Modification of white carbon black by co-using AEO and silane coupling agent, and method for compounding modified white carbon black and rubber

A technology of silane coupling agent and white carbon black is applied in the field of inorganic nano powder modification, which can solve the problems of complex alkoxy groups and complex use conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

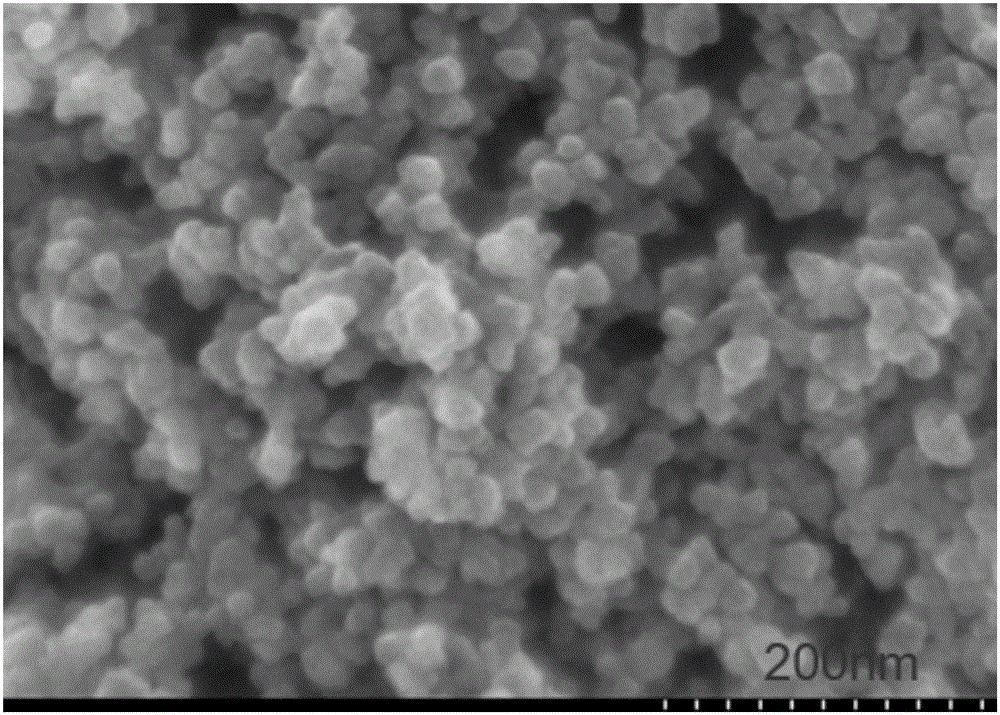

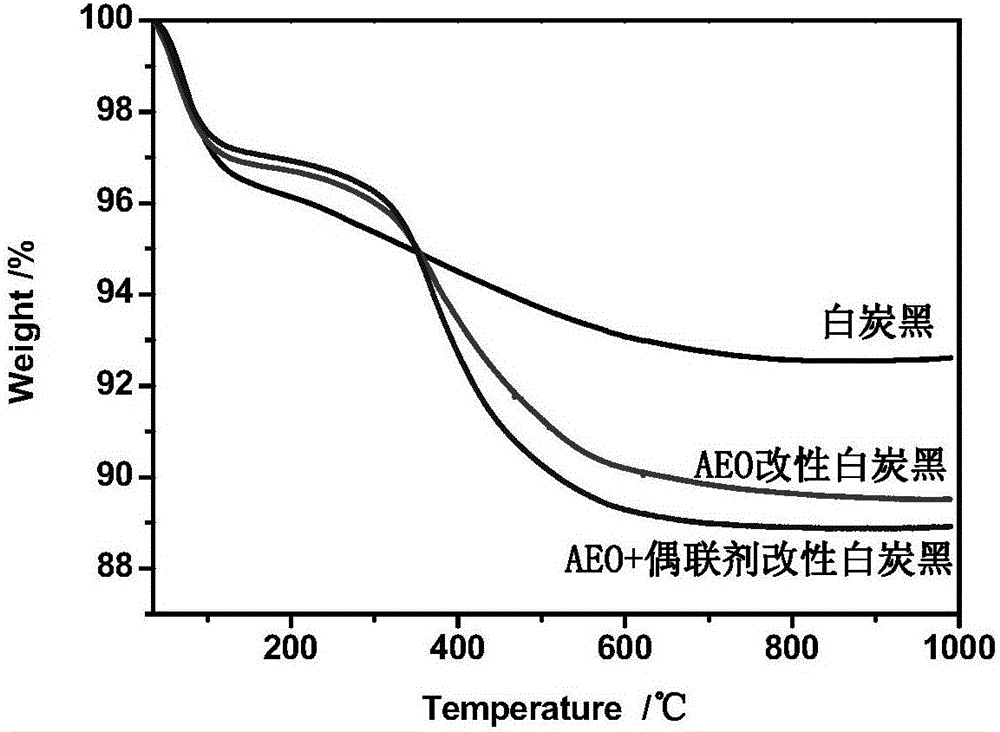

[0058] Take silica K160 powder and water and stir and mix at a mass percentage of 10:90, and further use high-speed stirring to stir the silica suspension at a speed of 5000rpm for 9 hours to obtain uniform and stable silica‐ Water suspension, the dispersion state of silica in water is good. Take 500g of the silica-water suspension, heat in a water bath while stirring (500rpm) in a beaker, to 55°C, and ensure that the temperature is stable. To this silica-water suspension, 5 g of a silane coupling agent (Si69) was added, followed by 6.5 g of AEO-9, kept in a water bath and stirred, and allowed to react for 2 hours. The modified white carbon black suspension is spray-dried and dehydrated to obtain dry organic modified white carbon black powder. The powder was extracted with an organic solvent for thermal gravimetric and infrared analysis, and compared with the thermal gravimetric and infrared results of unmodified silica and only 5g of AEO‐9 modified silica, so as to determine...

Embodiment 2

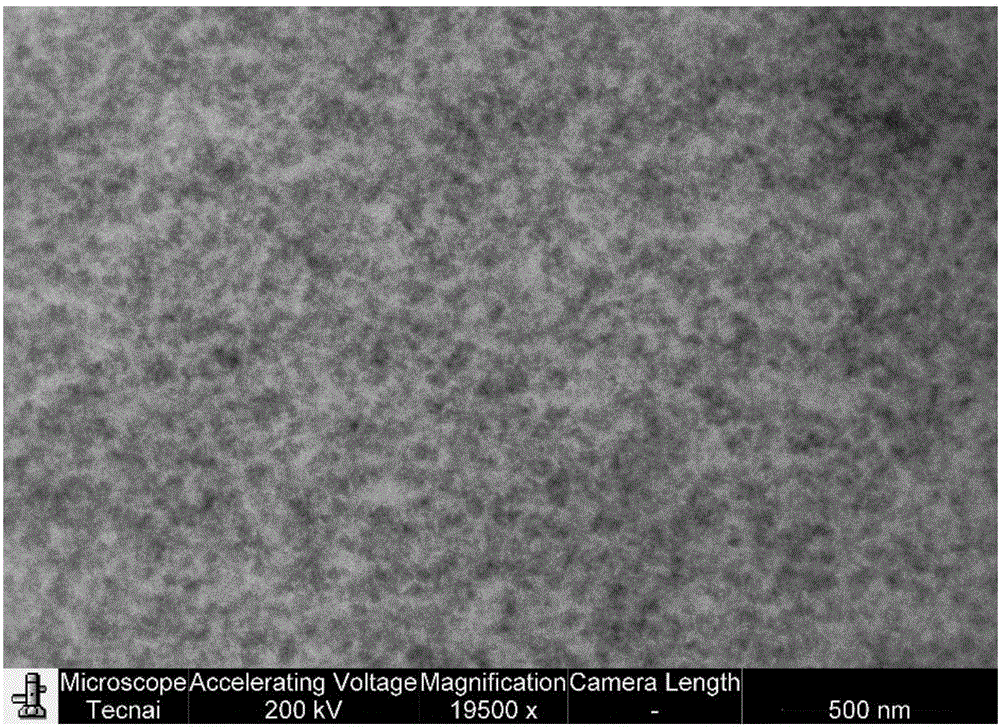

[0060] Take silica K160 powder and water and stir and mix at a mass percentage of 10:90, and further use high-speed stirring to stir the silica suspension at a speed of 5000rpm for 9 hours to obtain uniform and stable silica‐ Water suspension, the dispersion state of silica in water is good. Take 1000 g of the silica-water suspension, heat it in a water bath while stirring in a beaker, to 80° C., and ensure that the temperature is stable. To this silica-water suspension, 10 g of a silane coupling agent (Si75) was added, followed by 10 g of AEO-7, and the mixture was reacted for 3 hours while maintaining a water bath and stirring. The modified white carbon black suspension is spray-dried and dehydrated to obtain dry organic modified white carbon black powder. Get this white carbon black powder body 60g, add in the banbury mixer and blend with 100g natural rubber, the obtained white carbon black content is 50phr (being that white carbon black and natural rubber latex dry glue m...

Embodiment 3

[0064] Take the white carbon black Z2000 suspension slurry and mix it with water, adjust the white carbon black solid mass to 15% of the total mass of the suspension and stir and mix. This white carbon black suspension is further stirred at a speed of 3000rpm using high-speed stirring for 6 hours, with This obtains a uniform and stable silica-water suspension, and the dispersion state of silica in water is good. Take 1000g of the silica-water suspension, heat it in a water bath while stirring in a beaker, to 65°C, and ensure that the temperature is stable. To this silica-water suspension, 4.5 g of a silane coupling agent (KH590) was added, followed by 15 g of AEO-12, and the mixture was reacted for 4 hours while maintaining the water bath and stirring. The modified white carbon black suspension is dehydrated by spray drying to obtain dry modified white carbon black powder. Get this white carbon black powder 79.1g, divide and join in the emulsion polystyrene butadiene rubber t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com