasts obtained during this process The body formation rate was 88.0%, and the regeneration rate was 25.0%.

Embodiment 3

[0035] Take the preserved strain Sphingomonas sp, streak it on the slant of the test tube under aseptic conditions, and incubate at a constant temperature of 30°C for 72h. Rinse the bacteria on the slant of the test tube with 5 mL of sterile water, inoculate it into 100 mL of liquid medium for the inoculum, cultivate it on a shaker at 30 ° C for 10 h at 180 r / min, and add 12 mmol / L EDTA for treatment. The bacterial solution was centrifuged at 8000r / min for 5min, the supernatant was discarded, and the bacterial cells were washed with phosphate buffer. Suspend the bacteria in SMM buffer, suspend the cells with 45μg / mL lysozyme, incubate at 37°C for 30min, centrifuge at 4000r / min for 10min, discard the supernatant, wash with hypertonic buffer to remove the enzyme, and the protoplasts obtained during this process The body formation rate was 73.0%, and the regeneration rate was 31.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com